|

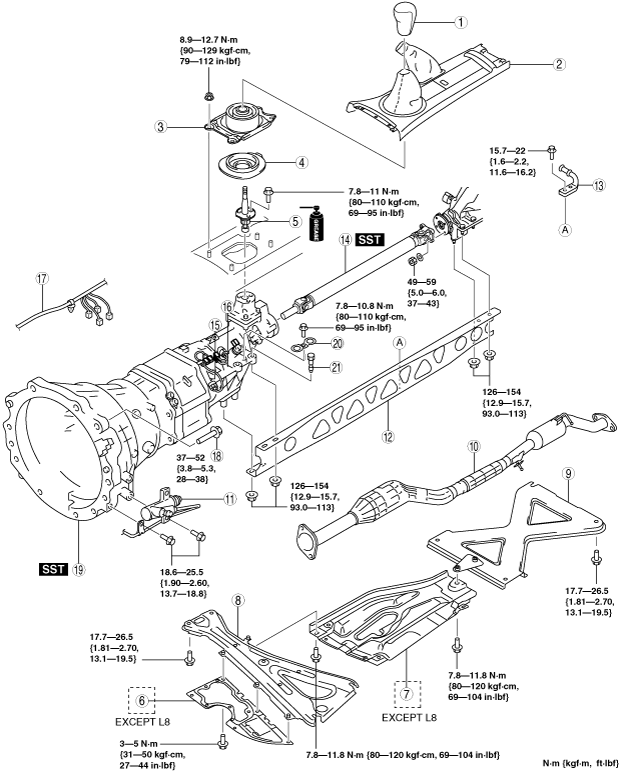

TRANSMISSION REMOVAL/INSTALLATION [M15M-D]

id051110246700

1. Remove the battery cover. (See BATTERY REMOVAL/INSTALLATION [L8, LF].)

2. Disconnect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION [L8, LF].)

3. Loosen the starter installation bolts only enough that the starter is loose, but not removed. (See STARTER REMOVAL/INSTALLATION [L8, LF].)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

6. Perform the "INSPECTION AFTER TRANSMISSION INSTALLATION", and verify that there is no malfunction. (See INSPECTION AFTER TRANSMISSION INSTALLATION [M15M-D].)

amxzzw00000480

|

|

1

|

Shift lever knob

|

|

2

|

Console

|

|

3

|

Shift insulator component (outer)

|

|

4

|

Shift insulator component (inner)

|

|

5

|

Shift lever component

|

|

6

|

Under guard

|

|

7

|

Insulator

|

|

8

|

Member bracket

|

|

9

|

Tunnel member

|

|

10

|

Catalytic converter, middle pipe

|

|

11

|

Clutch release cylinder

|

|

12

|

Power plant frame

|

|

13

|

Hanger bracket

|

|

14

|

Propeller shaft

(See Propeller Shaft Removal Note.)

|

|

15

|

Back-up light switch connector

|

|

16

|

Neutral switch connector

|

|

17

|

Wire

|

|

18

|

Transmission installation bolt

|

|

19

|

Transmission

|

|

20

|

Stopper

|

|

21

|

Bolt

|

Power Plant Frame Removal Note

1. Support the transmission using a transmission jack.

amxzzw00000481

|

2. Remove the power plant frame.

Propeller Shaft Removal Note

1. Install the SST to the main shaft.

amxzzw00000482

|

2. Insert a slab of wood behind the rear differential, and remove the propeller shaft.

amxzzw00000483

|

Transmission Removal Note

1. Support the transmission securely using a transmission jack.

amxzzw00000484

|

2. Remove the transmission installation bolts.

3. Remove the transmission.

Transmission Installation Note

1. Shift to any gear position.

2. Install the SST to the main shaft.

amxzzw00000482

|

3. Place the transmission on the transmission jack and raise it.

amxzzw00000484

|

4. Install the transmission.

5. Tighten the transmission installation bolts and nuts.

amxzzw00000485

|

Power Plant Frame Installation Note

1. Support the transmission using a transmission jack.

amxzzw00000481

|

2. Install the power plant frame.

3. Temporarily tighten the nuts 1, 2, 3 in order shown in the figure.

amxzzw00001927

|

4. Tighten nut 2 until the power plant frame is seated in the rear differential.

5. Temporarily tighten the nuts 4, 5 in order shown in the figure.

6. Install the catalytic converter, middle pipe and tunnel member.

7. Raise the front end of the power plant frame (transmission side) or the transmission with the transmission jack, and adjust dimension A to 26.7—34.7 mm {1.06—1.36 in} (lower surface of power plant frame-upper surface of the tunnel member) as shown in the figure.

amxzzw00000487

|

8. Tighten the power plant frame installation nuts.

amxzzw00001928

|

9. Verify that dimension A is within the specification with the transmission jack removed.

Shift Lever Component Installation Note

1. Add the specified type and amount of oil to the shift control case.

amxzzw00000490

|

2. Apply grease to the areas of the shift lever component as shown in the figure.

amxzzw00000491

|

3. Align the shift lever component notch with the shift control case pin and install the shift lever component.