|

am2zzw00005283

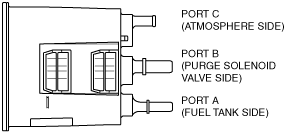

CHARCOAL CANISTER INSPECTION [MZR 1.3, MZR 1.5]

id011606800500

Leakage Inspection

1. Remove the charcoal canister. (See CHARCOAL CANISTER REMOVAL/INSTALLATION [MZR 1.3, MZR 1.5].)

2. Perform the following procedure:

am2zzw00005283

|

3. Apply pressure (19.6 kPa {0.20 kgf/cm2, 2.84 psi}) through the hose, and verify that air does not leak from the charcoal canister.

am2zzw00005284

|

Airflow Inspection

1. Remove the charcoal canister. (See CHARCOAL CANISTER REMOVAL/INSTALLATION [MZR 1.3, MZR 1.5].)

2. Perform the following procedure to verify the charcoal canister airflow.

am2zzw00005285

|

am2zzw00005286

|

am2zzw00005287

|