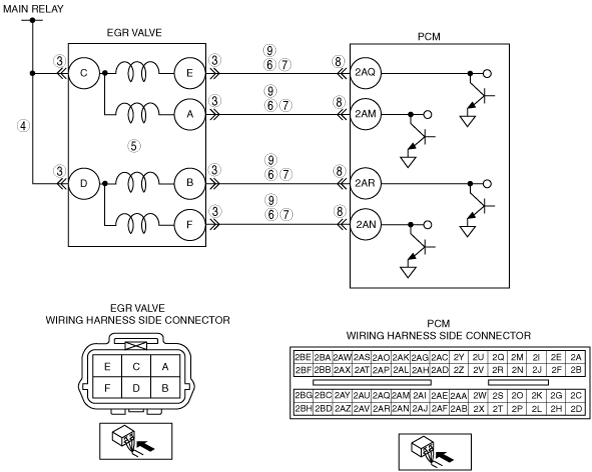

DTC P0403

EGR valve (stepper motor) circuit malfunction

DETECTION CONDITION

• PCM monitors the input voltage from the EGR valve. If the voltage remain low or high, the PCM determines that the EGR valve circuit has a malfunction.

Diagnostic support note

• This is a continuous monitor (CCM).

• MIL illuminates if the PCM detects above malfunction condition in two consecutive drive cycles or in one drive cycle while the DTC for the same malfunction has been stored in the PCM.

• PENDING CODE is available if the PCM detects the above malfunction condition during first drive cycle.

• FREEZE FRAME DATA is not available.

• DTCs are not stored in the PCM memory.

POSSIBLE CAUSE

• EGR valve malfunction

• Connector or terminal malfunction

• Short to the power supply in the wiring harness between EGR valve terminal E and PCM terminal 2AQ

• Short to the power supply in the wiring harness between EGR valve terminal A and PCM terminal 2AM

• Short to the power supply in the wiring harness between EGR valve terminal B and PCM terminal 2AR

• Short to the power supply in the wiring harness between EGR valve terminal F and PCM terminal 2AN

• Short to ground circuit in wiring harness between EGR valve terminal E and PCM terminal 2AQ

• Short to ground circuit in wiring harness between EGR valve terminal A and PCM terminal 2AM

• Short to ground circuit in wiring harness between EGR valve terminal B and PCM terminal 2AR

• Short to ground circuit in wiring harness between EGR valve terminal F and PCM terminal 2AN

• Open circuit in the wiring harness between EGR valve terminal E and PCM terminal 2AQ

• Open circuit in the wiring harness between EGR valve terminal A and PCM terminal 2AM

• Open circuit in the wiring harness between EGR valve terminal B and PCM terminal 2AR

• Open circuit in the wiring harness between EGR valve terminal F and PCM terminal 2AN

• Open circuit in the wiring harness between main relay and EGR valve terminal C

• Open circuit in the wiring harness between main relay and EGR valve terminal D

• PCM malfunction