|

1

|

VERIFY OTHER RETRACTABLE HARDTOP CONTROL MODULE DTCs

• Clear the DTC for the retractable hardtop control module using the M-MDS.

• Retrieve the retractable hardtop control module DTCs using the M-MDS.

• Is the DTCs U3000:44/U3000:45/U3000:49 displayed?

|

Yes

|

Replace the retractable hardtop control module, then go to Step 6.

|

|

No

|

Go to the next step.

|

|

2

|

VERIFY RETRACTABLE HARDTOP CONTROL MODULE POWER SUPPLY VOLTAGE

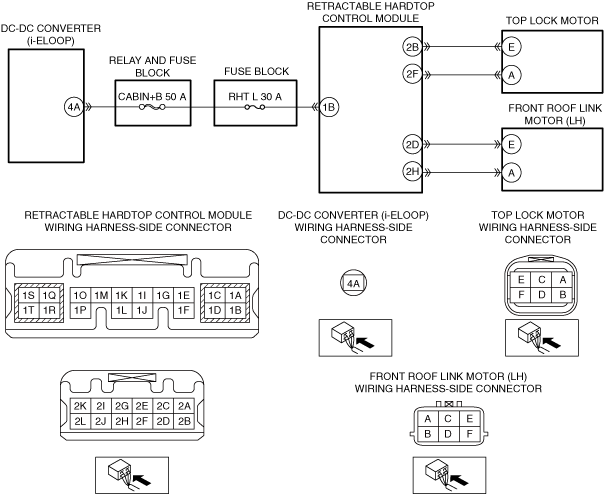

• Measure the voltage at the following terminal (wiring harness-side):

-

― Retractable hardtop control module terminal 1B

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the CABIN+B 50 A fuse, RHT L 30 A fuse.

• Any fuse is blown:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between the following:

-

• Retractable hardtop control module terminal 1B and DC-DC converter (i-ELOOP) terminal 4A

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has a short to ground.

• Replace the fuse.

• Any fuse is damaged:

-

― Replace the fuse.

• All fuses are normal:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between the following:

-

• Retractable hardtop control module terminal 1B and DC-DC converter (i-ELOOP) terminal 4A

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

Go to Step 6.

|

|

3

|

INSPECT TOP LOCK MOTOR CIRCUIT FOR SHORT TO GROUND

• Switch the ignition off.

• Disconnect the negative battery terminal.

• Disconnect the retractable hardtop control module and top lock motor connectors.

• Inspect for continuity between the following terminals (wiring harness-side) and body ground:

-

― Top lock motor terminal E

― Top lock motor terminal A

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Retractable hardtop control module terminal 2B and top lock motor terminal E

• Retractable hardtop control module terminal 2F and top lock motor terminal A

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

Go to Step 6.

|

|

No

|

Go to the next step.

|

|

4

|

INSPECT TOP LOCK MOTOR CIRCUIT FOR OPEN CIRCUIT

• Verify that the retractable hardtop control module and top lock motor connectors are disconnected.

• Inspect the wiring harness for continuity between the following terminals (wiring harness-side):

-

― Retractable hardtop control module terminal 2B and top lock motor terminal E

― Retractable hardtop control module terminal 2F and top lock motor terminal A

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Retractable hardtop control module terminal 2B and top lock motor terminal E

• Retractable hardtop control module terminal 2F and top lock motor terminal A

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 6.

|

|

5

|

INSPECT TOP LOCK MOTOR

• Inspect the top lock motor.

• Is the top lock motor normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the top lock motor, then go to the next step.

|

|

6

|

VERIFY THAT REPAIRS HAVE BEEN COMPLETED

• Always reconnect all disconnected connectors.

• Connect the negative battery terminal.

• Clear the DTC for the retractable hardtop control module using the M-MDS.

• Retrieve the retractable hardtop control module DTCs using the M-MDS.

• Is the same Pending DTC present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the retractable hardtop control module.

Go to the next step.

|

|

No

|

Go to the next step.

|

|

7

|

VERIFY IF OTHER DTCs DISPLAYED

• Are any other DTCs displayed?

|

Yes

|

Repair or replace the malfunctioning part according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|