|

1

|

RECORD SNAPSHOT DATA AND DIAGNOSTIC MONITORING TEST RESULTS TO UTILIZE WITH REPEATABILITY VERIFICATION

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

• Record the snapshot data and DIAGNOSTIC MONITORING TEST RESULTS (fuel system related) on the repair order.

|

—

|

Go to the next step.

|

|

2

|

VERIFY IF DIAGNOSTIC RESULT IS AFFECTED BY OTHER RELATED DTCs OCCURRING

• Using the M-MDS, perform the EVP control unit DTC inspection.

• Is any other DTC or pending code stored?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

|

3

|

DETERMINE IF VACUUM LINE MALFUNCTION

• Switch the ignition ON (engine off).

• Access the following EVP control unit PIDs using the M-MDS:

-

― VPR1_V

― VPR2_V

― VS1

― VS2

• Are VPR_1 and VPR_2 both ON, and are VS1 and VS2 both 23.3 kPa {175 mmHg, 6.89 inHg} or more on the snap shot data?

|

Yes

|

Inspect for leakage in vacuum line.

Repair or replace the malfunctioning part, then go to Step 8.

|

|

No

|

Go to the next step.

|

|

4

|

DETERMINE IF ELECTRIC VACUUM PUMP MALFUNCTION

• Switch the ignition ON (engine off).

• Access the following EVP control unit PIDs using the M-MDS:

-

― VP_MV

― VP_PV

― VP_C

• Verify PID value based on the service questions content and snap shot data driving conditions.

• Are PID values within specification?

Specification:

• When the electric vacuum pump is operated:

-

VP_MV: Below 0.8 V

VP_PV: 8.0—17.4 V

VP_C: 0—15 A

• When the electric vacuum pump is stopped:

-

VP_MV: 4.1—8.7 V

VP_PV: 4.1—8.7 V

VP_C: Approx. 0 A

|

Yes

|

Go to the next step.

|

|

No

|

Inspect for short to ground in the electric vacuum pump internal circuit.

If there is a malfunction in electric vacuum pump internal circuit:

• Replace the electric vacuum pump, then go to Step 8.

If there is not malfunction in electric vacuum pump internal circuit:

• Go to the next step.

|

|

5

|

INSPECT ELECTRIC VACUUM PUMP CIRCUIT FOR SHORT TO GROUND CIRCUIT

• Switch the ignition OFF.

• Disconnect the negative battery cable.

• Disconnect the electric vacuum pump connector.

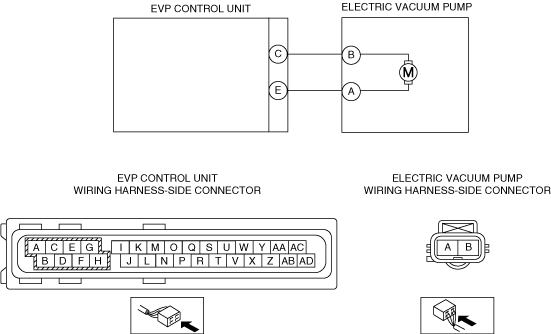

• Inspect for continuity between electric vacuum pump terminal A (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Disconnect the EVP control unit connector and inspect the wiring harness for short to ground.

• If the short to ground circuit could be detected in the wiring harness:

-

― Refer to the wiring diagram and verify whether or not there is a common connector between electric vacuum pump terminal A and EVP control unit terminal E.

If there is a common connector:

-

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

-

• Repair or replace the wiring harness which has a short to ground circuit.

• If the short to ground circuit could not be detected in the wiring harness:

-

― Replace the EVP control unit. (short to ground in the EVP control unit internal circuit)

Go to Step 8.

|

|

No

|

Go to the next step.

|

|

6

|

DRIVE VEHICLE THEN VERIFY DTC REPEATABILITY BASED ON SERVICE QUESTIONING RESULTS AND SNAP SHOT DATA

• Switch the ignition ON (engine off).

• Access the following EVP control unit PIDs using the M-MDS:

-

― VPS_FBK

― VP_MV

― VP_PV

― VP_C

― VPR1_V

― VPR2_V

― VS1

― VS2

• Verify PID value based on the service questions content and snap shot data driving conditions.

• Are PID values within specification?

-

Specification:

When the electric vacuum pump is operated (VPS_FBK PID value is On):

-

VP_MV: below 0.8 V

VP_PV: 8.0—17.4 V

VP_C: 0—15 A

VPR1_V, VPR2_V: On

VS1, VS2: below 40 kPa {300 mmHg, 11 inHg}

When the electric vacuum pump is stopped (VPS_FBK PID value is Off):

-

VP_MV: 4.1—8.7 V

VP_PV: 4.1—8.7 V

VP_C: Approx.0 A

VPR1_V, VPR2_V: Off

VS1, VS2: 23.3 kPa {175 mmHg, 6.89 inHg} or more

|

Yes

|

Go to the next step.

|

|

No

|

Inspect related components and harnesses.

Repair or replace the malfunctioning part, then go to Step 8.

|

|

7

|

VERIFY DTC REPEATABILITY AND DETERMINE IF MALFUNCTION CAUSE IS EVP CONTROL UNIT

• Using the M-MDS, clear the DTC from the EVP control unit.

• Switch the ignition ON (engine off).

• Using the M-MDS, perform the EVP control unit DTC inspection.

• Is the same DTC present?

|

Yes

|

Replace the EVP control unit, then go to Step 9.

|

|

No

|

DTC troubleshooting completed.

Explain to the customer that there are no malfunctions with the vehicle based on the contents of the servicing.

|

|

8

|

VERIFY DTC TROUBLESHOOTING COMPLETED

• Using the M-MDS, clear the DTC from the EVP control unit.

• Using the M-MDS, perform the EVP control unit DTC inspection.

• Is the same DTC present?

|

Yes

|

Repeat the inspection from Step1.

If the malfunction recurs, replace the EVP control unit, then go to the next step.

|

|

No

|

Go to the next step.

|

|

9

|

VERIFY NO DTC IS PRESENT

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|