CONNECTING ROD CLEARANCE INSPECTION

id011000507600

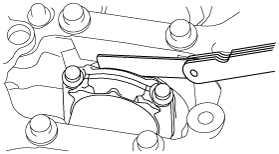

1. Measure the side clearance at the large end of the connecting rod using a feeler gauge.

-

• If it exceeds the maximum specification, replace the connecting rod or crankshaft.

-

Standard side clearance at the large end of connecting rod

-

0.14—0.36 mm {0.006—0.014 in}

-

Maximum side clearance at the large end of connecting rod

-

0.512 mm {0.0202 in}

2. Measure the oil clearance at the large end of the connecting rod using the following procedure:

- (1) Cut the plastigauge as wide as the connecting rod bearing width, place it parallel to the crankshaft, keeping away from the oil hole.

-

- (2) Install the lower connecting rod bearing and connecting rod cap. (See CYLINDER BLOCK ASSEMBLY (I).)

- (3) Remove the connecting rod cap. (See CYLINDER BLOCK DISASSEMBLY (II).)

- (4) Measure the oil clearance at the large end of the connecting rod.

-

-

• If it exceeds the maximum specification, replace the bearing or grind the crank pin and use oversize bearings so that the specified clearance is obtained.

-

Standard bearing oil clearance at the large end of the connecting rod

-

0.026—0.052 mm {0.0011—0.0020 in}

-

Maximum bearing oil clearance at the large end of the connecting rod

-

0.10 mm {0.00394 in}

-

Connecting rod bearing size

-

STD: 1.501—1.520 mm {0.05910—0.05984 in}

OS 0.25: 1.626—1.633 mm {0.06402—0.06429 in}

OS 0.50: 1.751—1.758 mm {0.06894—0.06921 in}