FUEL INJECTOR INSPECTION

id011400800700

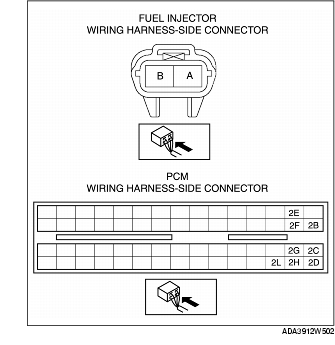

Resistance Inspection

1. Turn the ignition switch to the LOCK position.

2. Disconnect the negative battery cable.

3. Disconnect the fuel injector connector.

4. Inspect the resistance between fuel injector terminals A and B.

-

• If within the specification, carry out the "Circuit Open/Short Inspection".

-

• If not within the specification, replace the fuel injector.

Fuel injector resistance

-

Approx. 13.8 ohms [20°C {68 °F}]

Circuit Open/Short Inspection

1. Inspect the following wiring harnesses for an open or short circuit. (Continuity check)

Open circuit

-

• If there is no continuity, the circuit is open. Repair or replace the wiring harness.

-

- Fuel injector No.1 terminal A and PCM terminal 2E

-

- Fuel injector No.1 terminal B and PCM terminal 2B

-

- Fuel injector No.2 terminal A and PCM terminal 2F

-

- Fuel injector No.2 terminal B and PCM terminal 2C

-

- Fuel injector No.3 terminal A and PCM terminal 2G

-

- Fuel injector No.3 terminal B and PCM terminal 2D

-

- Fuel injector No.4 terminal A and PCM terminal 2L

-

- Fuel injector No.4 terminal B and PCM terminal 2H

Short circuit

-

• If there is continuity, the circuit is shorted. Repair or replace the wiring harness.

-

- Fuel injector terminal A and body GND

-

- Fuel injector terminal B and power supply

Leakage Inspection

-

Warning

-

• Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and damage. Fuel can also irritate skin and eyes. To prevent this, complete the following inspection with the engine stopped.

1. Complete the "BEFORE REPAIR PROCEDURE". (See BEFORE REPAIR PROCEDURE.)

2. Disconnect the negative battery cable.

3. Remove the fuel injector and fuel distributor as a single unit. (See FUEL INJECTOR REMOVAL/INSTALLATION.)

4. Fix the fuel injector to the fuel distributor with a wire or the equivalent.

5. Connect the fuel hose.

6. Connect the negative battery cable.

7. Remove the fuel pump relay.

-

Caution

-

• Short the specified terminal as shortening the wrong terminal of the main fuse block may cause a malfunction.

8. Using a jumper wire, short fuel pump relay terminals C and D and start the fuel pump.

9. Tilt the fuel injector at an angle of 60° to inspect leakage.

-

• If not within the specification, replace the fuel injector.

Fuel injector leakage amount

-

Less than 1 drop/2 min

10. Turn the ignition switch to the LOCK position and disconnect the jumper wire.

11. Complete the "AFTER REPAIR PROCEDURE". (See AFTER REPAIR PROCEDURE.)

Injection Volume Inspection

-

Warning

-

• Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and damage. To prevent this, complete the following inspection with the engine stopped.

1. Complete the "BEFORE REPAIR PROCEDURE". (See BEFORE REPAIR PROCEDURE.)

2. Disconnect the negative battery cable.

3. Remove the fuel injector and fuel distributor as a single unit. (See FUEL INJECTOR REMOVAL/INSTALLATION.)

4. Fix the fuel injector to the fuel distributor with a wire or the equivalent.

5. Connect the SST to the corresponding fuel injector and battery.

6. Connect the negative battery cable.

7. Remove the fuel pump relay.

-

Caution

-

• Short the specified terminal as shortening the wrong terminal of the main fuse block may cause a malfunction.

8. Using a jumper wire, short fuel pump relay terminals C and D and start the fuel pump.

9. Measure the fuel injection volume.

-

• If not within the specification, replace the fuel injector.

Fuel injection volume

-

Approx. 235 ml {235cc, 14 cu in}/min

10. Turn the ignition switch to the LOCK position and disconnect the jumper wire.

11. Complete the "AFTER REPAIR PROCEDURE". (See AFTER REPAIR PROCEDURE.)

Atomization Inspection

1. Inspect the atomization status.

-

• If there is any irregularity, replace the fuel injector.