1. Perform the spark test and identify the malfunctioning cylinder. (See NO.27 SPARK PLUG CONDITION [LF, L3].)

2. Replace the ignition coil of the malfunctioning cylinder with that of a normal cylinder, and reperform the spark test. (See NO.27 SPARK PLUG CONDITION [LF, L3].)

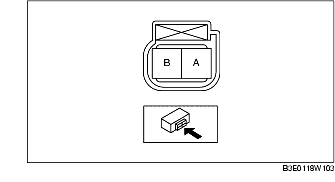

1. Disconnect the ignition coil connector.

2. Measure the resistance between the following terminals using an ohmmeter:

- If not within the specification, replace the ignition coil.

1. Disconnect the ignition coil connector.

2. Remove the ignition coil. (See IGNITION COIL REMOVAL/INSTALLATION [LF, L3].)

3. Measure the resistance between the following using an ohmmeter:

- If not within the specification, replace the ignition coil.

1. Disconnect the ignition coil connector.

2. Measure the insulation resistance from terminal A to ignition coil case using an ohmmeter.