|

ON-BOARD DIAGNOSTIC TEST [L8, LF]

id0102b1801000

DTC Reading Procedure

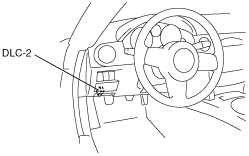

1. Connect the M-MDS to the DLC-2.

amxzzw00000604

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Then, select the “Retrieve CMDTCs” and perform procedures according to directions on the M-MDS screen.

4. Verify the DTC according to the directions on the M-MDS screen.

5. After completion of repairs, clear all DTCs stored in the PCM, while referring to “AFTER REPAIR PROCEDURE”. (See AFTER REPAIR PROCEDURE [L8, LF].)

Pending Trouble Code Access Procedure

1. Connect the M-MDS to the DLC-2.

amxzzw00000604

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Then, select the “Retrieve CMDTCs” and perform procedures according to directions on the M-MDS screen.

4. Retrieve the pending trouble codes according to the directions on the M-MDS screen.

Freeze Frame PID Data Access Procedure

1. Connect the M-MDS to the DLC-2.

amxzzw00000604

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Then, select the “Retrieve CMDTCs” and perform procedures according to directions on the M-MDS screen.

4. Retrieve the freeze frame PID data according to the directions on the M-MDS screen.

Freeze frame data table (mode2, mode12) table

|

Freeze frame data item |

Unit |

Description |

Corresponding PID data monitor item |

|||||

|---|---|---|---|---|---|---|---|---|

|

FUELSYS1

|

Open Loop/Closed Loop/OL-Drive/OL-Fault/CL-Fault

|

Fuel system status

|

FUELSYS

|

|||||

|

LOAD

|

%

|

Calculated engine load

|

—

|

|||||

|

ECT

|

°C

|

°F

|

Engine coolant temperature

|

ECT

|

||||

|

SFT1

|

%

|

Short term fuel trim

|

SHRTFT1

|

|||||

|

LFT1

|

%

|

Long term fuel trim

|

LONGFT1

|

|||||

|

MAP

|

kPa

|

Bar

|

psi

|

Manifold absolute pressure

|

MAP

|

|||

|

RPM

|

RPM

|

Engine speed

|

RPM

|

|||||

|

VS

|

KPH

|

MPH

|

Vehicle speed

|

VSS

|

||||

|

SPARKADV

|

°

|

Ignition timing

|

SPARKADV

|

|||||

|

IAT

|

°C

|

°F

|

Intake air temperature

|

IAT

|

||||

|

MAF

|

g/sec

|

Mass airflow

|

MAF

|

|||||

|

TP

|

%

|

Throttle valve position No.1

|

TP1

|

|||||

|

RUNTM

|

hh:mm:ss

|

Time from engine start

|

—

|

|||||

|

EGRPCT

|

%

|

Target EGR valve position

|

SEGRP_DSD

|

|||||

|

EVAPPCT

|

%

|

Purge solenoid valve controlled value

|

EVAPCP

|

|||||

|

WARMUPS

|

—

|

Number of warm-up cycle after DTC cleared

|

—

|

|||||

|

CLRDIST

|

Miles

|

Mileage after DTC cleared

|

—

|

|||||

|

BARO

|

kPa

|

Bar

|

psi

|

Barometric pressure

|

BARO

|

|||

|

CATTEMP11

|

°C

|

°F

|

Estimated catalytic converter temperature

|

CATT11_DSD

|

||||

|

VPWR

|

V

|

Module supply voltage

|

VPWR

|

|||||

|

ALV

|

%

|

Engine load

|

LOAD

|

|||||

|

TP_REL

|

%

|

Relative throttle position

|

TP REL

|

|||||

|

TP_B

|

%

|

Throttle valve position No.2

|

TP2

|

|||||

|

APP_D

|

%

|

Accelerator pedal position No.1

|

APP1

|

|||||

|

APP_E

|

%

|

Accelerator pedal position No.2

|

APP2

|

|||||

|

TAC_PCT

|

%

|

Target throttle valve position

|

ETC_DSD

|

|||||

On-Board System Readiness Tests Access Procedure

1. Connect the M-MDS to the DLC-2.

amxzzw00000604

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Then, select the “***SUP” and “***EVAL” PIDs in the PID selection screen.

4. Monitor those PIDs and check it system monitor is completed.

PID/DATA Monitor and Record Procedure

1. Connect the M-MDS to the DLC-2.

amxzzw00000604

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Select the PID from the PID table.

4. Verify the PID data according to the directions on the screen.

Diagnostic Monitoring Test Results Access Procedure

1. Connect the M-MDS to the DLC-2.

amxzzw00000604

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Verify the diagnostic monitoring test result according to the directions on the screen.

Simulation Function Procedure

1. Connect the M-MDS to the DLC-2.

amxzzw00000604

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Select the simulation items from the PID table.

4. Perform the simulation function, inspect the operations for each parts.