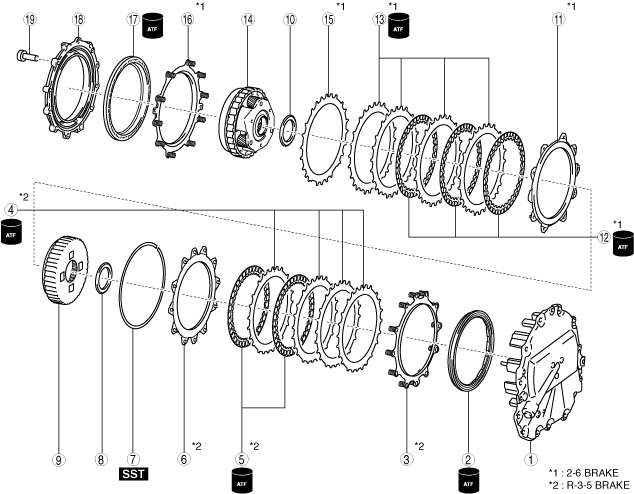

END COVER COMPONENT ASSEMBLY [FW6A-EL/FW6AX-EL]

id0517006642z3

Structural View (SKYACTIV-G 1.5)

|

1

|

End cover

|

|

2

|

R-3-5 brake piston

|

|

3

|

Springs and retainer component (inner diameter approx. 148.8 mm {5.858 in})

|

|

4

|

Driven plate (inner diameter approx. 141.8 mm {5.583 in})

|

|

5

|

Drive plate (outer diameter approx. 169.4 mm {6.669 in})

|

|

6

|

Retaining plate (inner diameter approx. 141.8 mm {5.583 in})

|

|

7

|

Snap ring (outer diameter approx. 186.2 mm {7.331 in}) (selection)

|

|

8

|

Thrust needle bearing (outer diameter approx. 63 mm {2.5 in})

|

|

9

|

Reduction internal gear

|

|

10

|

Thrust needle bearing (outer diameter approx. 63 mm {2.5 in})

|

|

11

|

Retaining plate (inner diameter approx. 148 mm {5.83 in})

|

|

12

|

Drive plate (outer diameter approx. 171.9 mm {6.768 in})

|

|

13

|

Driven plate (outer diameter approx. 148 mm {5.83 in}, thickness approx. 1.6 mm {0.063 in})

|

|

14

|

Reduction planetary gear

|

|

15

|

Retaining plate (inner diameter approx.148 mm {5.83 in}) (selection)

|

|

16

|

Springs and retainer component (inner diameter approx. 150.6 mm {5.929 in})

|

|

17

|

2-6 brake piston

|

|

18

|

Brake housing

|

|

19

|

8 bolts (M6×1.0 bolt, length to approx. 25 mm {0.98 in})

|

Structural View (SKYACTIV-G 2.0, SKYACTIV-G 2.5)

|

1

|

End cover

|

|

2

|

R-3-5 brake piston

|

|

3

|

Springs and retainer component (inner diameter approx. 148.8 mm {5.858 in})

|

|

4

|

Driven plate (inner diameter approx. 141.8 mm {5.583 in})

|

|

5

|

Drive plate (outer diameter approx. 169.4 mm {6.669 in})

|

|

6

|

Retaining plate (inner diameter approx. 141.8 mm {5.583 in})

|

|

7

|

Snap ring (outer diameter approx. 186.2 mm {7.331 in}) (selection)

|

|

8

|

Thrust needle bearing (outer diameter approx. 63 mm {2.5 in})

|

|

9

|

Reduction internal gear

|

|

10

|

Thrust needle bearing (outer diameter approx. 63 mm {2.5 in})

|

|

11

|

Retaining plate (inner diameter approx. 148 mm {5.83 in})

|

|

12

|

Drive plate (outer diameter approx. 171.9 mm {6.768 in})

|

|

13

|

Driven plate (outer diameter approx. 148 mm {5.83 in}, thickness approx. 1.6 mm {0.063 in})

|

|

14

|

Reduction planetary gear

|

|

15

|

Retaining plate (inner diameter approx.148 mm {5.83 in}) (selection)

|

|

16

|

Springs and retainer component (inner diameter approx. 150.6 mm {5.929 in})

|

|

17

|

2-6 brake piston

|

|

18

|

Brake housing

|

|

19

|

8 bolts (M6×1.0 bolt, length to approx. 25 mm {0.98 in})

|

Assembly Procedure

1. Assemble the R-3-5 brake piston using the following procedure:

- (1) Apply ATF (ATF FZ) to the R-3-5 brake piston lip.

-

- (2) Assemble the R-3-5 brake piston.

-

2. Measure the R-3-5 brake clearance and select the appropriate snap ring. (See R-3-5 BRAKE CLEARANCE MEASUREMENT/ADJUSTMENT.)

3. Assemble the springs and retainer component.

-

Note

-

• Springs and retainer component size: Inner diameter approx. 148.8 mm {5.858 in}

4. Assemble the drive plates and driven plates using the following procedure:

-

Note

-

• Drive plate size: Outer diameter approx. 169.4 mm {6.669 in}

• Driven plate size: Inner diameter approx. 141.8 mm {5.583 in}

- (1) Apply ATF (ATF FZ) to the drive plates and driven plates.

-

-

Caution

-

• If the drive plate is replaced with a new one, immerse it in ATF (ATF FZ) for 2 hours or more to permeate the facing with ATF.

- (2) Assemble the drive plates and driven plates. (SKYACTIV-G 1.5)

-

-

Assembly order

-

Driven plate—driven plate—driven plate—drive plate—driven plate—drive plate

A :Drive plate

B :Driven plate

- (3) Assemble the drive plates and driven plates. (SKYACTIV-G 2.0, SKYACTIV-G 2.5)

-

-

Assembly order

-

Driven plate—drive plate—driven plate—drive plate—driven plate—drive plate

A :Drive plate

B :Driven plate

5. Assemble the retaining plate.

-

Note

-

• Retaining plate size: Inner diameter approx. 141.8 mm {5.583 in}

6. Assemble the snap ring using the following procedure:

-

Note

-

• Snap ring size: Outer diameter approx. 186.2 mm {7.331 in}

- (1) Set the snap ring selected in Step 2 on top of the end cover.

-

A :Selection

- (2) Install the SST.

-

- (3) Set the SST and part to the press as shown in the figure.

-

-

Caution

-

• Using the rubber plates, adjust the alignment surface of the end cover with the transaxle case so that it is level. Otherwise the parts could tip over during the procedure and get damaged.

A :Press

B :Rubber plate

- (4) Press down the SST using the press until the snap ring groove of the end cover comes out.

-

-

Caution

-

• If the SST is pressed excessively by the press, surrounding parts could be damaged. Stop pressing down the SST using the press when the snap ring groove of the end cover comes out.

A :Snap ring groove

- (5) Assemble the snap ring to the position shown in the figure.

-

-

Caution

-

• Assemble the snap ring so that the end gap of the snap ring is in the area shown in the figure.

• After assembling the snap ring, verify that the snap ring is securely inserted into the bottom of the snap ring groove.

A :End gap of snap ring assembly area

- (6) Take the SST and part off the press.

-

- (7) Remove the SST.

-

7. Perform an operation verification of the R-3-5 brake using the following procedure:

- (1) Blow compressed air into the oil passage shown in the figure and verify the operation condition of the R-3-5 brake.

-

-

Warning

-

• Always wear protective eye wear when using the air compressor. Otherwise, ATF or dirt particles blown off by the air compressor could get into the eyes.

-

Caution

-

• To prevent damage to parts, always use an air compressor which is adjusted to the indicated pressure.

-

Compressed air pressure

-

0.39—0.44 MPa {4.0—4.4 kgf/cm2, 57—63 psi}

-

8. Assemble the thrust needle bearing.

-

Note

-

• Thrust needle bearing size: Outer diameter approx. 63 mm {2.5 in}

9. Assemble the reduction internal gear.

-

Note

-

• While rotating the reduction internal gear, engage the splines of each of the R-3-5 brake drive plates one by one, and assemble.

10. To verify that the reduction internal gear is securely assembled, measure the distance shown in the figure.

-

Note

-

• Recommended measuring instrument: Depth gauge, straight edge ruler

A :End cover end (alignment surface with brake housing)

B :Reduction internal gear end

-

Specification

-

45.0—46.1 mm {1.78—1.81 in}

-

• If not within the specification, remove the reduction internal gear and reassemble.

-

Note

-

- (1) Set two straight edge rulers along the alignment surfaces of the end cover with the brake housing as shown in the figure.

-

- (2) Measure the positions (2 locations) shown in the figure using a depth gauge and calculate the average value.

-

A :Straight edge ruler

- (3) Subtract the thickness of the straight edge ruler from the average value.

-

11. Assemble the thrust needle bearing.

-

Note

-

• Thrust needle bearing size: Outer diameter approx. 63 mm {2.5 in}

12. Assemble the retaining plate.

-

Note

-

• Retaining plate size: Inner diameter approx. 148 mm {5.83 in}

13. Assemble the drive plates and driven plates using the following procedure:

-

Caution

-

• The driven plate has a similar shape to the retaining plate used for the 2-6 brake clearance adjustment. Before assembling the driven plate, always verify the plate thickness and the shape.

-

Note

-

• Drive plate size: Outer diameter approx. 171.9 mm {6.768 in}

• Driven plate size: Inner diameter approx. 148 mm {5.83 in}, thickness approx. 1.6 mm {0.063 in}

- (1) Apply ATF (ATF FZ) to the drive plates and driven plates.

-

-

Caution

-

• If the drive plate is replaced with a new one, immerse it in ATF (ATF FZ) for 2 hours or more to permeate the facing with ATF.

- (2) Assemble the drive plates and driven plates. (SKYACTIV-G 1.5)

-

-

Assembly order

-

Drive plate—driven plate—drive plate—driven plate—drive plate—driven plate—driven plate

A :Drive plate

B :Driven plate

- (3) Assemble the drive plates and driven plates. (SKYACTIV-G 2.0, SKYACTIV-G 2.5)

-

-

Assembly order

-

Drive plate—driven plate—drive plate—driven plate—drive plate—driven plate—drive plate

A :Drive plate

B :Driven plate

14. Assemble the reduction planetary gear. (SKYACTIV-G 1.5)

-

Note

-

• If the reduction planetary gear assembly is difficult, assembly is easier if the work is performed using the following procedure:

- (1) Remove the drive plates and driven plates.

-

A :Drive plate

B :Driven plate

- (2) Remove the retaining plate.

-

- (3) Assemble the drive plates and driven plates to the reduction planetary gear shown in the figure.

-

-

Caution

-

• The driven plate has a similar shape to the retaining plate used for the 2-6 brake clearance adjustment. Before assembling the driven plate, always verify the plate thickness and the shape.

-

Note

-

• Drive plate size: Outer diameter approx. 171.9 mm {6.768 in}

• Driven plate size: Inner diameter approx. 148 mm {5.83 in}, thickness approx. 1.6 mm {0.063 in}

• Align the spline positions of the driven plate while assembling.

-

Assembly order

-

Driven plate—driven plate—drive plate—driven plate—drive plate—driven plate—drive plate

A :Drive plate

B :Driven plate

- (4) Assemble the retaining plate to the reduction planetary gear as shown in the figure.

-

-

Note

-

• Retaining plate size: Inner diameter approx. 148 mm {5.83 in}

• Assemble the retaining plate so that the splines of the retaining plate and the splines of the driven plates are positioned as shown in the figure.

- (5) Assemble the parts assembled together in Steps (3) and (4).

-

15. Assemble the reduction planetary gear. (SKYACTIV-G 2.0, SKYACTIV-G 2.5)

-

Note

-

• If the reduction planetary gear assembly is difficult, assembly is easier if the work is performed using the following procedure:

- (1) Remove the drive plates and driven plates.

-

A :Drive plate

B :Driven plate

- (2) Remove the retaining plate.

-

- (3) Assemble the drive plates and driven plates to the reduction planetary gear shown in the figure.

-

-

Caution

-

• The driven plate has a similar shape to the retaining plate used for the 2-6 brake clearance adjustment. Before assembling the driven plate, always verify the plate thickness and the shape.

-

Note

-

• Drive plate size: Outer diameter approx. 171.9 mm {6.768 in}

• Driven plate size: Inner diameter approx. 148 mm {5.83 in}, thickness approx. 1.6 mm {0.063 in}

• Align the spline positions of the driven plate while assembling.

-

Assembly order

-

Drive plate—driven plate—drive plate—driven plate—drive plate—driven plate—drive plate

A :Drive plate

B :Driven plate

- (4) Assemble the retaining plate to the reduction planetary gear as shown in the figure.

-

-

Note

-

• Retaining plate size: Inner diameter approx. 148 mm {5.83 in}

• Assemble the retaining plate so that the splines of the retaining plate and the splines of the driven plates are positioned as shown in the figure.

- (5) Assemble the parts assembled together in Steps (3) and (4).

-

16. To verify that the reduction planetary gear is securely assembled, measure the distance shown in the figure.

-

Note

-

• Recommended measuring instrument: Depth gauge, straight edge ruler

A :Reduction planetary gear end (rear internal gear end)

B :End cover end (alignment surface with transaxle case)

-

Specification

-

61.3—63.1 mm {2.42—2.48 in}

-

• If not within the specification, remove the reduction planetary gear and reassemble.

-

Note

-

- (1) Set two straight edge rulers on the reduction planetary gear (rear internal gear) as shown in the figure.

-

- (2) Measure the positions (2 locations) shown in the figure using a depth gauge and calculate the average value.

-

A :Straight edge ruler

- (3) Subtract the thickness of the straight edge ruler from the average value.

-

17. Assemble the retaining plate using the following procedure:

- (1) Measure the 2-6 brake clearance and select the appropriate retaining plate. (See 2-6 BRAKE CLEARANCE MEASUREMENT/ADJUSTMENT.)

-

-

Note

-

• If the retaining plate is assembled for the 2-6 brake clearance measurement/adjustment, the following retaining plate assembly procedure is not necessary.

- (2) Assemble the retaining plate selected in Step (1).

-

-

Note

-

• Retaining plate: Inner diameter approx. 148 mm {5.83 in}

A :Selection

18. Assemble the springs and retainer component.

-

Note

-

• Springs and retainer component size: Inner diameter approx. 150.6 mm {5.929 in}

19. Assemble the 2-6 brake piston to the brake housing using the following procedure:

- (1) Apply ATF (ATF FZ) to the 2-6 brake piston lip.

-

- (2) Assemble the 2-6 brake piston.

-

20. Assemble the brake housing using the following procedure:

|

1

|

Brake housing

|

|

2

|

8 bolts (M6×1.0 bolt, length to approx. 25 mm {0.98 in})

|

- (1) Assemble the brake housing.

-

- (2) Assemble and tighten the bolts shown in the figure uniformly.

-

-

Caution

-

• If the bolts are not tightened uniformly, the brake housing will slant and parts could be damaged due to the spring force of the springs and retainer component in the brake housing.

-

Note

-

• Bolt size: M6×1.0 bolt, length to approx. 25 mm {0.98 in}

-

Tightening torque

-

8—10 N·m {82—101 kgf·cm, 71—88 in·lbf}

21. Perform an operation verification of the 2-6 brake using the following procedure:

- (1) Blow compressed air into the oil passage shown in the figure and verify the operation condition of the 2-6 brake.

-

-

Warning

-

• Always wear protective eye wear when using the air compressor. Otherwise, ATF or dirt particles blown off by the air compressor could get into the eyes.

-

Note

-

• To prevent damage to parts, always use an air compressor which is adjusted to the indicated pressure.

-

Compressed air pressure

-

0.39—0.44 MPa {4.0—4.4 kgf/cm2, 57—63 psi}

-