DTC P1A1C:00

Power relay and/or power drive relay performance problem

DETECTION CONDITION

• The PCM calculates the number of times the power relay and power drive relay operation and records the value in the built-in non-volatile ROM. The PCM records DTCs when the number of times the power relay and power drive relay has been operated reaches the warrantied performance frequency for the power relay and power drive relay.

• Detects DTC if any of the following conditions are met:

-

― The average of the electric potential difference between the main battery and the sub-battery is 3 V or more while the power relay/power drive relay is commanded on when the engine is started using the IG key.― The charge/discharge flow of the sub-battery exceeds 3 A for a continuous 3 s or more with the charge relay, power relay, and power drive relay in the off condition after starting the engine.― The electric potential difference between the main battery and the sub-battery is 0.2 V or less with the charge relay, power relay, and power drive relay in the off condition after starting the engine.

Diagnostic support note

• This is a continuous monitor (other).

• The MIL does not illuminate.

• FREEZE FRAME DATA (Mode 2)/Snapshot data is not available.

• The DTC is stored in the PCM memory.

POSSIBLE CAUSE

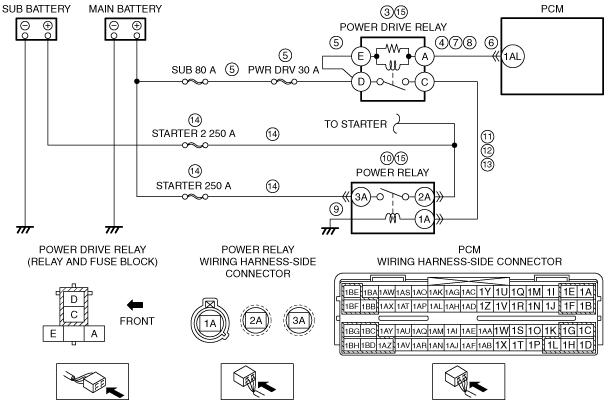

• Power drive relay malfunction

• Short to ground in wiring harness between power drive relay terminal A and PCM terminal 1AL

• Short to ground or open circuit in power drive relay power supply circuit

-

― Short to ground in wiring harness between main battery positive terminal and power drive relay terminal E― Short to ground in wiring harness between main battery positive terminal and power drive relay terminal D― PWR DRV 30 A fuse malfunction― Open circuit in wiring harness between main battery positive terminal and power drive relay terminal E― Open circuit in wiring harness between main battery positive terminal and power drive relay terminal D

• PCM connector or terminals malfunction

• Open circuit in wiring harness between power drive relay terminal A and PCM terminal 1AL

• Short to power supply in wiring harness between power drive relay terminal A and PCM terminal 1AL

• Open circuit in power relay ground

• Power relay malfunction

• Short to ground in wiring harness between power drive relay terminal C and power relay terminal 1A

• Short to power supply in wiring harness between power drive relay terminal C and power relay terminal 1A

• Open circuit in wiring harness between power drive relay terminal C and power relay terminal 1A

• Short to ground or open circuit in power relay circuit

-

― Short to ground in wiring harness between main battery positive terminal and power relay terminal 3A― Short to ground in wiring harness between sub battery positive terminal and power relay terminal 2A― STARTER 250 A fuse malfunction― STARTER 2 250 A fuse malfunction― Open circuit in wiring harness between main battery positive terminal and power relay terminal 3A― Open circuit in wiring harness between sub battery positive terminal and power relay terminal 2A

• Number of times power relay and power drive relay has been operated has reached warrantied performance frequency for power relay and power drive relay.

• PCM malfunction