|

GENERATOR INSPECTION [MZR 2.0 DISI i-stop]

id011736800300

Generator Warning Light

1. Verify that the battery is fully charged.

2. Verify that the drive belt is correct. (See DRIVE BELT INSPECTION [MZR 2.0 DISI i-stop].)

3. Switch the ignition to ON, verify that the generator warning light illuminates.

4. Verify that the generator warning light goes out after the engine is started.

Generator

Voltage

1. Verify that the battery is fully charged.

2. Verify that the drive belt is correct. (See DRIVE BELT INSPECTION [MZR 2.0 DISI i-stop].)

3. Turn off all electrical loads.

4. Start the engine.

5. Verify that the generator rotates smoothly without any noise while the engine is running.

6. Measure the voltage at each terminal using a tester.

am6zzw00002348

|

Current

1. Verify that the battery is fully charged.

2. Verify that the drive belt is correct. (See DRIVE BELT INSPECTION [MZR 2.0 DISI i-stop].)

3. Remove the battery cover. (See BATTERY REMOVAL/INSTALLATION [MZR 2.0 DISI i-stop].)

4. Disconnect the negative battery cable.

5. Connect a tester, which can read 120 A or more, between generator terminal B and the wiring harness.

6. Connect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION [MZR 2.0 DISI i-stop].)

7. Turn off all electrical loads.

8. Start the engine.

9. Turn the electrical loads (headlights, blower motor, rear window defroster, brake lights, etc.) on and verify that the current reading increases more than the minimum value indicated below.

Generator generated current (reference value) [Conditions] Ambient temperature: 20 °C {68 °F}, Voltage: 12 V, Engine hot

|

Engine speed (rpm) |

Terminal B current (Lower limit of current must be more than 0 A.) |

|

|---|---|---|

|

1,000

|

0—65 A

|

|

|

2,000

|

0—65 A

|

|

PCM and generator shearing inspection

1. Connect the M-MDS to the DLC-2.

am3uuw00003267

|

2. Inspect as follows:

|

Step |

Inspection |

Action |

||

|---|---|---|---|---|

|

1

|

Measure the generator terminal B voltage when the electrical loads*1 are on and off.

|

15 V or more

|

Go to Step 2.

|

|

|

13—15 V

|

Normal*2

|

|||

|

13 V or less

|

Go to Step 3.

|

|||

|

2

|

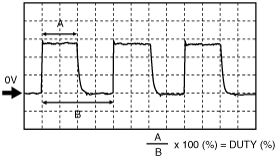

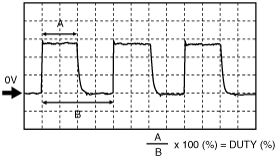

Monitor the ALTT V PID using the M-MDS, (See ON-BOARD DIAGNOSTIC TEST [MZR 2.0 DISI i-stop].) or measure the PCM 2AJ terminal waveform using an oscilloscope. (See PCM INSPECTION [MZR 2.0 DISI i-stop].)

Is the value normal?

|

Yes

|

Go to Step 4.

|

|

|

No

|

Inspect the following, then repair or replace as necessary.

• If there is no malfunction, replace the PCM.

1. Wiring harness between PCM terminal 2AJ- generator terminal P.

2. Wiring harness between PCM terminal 2AI- generator terminal D.

3. Generator inner parts.

|

|||

|

3

|

Monitor the ALTT V PID using the M-MDS, (See ON-BOARD DIAGNOSTIC TEST [MZR 2.0 DISI i-stop].) or measure the PCM 2AJ terminal waveform using an oscilloscope. (See PCM INSPECTION [MZR 2.0 DISI i-stop].)

Is the value normal?

|

Yes

|

Go to Step 5.

|

|

|

No

|

Inspect the following, then repair or replace as necessary.

• If there is no malfunction, replace the PCM.

1. Wiring harness between PCM terminal 2AJ- generator terminal P.

2. Wiring harness between PCM terminal 2AI- generator terminal D.

3. Generator inner parts.

|

|||

|

4

|

Monitor the ALTF PID using the M-MDS, or calculate the duty value of the PCM terminal 2AI using an oscilloscope. Is the duty value 100%?

|

|

Yes

|

Replace PCM.

|

|

No

|

Inspect the following, then repair or replace as necessary.

• If there is no malfunction, replace the PCM.

1. Wiring harness between PCM terminal 2AI- generator terminal D.

2. Generator inner parts.

|

|||

|

5

|

Monitor the ALTF PID using the M-MDS, or calculate the duty value of the PCM terminal 2AI using an oscilloscope. Is the duty value 0%?

|

|

Yes

|

Replace PCM.

|

|

No

|

Inspect the following, then repair or replace as necessary.

• If there is no malfunction, replace the PCM.

1. Wiring harness between PCM terminal 2AI- generator terminal D.

2. Generator inner parts.

|

|||

Generator Inner Parts

Rotor

1. Measure the resistance between the slip rings using a tester.

am6zzw00002350

|

2. Verify that there is no continuity between the slip ring and core using a tester.

am6zzw00002351

|

3. Inspect the slip ring surface condition.

Stator coil

1. Verify that the continuity is as indicated in the table.

am6zzw00002352

|

am6zzw00002353

|

2. Verify that there is no continuity between the stator coil leads and core using a tester.

am3uuw00003268

|

Brush

1. Inspect brushes for wear.

am6zzw00002355

|

Brush spring

1. Measure the force of the brush spring using a spring pressure gauge.

2. Read the spring pressure gauge at the brush tip projection of 2 mm {0.08 in}.

am3uuw00003269

|

Rectifier (Using an analog circuit tester)

1. Inspect for continuity of the diodes using an analog circuit tester.

am6zzw00002357

|

Specification

|

Negative |

Positive |

Continuity |

|---|---|---|

|

E

|

P1, P2, P3, P4, P5, P6

|

Yes

|

|

B

|

No

|

|

|

P1, P2, P3, P4, P5, P6

|

E

|

No

|

|

B

|

Yes

|

Rectifier (Using a digital circuit tester)

1. Inspect for continuity of the diodes using a digital circuit tester.

Specification

|

Negative |

Positive |

Continuity |

|---|---|---|

|

E

|

P1, P2, P3, P4, P5, P6

|

No

|

|

B

|

Yes

|

|

|

P1, P2, P3, P4, P5, P6

|

E

|

Yes

|

|

B

|

No

|

Bearing

1. Inspect for abnormal noise, looseness, and sticking.

am6zzw00002358

|