|

amxzzw00005692

SMART CITY BRAKE SUPPORT [REVERSE] (SCBS R) DOES NOT OPERATE/OPERATES INCORRECTLY [SMART CITY BRAKE SUPPORT [REVERSE] (SCBS R)]

id1503b1003600

Possible Causes

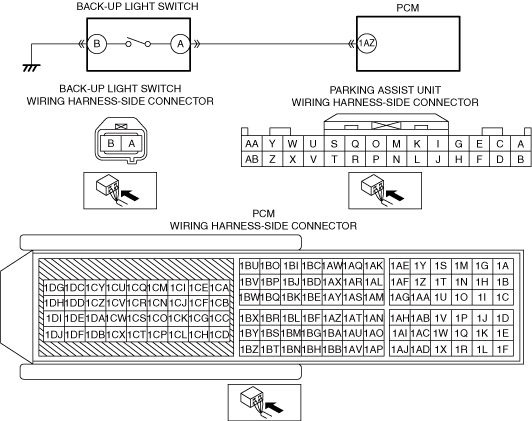

System Wiring Diagram

amxzzw00005692

|

Diagnostic Procedure

|

Step |

Inspection |

Action |

|

|---|---|---|---|

|

1

|

VERIFY MALFUNCTION SYMPTOM

• Verify that the warning is displayed in the multi-information display when the shift lever is in the reverse position (MTX) or the selector lever is in the R position (ATX).

• Is the warning displayed?

|

Yes

|

Perform an inspection referring to "WARNING IS DISPLAYED IN MULTI-INFORMATION DISPLAY WHEN SHIFT LEVER IS IN REVERSE POSITION (MTX) OR SELECTOR LEVER IS IN R POSITION (ATX)".

|

|

No

|

Go to the next step.

|

||

|

2

|

VERIFY ALL SYSTEM DTCs

• Switch the ignition off.

• Switch the ignition ON (engine off or on) and wait for 10 s or more.

• Perform a CMDTC self-test using the M-MDS.

• Are any DTCs displayed?

|

Yes

|

Repair or replace the malfunctioning part according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

||

|

3

|

VERIFY REAR BUMPER EXTERNAL APPEARANCE AND INSTALLATION CONDITION

• Verify that the rear bumper external appearance and installation condition.

• Are the rear bumper external appearance and installation condition normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the rear bumper.

(See REAR BUMPER REMOVAL.)

(See REAR BUMPER INSTALLATION.)

|

||

|

4

|

VERIFY IF SYSTEM IS PURSUANT TO INHIBIT/LIMIT CONDITIONS

• Perform the malfunction diagnosis for the inhibit/limit conditions and verify if the system is pursuant to the inhibit/limit conditions.

• Is there anything pursuant to the inhibit/limit conditions?

|

Yes

|

Perform malfunction diagnosis for inhibit/limit conditions.

|

|

No

|

Go to the next step.

|

||

|

5

|

INSPECT PARKING ASSIST UNIT CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the negative battery terminal.

• Disconnect the parking assist unit connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector.

|

||

|

6

|

VERIFY MALFUNCTION CONDITION

• Verify with the customer the malfunction condition.

• At the time of the malfunction, did the customer drive the vehicle under any of the following conditions?

|

Yes

|

System is normal. (Explain to the customer that the system does not operate on steep slopes or if the steering angle is too wide.)

|

|

No

|

Go to the next step.

|

||

|

7

|

DETERMINE MALFUNCTION CAUSE

• Using the M-MDS, display the following PIDs for the parking assist unit.

• Does the shift lever position (MTX) or selector lever position (ATX) switch correctly in conjunction with the indicator?

|

Yes

|

Go to Step 18.

|

|

No

|

ATX:

• Replace the TCM.

MTX:

• Go to the next step.

|

||

|

8

|

INSPECT BACK-UP LIGHT SWITCH CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the negative battery terminal.

• Disconnect the back-up light switch connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector.

|

||

|

9

|

INSPECT BACK-UP LIGHT SWITCH

• Inspect the back-up light switch.

• Is the back-up light switch normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the back-ip light switch.

|

||

|

10

|

INSPECT BACK-UP LIGHT SWITCH GROUND CIRCUIT FOR OPEN CIRCUIT

• Verify that the back-up light switch connector is disconnected.

• Inspect the wiring harness for continuity between back-up light switch terminal B (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between back-up light switch terminal B and body ground.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

|

||

|

11

|

INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector.

|

||

|

12

|

INSPECT BACK-UP LIGHT SWITCH CIRCUIT FOR SHORT TO GROUND

• Verify that the back-up light switch and PCM connectors are disconnected.

• Inspect for continuity between back-up light switch terminal A (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Back-up light switch terminal A—PCM terminal 1AZ

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

|

|

No

|

Go to the next step.

|

||

|

13

|

INSPECT BACK-UP LIGHT SWITCH CIRCUIT FOR SHORT TO POWER SUPPLY

• Verify that the back-up light switch and PCM connectors are disconnected.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off or on).

• Measure the voltage at the back-up light switch terminal A (wiring harness-side).

• Is the voltage 0 V?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Back-up light switch terminal A—PCM terminal 1AZ

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to power supply.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to power supply.

|

||

|

14

|

INSPECT BACK-UP LIGHT SWITCH CIRCUIT FOR OPEN CIRCUIT

• Switch the ignition off.

• Disconnect the negative battery terminal.

• Verify that the back-up light switch and PCM connectors are disconnected.

• Inspect the wiring harness for continuity between the following terminals (wiring harness-side).

• Is there continuity?

|

Yes

|

Replace the PCM.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Back-up light switch terminal A—PCM terminal 1AZ

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

|

||

|

15

|

INSPECT REAR ULTRASONIC SENSOR

• Inspect the rear ultrasonic sensor.

(See ULTRASONIC SENSOR INSPECTION.)

• Is the rear ultrasonic sensor normal?

|

Yes

|

System is normal. (Explain the operating conditions and non-operating conditions of the system to the customer.)

|

|

No

|

Replace the malfunctioning rear ultrasonic sensor.

|

||