|

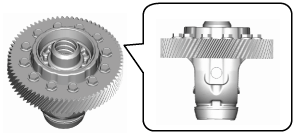

RING GEAR AND DIFFERENTIAL INSPECTION [EW6A-EL/EW6AX-EL]

id0517006624l4

Taper Roller Bearing Inspection

1. Place the ring gear and differential with the ring gear side pointing upward on a workbench.

bfw2za00000112

|

2. Assemble the taper roller bearing to the ring gear and differential.

bfw2za00000113

|

bfw2za00000114

|

3. With a load applied by hand to the taper roller bearing, rotate the taper roller bearing and verify that there is no malfunction in the taper roller bearing (rotation sticking).

bfw2za00000115

|

4. Remove the bearing race.

bfw2za00000116

|

5. Place the ring gear and differential with the ring gear side pointing downward on a workbench.

bfw2za00000117

|

6. Assemble the bearing race to the ring gear and differential.

bfw2za00000118

|

bfw2za00000119

|

7. With a load applied by hand to the bearing race, rotate the bearing race and verify that there is no malfunction in the taper roller bearing (rotation sticking).

bfw2za00000120

|

8. Remove the bearing race.

bfw2za00000121

|

Differential Journal Inspection

1. Measure the inner diameter of the journal (front side) shown in the figure.

bfw2za00000220

|

2. Measure the inner diameter of the journal (rear side) shown in the figure.

bfw2za00000123

|

Differential Backlash Inspection

1. Perform the following the inspection and measurement/adjustment in the order and replace a malfunctioning part with a new one.