|

1

|

INSPECT EFFECT OF NON-GENUINE ELECTRICAL ACCESSORY FOR CAUSE OF MALFUNCTION

• Remove any non-genuine electrical accessory.

• Verify the malfunction symptom.

• Is the frequency of the engine restarting from the i-stop off condition the same as that of another vehicle of the same model?

|

Yes

|

The system is normal.

• Explain to the customer that the frequency of the engine restarting increases due to the effect of the non-genuine electrical accessory installed.

|

|

No

|

Go to the next step.

|

|

2

|

VERIFY DTC

• Perform the DTC inspection for the following modules.

-

― PCM

― TCM (ATX)

― DSC HU/CM

― Dash-electrical supply unit

― Body control module (BCM)

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT BATTERY FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

4

|

INSPECT GENERATOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

5

|

DETERMINE IF MALFUNCTION CAUSE IS STEERING ANGLE SENSOR SIGNAL OR OTHER

• Start the engine and let it idle.

• Access the EPS control module PID STR_ANG using the M-MDS.

• Is the PID value normal?

|

Yes

|

Go to Step 8.

|

|

No

|

Go to the next step.

|

|

6

|

INSPECT STEERING ANGLE SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

7

|

INSPECT EPS CONTROL MODULE FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Perform the following procedure:

1. Switch the ignition off, and after 2 min or more have elapsed, switch the ignition ON.

2. Start the engine and drive the vehicle 10 m {32 ft 10 in} or more in a straight line at a speed of 10 km/h {6.2 mph} or more.

3. Stop the vehicle with the wheels in the straight-ahead position.

4. Access the EPS control module PID STR_ANG using the M-MDS.

-

• If the STR_ANG value is normal, perform the repair completion verification 1. (Because the steering angle (estimated absolute angle) has returned to normal)

• If the STR_ANG value is not normal, replace the EPS control module, then perform the repair completion verification 1.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

8

|

DETERMINE IF MALFUNCTION CAUSE IS POWER BRAKE UNIT VACUUM SENSOR SIGNAL OR OTHER

• Put the vehicle in an i-stop condition (engine stopped).

• Access the PCM PID BRK_BSTR_PRES_ACT using the M-MDS with the brake pedal depressed and the engine stopped.

• Does the BRK_BSTR_PRES_ACT PID value remain less than -45 kPa {-0.46 kgf/cm2, -6.5 psi}?

|

Yes

|

Go to Step 12.

|

|

No

|

Go to the next step.

|

|

9

|

INSPECT POWER BRAKE UNIT VACUUM SENSOR FOR AIR TIGHTNESS MALFUNCTION

• Perform the vacuum function inspection for the power brake unit and the vacuum loss inspection.

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

No

|

Go to the next step.

|

|

10

|

INSPECT POWER BRAKE UNIT VACUUM SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

11

|

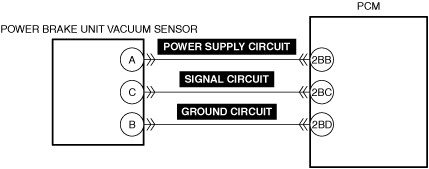

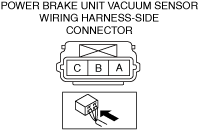

INSPECT POWER BRAKE UNIT VACUUM SENSOR POWER SUPPLY CIRCUIT, SIGNAL CIRCUIT, AND GROUND CIRCUIT FOR SHORT CIRCUIT AND OPEN CIRCUIT

• Inspect the applicable circuit for a short circuit and open circuit.

• Is the circuit normal?

|

Yes

|

Perform the repair completion verification 1.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

12

|

INSPECT DRIVER-SIDE AIR MIX ACTUATOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Inspect the air mix door and linkage for sticking.

If there is no malfunction:

• Go to the next step.

If there is any malfunction:

• Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

13

|

DETERMINE IF MALFUNCTION CAUSE IS BRAKE FLUID PRESSURE SENSOR SIGNAL OR OTHER

• Put the vehicle in an i-stop condition (engine stopped).

• Monitor the DSC HU/CM PID BRK_FLD_PRES using the M-MDS while the brake is depressed and held with the i-stop function operating.

• Does the monitoring value change?

|

Yes

|

ATX:

• Perform the repair completion verification 1.

MTX:

• Go to the next step.

|

|

No

|

Brake fluid pressure sensor malfunction.

• Replace the DSC HU/CM, then perform the repair completion verification 1.

|

|

14*

|

DETERMINE IF MALFUNCTION CAUSE IS CLUTCH STROKE SENSOR SIGNAL OR OTHER

• Switch the ignition ON (engine off).

• Access the PCM PID CLTCH_PEDAL_POS using the M-MDS.

• Does the CLTCH_PEDAL_POS PID value change according to the amount the clutch pedal is depressed?

|

Yes

|

Perform the repair completion verification 1.

|

|

No

|

Go to the next step.

|

|

15

|

INSPECT CLUTCH STROKE SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

16

|

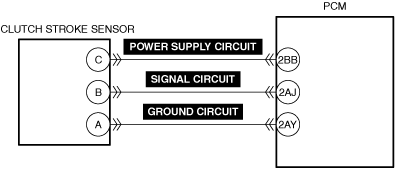

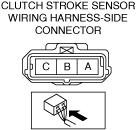

INSPECT CLUTCH STROKE SENSOR SIGNAL CIRCUIT FOR SHORT TO POWER SUPPLY

• Inspect the applicable circuit for a short to power supply.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification 1.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting. (Explain contents of repair to customer)

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, perform the diagnosis from Step 1.

-

― If the malfunction recurs, go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF MALFUNCTION IS CAUSED BY NOT PERFORMING PCM REPROGRAMMING

• Verify repair information and verify that there is a new calibration in the PCM.

• Is there a new calibration in the PCM?

|

Yes

|

Perform the PCM reprogramming and verify if the malfunction symptom was corrected.

• If the malfunction recurs, replace the PCM.

|

|

No

|

Replace the PCM.

|