|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

-

Note

-

• Recording can be facilitated using the screen capture of the PC function.

• Record the freeze frame data/snapshot data.

|

—

|

Go to the next step.

|

|

2

|

VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

|

3

|

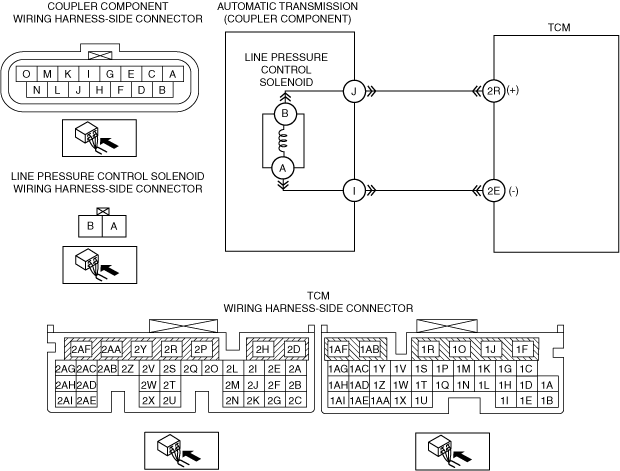

INSPECT TCM CONNECTOR FOR POOR CONNECTION

• Switch the ignition off.

• Disconnect the TCM connector.

• Inspect for poor connection at TCM terminals 2R and 2E (such as damaged/pulled-out pins, corrosion).

• Are terminals normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector and/or terminal, then go to Step 13.

|

|

4

|

INSPECT RESISTANCE OF LINE PRESSURE CONTROL SOLENOID CIRCUIT

• Inspect for resistance between TCM terminals 2R and 2E (wiring harness-side).

• Is the resistance within 5.0—5.6 ohms?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 7.

|

|

5

|

INSPECT LINE PRESSURE CONTROL SOLENOID CIRCUIT FOR SHORT TO GROUND

• Disconnect the coupler component connector.

• Inspect for continuity between TCM terminals (wiring harness-side) and body ground.

-

― Terminal 2R and body ground

― Terminal 2E and body ground

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Line pressure control solenoid terminal B—TCM terminal 2R

• Line pressure control solenoid terminal A—TCM terminal 2E

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

Go to Step 13.

|

|

No

|

Go to the next step.

|

|

6

|

INSPECT LINE PRESSURE CONTROL SOLENOID CIRCUIT FOR SHORT TO GROUND

• Inspect for continuity between coupler component terminals (wiring harness-side) and body ground.

-

― Terminal J and body ground

― Terminal I and body ground

• Is there continuity?

|

Yes

|

Repair or replace the coupler component, then go to Step 13.

|

|

No

|

Go to Step 13.

|

|

7

|

INSPECT COUPLER COMPONENT CONNECTOR FOR POOR CONNECTION

• Switch the ignition off.

• Disconnect the coupler component connector.

• Inspect for poor connection at coupler component terminals J and I (such as damaged/pulled-out pins, corrosion).

• Are terminals normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector and/or terminal, then go to Step 13.

|

|

8

|

INSPECT RESISTANCE OF LINE PRESSURE CONTROL SOLENOID CIRCUIT

• Inspect the resistance between coupler component (transmission case side) terminals J and I.

• Is the resistance within 5.0—5.6 ohms?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 10.

|

|

9

|

INSPECT LINE PRESSURE CONTROL SOLENOID CIRCUIT FOR OPEN CIRCUIT

• Inspect for continuity between TCM terminals and coupler component terminals (wiring harness-side).

-

― Terminal 2R and terminal J

― Terminal 2E and terminal I

• Is there continuity?

|

Yes

|

Go to Step 13.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• TCM terminal 2R—Coupler component terminal J

• TCM terminal 2E—Coupler component terminal I

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 13.

|

|

10

|

INSPECT LINE PRESSURE CONTROL SOLENOID CONNECTOR FOR POOR CONNECTION

• Disconnect the line pressure control solenoid connector.

• Inspect for poor connection at line pressure control solenoid terminals A and B (such as damaged/pulled-out pins, corrosion).

• Are terminals normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector and/or terminal, then go to Step 13.

|

|

11

|

INSPECT LINE PRESSURE CONTROL SOLENOID

• Inspect the line pressure control solenoid.

• Is the line pressure control solenoid normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the control valve body, then go to Step 13.

|

|

12

|

INSPECT LINE PRESSURE CONTROL SOLENOID CIRCUIT FOR OPEN CIRCUIT

• Inspect for continuity between coupler component terminals and line pressure control solenoid terminals (wiring harness-side).

-

― Terminal J and terminal B

― Terminal I and terminal A

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the coupler component, then go to the next step.

|

|

13

|

VERIFY SAME DTC IS NOT PRESENT

• Always reconnect all disconnected connectors.

• Clear the DTC using the M-MDS.

• Perform the following procedure to ensure that the DTC has been resolved:

-

1. Start the engine.

2. Warm-up the engine and transmission.

3. Drive the vehicle in D position and make sure that the gears shift smoothly from 1GR to 6GR.

• Perform the DTC inspection using the M-MDS.

• Is the same DTC present?

|

Yes

|

Replace the TCM, then go to the next step.

|

|

No

|

Go to the next step.

|

|

14

|

VERIFY DTC TROUBLESHOOTING COMPLETED

• Clear the DTC using the M-MDS.

• Perform the DTC inspection using the M-MDS.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|