|

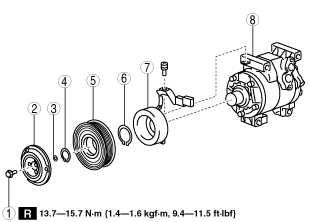

MAGNETIC CLUTCH DISASSEMBLY/ASSEMBLY [FULL-AUTO AIR CONDITIONER]

id0740a1800400

1. Disassemble in the order indicated in the table.

SKYACTIV-G 2.0

am3zzw00010988

|

|

1

|

Bolt

|

|

2

|

Pressure plate

|

|

3

|

Shim

(See Shim Installation Note.)

|

|

4

|

Snap ring

|

|

5

|

A/C compressor pulley

|

|

6

|

Snap ring

|

|

7

|

Stator

|

|

8

|

A/C compressor body

|

MZR 2.5, MZR 2.3 DISI Turbo

am3zzw00010989

|

|

1

|

Bolt

|

|

2

|

Pressure plate

|

|

3

|

Shim

(See Shim Installation Note.)

|

|

4

|

Snap ring

|

|

5

|

A/C compressor pulley

|

|

6

|

Snap ring

|

|

7

|

Stator

|

|

8

|

A/C compressor body

|

MZR 2.0, MZR 2.0 DISI i-stop

am3zzw00010990

|

|

1

|

Bolt

|

|

2

|

Pressure plate

|

|

3

|

Shim

(See Shim Installation Note.)

|

|

4

|

Snap ring

|

|

5

|

A/C compressor pulley

|

|

6

|

Snap ring

|

|

7

|

Stator

|

|

8

|

A/C compressor body

|

MZR 1.5, MZR 1.6

am3zzw00010991

|

|

1

|

Bolt

|

|

2

|

Pressure plate

|

|

3

|

Shim

(See Shim Installation Note.)

|

|

4

|

Snap ring

|

|

5

|

A/C compressor pulley

|

|

6

|

Screw

(See Screw Installation Note.)

|

|

7

|

Clamp

(See Clamp Installation Note.)

|

|

8

|

Screw

(See Screw Installation Note.)

|

|

9

|

Stator and thermal protector

|

|

10

|

A/C compressor body

|

MZ-CD 1.6

am3zzw00009996

|

|

1

|

Nut

|

|

2

|

Pressure plate

|

|

3

|

Shim

(See Shim Installation Note.)

|

|

4

|

Snap ring

|

|

5

|

A/C compressor pulley

|

|

6

|

Snap ring

|

|

7

|

Stator

|

|

8

|

O-ring

|

|

9

|

Bolt

|

|

10

|

Bracket

|

|

11

|

A/C compressor body

|

MZR-CD 2.2

am3zzw00010992

|

|

1

|

Bolt

|

|

2

|

Pressure plate

|

|

3

|

Shim

(See Shim Installation Note.)

|

|

4

|

Snap ring

|

|

5

|

A/C compressor pulley

|

|

6

|

Clamp

(See Clamp Installation Note.)

|

|

7

|

Screw

(See Screw Installation Note.)

|

|

8

|

Screw

(See Screw Installation Note.)

|

|

9

|

Stator and thermal protector

|

|

10

|

A/C compressor body

|

2. Assemble in the reverse order of disassembly.

3. Adjust the magnetic clutch clearance. (See MAGNETIC CLUTCH ADJUSTMENT [FULL-AUTO AIR CONDITIONER].)

Bolt Removal/Installation Note (MZR 1.5, MZR 1.6, MZR-CD 2.2)

1. When removing or installing the bolt, hold the pressure plate in place as shown in the figure.

am3zzw00010993

|

2. When installing a new A/C compressor body, replace the recommended bolt.

Bolt Removal/Installation Note (SKYACTIV-G 2.0, MZR 2.0, MZR 2.0 DISI i-stop, MZR 2.3 DISI Turbo, MZR 2.5)

1. When removing or installing the bolt, lock the A/C compressor pulley against rotation using the following procedure

am3zzw00011945

|

am3zzw00010994

|

2. When installing a new A/C compressor body, replace the recommended bolt.

Nut Removal/Installation Note (MZ-CD 1.6)

1. When removing or installing the nut, lock the A/C compressor pulley against rotation using the following procedure

am3zzw00010995

|

am3zzw00010996

|

2. When installing a new A/C compressor body, replace the recommended nut.

Stator and Thermal Protector Removal Note

1. After removing the stator and thermal protector, completely remove the silicone adhering to the A/C compressor side.

Stator and Thermal Protector Installation Note

1. Apply approx. 1 g {0.04 oz} of silicone (Shin-Etsu Silicone KE-347W or similar) to the contact surface of the thermal protector, then thoroughly install it onto the A/C compressor, leaving no gaps.

am3zzw00010997

|

A/C Compressor Pulley Removal Note

1. Remove the A/C compressor pulley using the SSTs (49 0839 425C, 49 SE01 160).

acxuuw00002994

|

am3zzw00010998

|

A/C Compressor Pulley Installation Note

1. Install the inner wheel of the pulley using SST (49 D034 202) to the compressor.

acxuuw00002995

|

Snap Ring Removal/Installation Note

1. Remove/install the snap ring using a snap ring pliers.

am3zzw00010999

|

Screw Installation Note

1. When installing a new stator, replace the screw.

O-ring Installation Note

1. When installing a new oil plug, replace the O-ring.

Clamp Installation Note

1. When installing a new stator and thermal protector, replace the clamp.

Shim Installation Note

1. First, insert the 1mm (0.039 in) thick shim into the shaft.

am3zzw00011000

|