|

1

|

INSPECT BRAKE FLUID AMOUNT AND VERIFY THAT ELECTRIC PARKING BRAKE RELEASED

• Inspect the brake fluid amount and verify that the electric parking brake released.

• Is the brake fluid amount normal?

• Is the electric parking brake released?

|

Yes

|

Go to the next step.

|

|

No

|

Add the brake fluid or release the electric parking brake.

If the brake fluid refilled:

• Inspect and repair the brake line for leakage.

Perform the repair completion verification.

|

|

2

|

CONFIRM ELECTRONICALLY CONTROLLED BRAKE UNIT DTC

• Retrieve the electronically controlled brake unit DTC using the M-MDS.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

If communication error message is displayed on the M-MDS screen:

• Go to the next step.

If communication error message is not displayed:

• Go to Step 4.

|

|

3

|

INSPECT CONNECTION OF ELECTRONICALLY CONTROLLED BRAKE UNIT CONNECTOR

• Inspect for connection of the electronically controlled brake unit connector.

• Is the electronically controlled brake unit connector connected securely?

|

Yes

|

Go to the next step.

|

|

No

|

Connect the electronically controlled brake unit connector securely, then go to the next step.

|

|

4

|

CONFIRM INSTRUMENT CLUSTER OPERATION RECORD

• Retrieve the warning system operation history using the M-MDS.

• Is the brake system warning light illumination history recorded?

|

Yes

|

If the Brake Waning Lamp recorded:

• Go to Step 5.

If the Brake Waning Lamp (Brake fluid low) recorded:

• Go to Step 6.

|

|

No

|

Go to Step 8.

|

|

5

|

VERIFY WHETHER MALFUNCTION IS IN INSTRUMENT CLUSTER OR ELSEWHERE

• Connect the M-MDS to the DLC-2.

• Ignition is switched ON (engine off).

• Do the ABS warning light, brake system warning light, DSC indicator light and DSC OFF indicator light turn on and off according to the simulation?

|

Yes

|

Go to Step 8.

|

|

No

|

Replace the instrument cluster, and perform the repair completion verification.

|

|

6

|

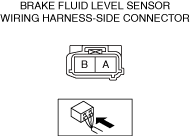

INSPECT WHETHER MALFUNCTION IS IN BRAKE FLUID LEVEL SENSOR OR ELSEWHERE

• Inspect the brake fluid level sensor.

• Is the continuity condition normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the malfunctioning part, and perform the repair completion verification.

|

|

*7

|

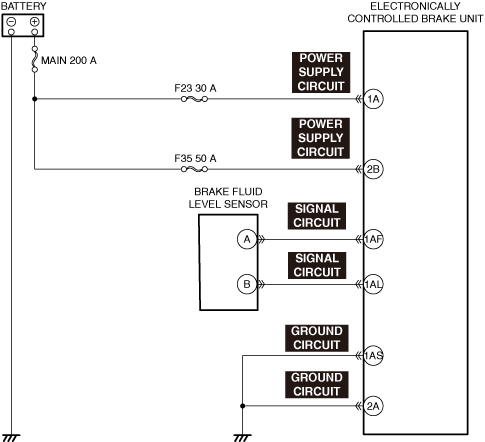

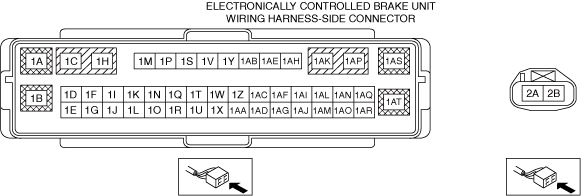

INSPECT BRAKE FLUID LEVEL SENSOR SIGNAL CIRCUIT FOR SHORT TO GROUND

• Inspect the signal circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Retrieve the electronically controlled brake unit DTC using the M-MDS.

If the DTC remains:

• Go to the applicable DTC inspection.

If the DTC does not remain:

• Replace the electronically controlled brake unit.

|

|

No

|

Repair or replace the malfunctioning location, and perform the repair completion verification.

|

|

*8

|

INSPECT ELECTRONICALLY CONTROLLED BRAKE UNIT POWER SUPPLY CIRCUIT FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the power supply circuit for an open circuit and short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location, and perform the repair completion verification.

|

|

*9

|

INSPECT ELECTRONICALLY CONTROLLED BRAKE UNIT GROUND CIRCUIT FOR SHORT TO POWER SUPPLY AND OPEN CIRCUIT

• Inspect the ground circuit for an open circuit and short to power supply.

• Is the circuit normal?

|

Yes

|

Replace the electronically controlled brake unit, and perform the repair completion verification. (open circuit in the electronically controlled brake unit)

|

|

No

|

Repair or replace the malfunctioning location, and perform the repair completion verification.

|

|

Repair completion verification

|

VERIFY THAT MALFUNCTION SYMPTOMS DO NOT RECUR AFTER REPAIR

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting.

Explain to the customer what has been repaired.

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

|