|

OIL PUMP REMOVAL/INSTALLATION [LF, L3]

id0111b5800600

1. Remove the battery cover. (See BATTERY REMOVAL/INSTALLATION[LF, L3].)

2. Disconnect the negative battery cable.

3. Remove the under cover and splash shield as a single unit.

4. Remove the front tire (RH).

5. Drain the engine oil. (See ENGINE OIL REPLACEMENT[LF, L3].)

6. Remove the plug hole plate. (See PLUG HOLE PLATE REMOVAL/INSTALLATION[LF, L3].)

7. Remove the drive belt. (See DRIVE BELT REPLACEMENT[LF, L3].)

8. Position the coolant reserve tank out of the way.

9. Remove the A/C compressor with the pipes still connected. (See A/C COMPRESSOR REMOVAL/INSTALLATION[LF, L3].)

10. Remove the ignition coils. (See IGNITION COIL REMOVAL/INSTALLATION[LF, L3].)

11. Remove the crankshaft position (CKP) sensor. (See CRANKSHAFT POSITION (CKP) SENSOR REMOVAL/INSTALLATION[LF, L3].)

12. Remove the engine front cover. (See TIMING CHAIN REMOVAL/INSTALLATION[LF, L3].)

13. Remove the oil pan. (See OIL PAN REMOVAL/INSTALLATION[LF, L3].)

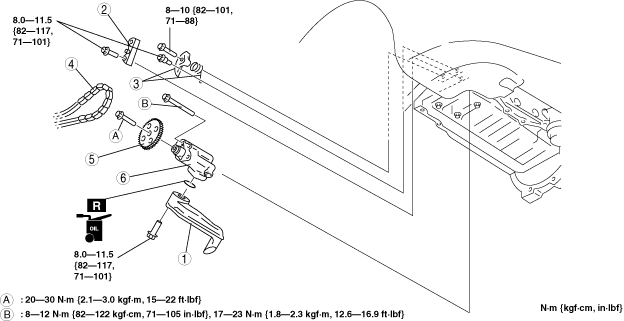

14. Remove in the order indicated in the table.

15. Install in the reverse order of removal.

16. Refill with the specified type and amount of the engine oil. (See ENGINE OIL REPLACEMENT[LF, L3].)

17. Start the engine and confirm that there is no oil leakage.

18. Inspect the oil level. (See ENGINE OIL LEVEL INSPECTION[LF, L3].)

19. Inspect for the ignition timing and idle speed. (See ENGINE TUNE-UP[LF, L3].)

am3zzw00021092

|

|

1

|

Oil strainer

|

|

2

|

Oil pump chain guide

|

|

3

|

Oil pump chain tensioner

|

|

4

|

Oil pump chain

|

|

5

|

Oil pump sprocket

|

|

6

|

Oil pump

(See Oil Pump Installation Note.)

|

Oil Pump Sprocket Removal/Installation Note

1. Temporarily install the crankshaft pulley and crankshaft pulley lock bolt to the crankshaft, and lock the oil pump against rotation as shown in figure.

am3zzw00004324

|

2. Remove/install the oil pump sprocket, and then remove the crankshaft pulley and crankshaft pulley lock bolt.

Oil Pump Installation Note

1. Tighten the oil pump bolts in two steps in the order shown in the figure.

am3zzw00002497

|