FUEL PUMP UNIT INSPECTION

id011400801100

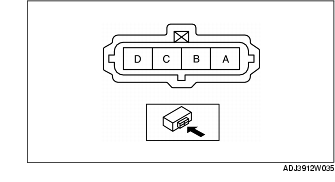

Continuity Inspection

1. Disconnect the negative battery cable.

2. Disconnect the fuel pump unit connector.

3. Inspect for continuity between fuel pump unit connector terminals B and D.

-

• If there is continuity, carry out the "Circuit Open/Short Inspection".

-

• If there is no continuity, replace the fuel pump.

Circuit Open/Short Inspection

1. Inspect the following wiring harnesses for an open or short circuit. (Continuity check)

Open circuit

-

• If there is no continuity, the circuit is open. Repair or replace the wiring harness.

-

- Fuel pump unit terminal B and fuel pump relay terminal C

-

- Fuel pump unit terminal D and body GND

Short circuit

-

• If there is continuity, the circuit is shorted. Repair or replace the wiring harness.

-

- Fuel pump unit terminal B and body GND

-

- Fuel pump unit terminal D and power supply

Fuel Static Pressure Inspection

-

Warning

-

• Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and damage. To prevent this, complete the following inspection with the engine stopped.

1. Complete the "BEFORE REPAIR PROCEDURE". (See BEFORE REPAIR PROCEDURE.)

2. Disconnect the negative battery cable.

3. Perform the following procedure for easier access.

-

(1) Disconnect the PCM connector, MAF sensor connector, and IAT sensor connector.

-

(2) Remove the air cleaner cover.

-

(3) Disconnect the HO2S sensor connector.

-

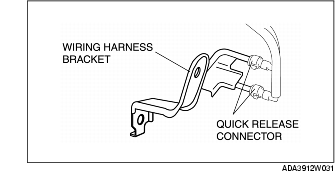

(4) Set the wiring harness bracket out of the way.

4. Disconnect the quick release connector. (See FUEL HOSE (ENGINE ROOM SIDE) REMOVAL/INSTALLATION.)

5. Turn the SST lever so that it is 90° to the hose as shown in the figure.

6. Insert the SST quick release connector into the fuel pipe until a click is heard.

7. Verify that the quick release connector is firmly connected by pulling it by hand.

8. Connect the negative battery cable.

9. Remove the fuel pump relay.

-

Caution

-

• Short the specified terminal as shortening the wrong terminal of the main fuse block may cause malfunctions.

10. Using a jumper wire, short fuel pump relay terminals C and D and start the fuel pump.

11. Measure the fuel static pressure.

-

• If not within the specification, inspect for the following and then if there is no malfunction replace the fuel pump.

-

- Fuel line leakage

-

- Fuel filter clogging (high-pressure side and low-pressure side)

-

- Fuel line clogging

Fuel static pressure

-

500-850 kPa {5.1-8.6 kgf/cm2, 73-120 psi}

12. Disconnect the SST.

13. Connect the quick release connector. (See FUEL HOSE (ENGINE ROOM SIDE) REMOVAL/INSTALLATION.)

14. Complete the "AFTER REPAIR PROCEDURE". (See AFTER REPAIR PROCEDURE.)