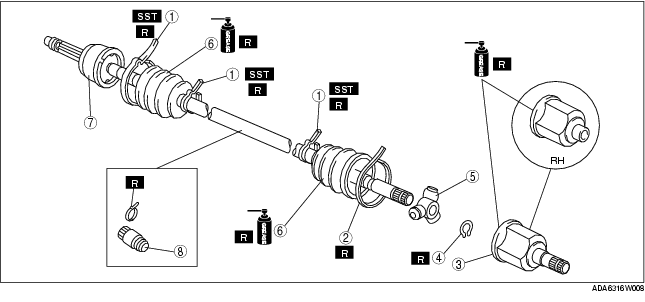

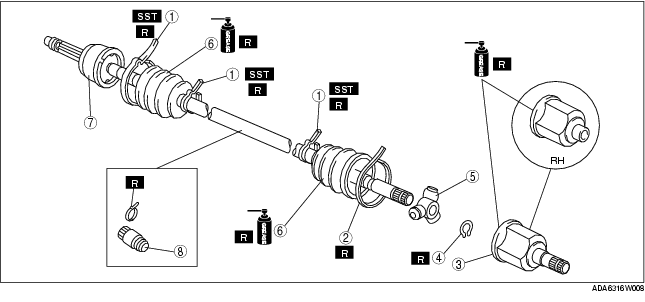

1. Disassemble in the order indicated in the table.

2. Assemble in the reverse order of disassembly.

|

1

|

Boot band (wheel side, transaxle side smaller diameter)

|

|

2

|

Boot band (transaxle side larger diameter)

|

|

3

|

Outer ring

(See Outer Ring Assembly Note)

|

|

4

|

Snap ring

|

|

5

|

Tripod joint

|

|

6

|

Boot

(See Boot Disassembly Note)

(See Boot Assembly Note)

|

|

7

|

Shaft and ball joint component

|

|

8

|

Dynamic damper

|

1. Remove the boot band using an end clamp plier.

1. Pry up the points indicated in the figure using a plier, and remove the boot band.

1. Mark the drive shaft and outer ring.

2. Remove the outer ring.

1. Mark the shaft and tripod joint.

2. Remove the snap ring using a snap ring plier.

3. Remove the tripod joint from the shaft.

1. Wrap the shaft splines with tape.

2. Remove the boot.

1. Install the dynamic damper as shown in the figure.

Length

2. Install a new boot band to the dynamic damper.

1. Fill the inside of the new dust boot (wheel side) with grease.

2. Install the boot with the splines of the shaft still wrapped in tape from disassembly.

3. Remove the tape.

1. Align the marks and insert the tripod joint using a bar and a hammer.

2. Insert a new snap ring using a snap ring plier.

1. Fill the outer ring and boot (transaxle side) with the specified grease.

2. Assemble the outer ring.

3. Set the drive shaft to the standard length.

Drive shaft length4. Release any trapped air from the boots by carefully lifting up the small end of each boot with a cloth wrapped screwdriver.

5. Verify that the drive shaft length is within the standard under atmospheric pressure inside the boot.

1. Pry up the points indicated in the figure using a plier, and tighten the boot band.

1. Adjust clearance A by turning the adjusting bolt of the SST.

Clearance A

2. Crimp the wheel side small boot band completely using the SST.

3. Verify that the boot band does not protrude from the boot band installation area.

4. Fill the boot with the repair kit grease.

5. Adjust clearance A by turning the adjusting bolt of the SST.

Clearance A6. Crimp the wheel side large boot band completely using the SST.

7. Verify that the boot band does not protrude from the boot band installation area.