MASS AIR FLOW (MAF) SENSOR INSPECTION [LF, L3]

id0140a6800700

-

Note

-

• Before performing the following inspection, make sure to follow the procedure as indicated in the troubleshooting flowchart.

Visual Inspection

1. Visually inspect the MAF sensor for the following:

-

• Damage, cracks

-

• Rusted sensor terminal

-

• Bent sensor terminal

-

- If there is any malfunction, replace the MAF sensor.

-

- If the monitor item status/specification (reference) is not within the specification even though there is no malfunction, perform the "Circuit Open/Short Inspection".

Voltage Inspection

1. Remove the MAF/IAT sensor without disconnect the MAF/IAT sensor connector.

2. Turn the ignition switch to the ON position.

3. As the air gradually approaches the MAF detection part of the MAF/IAT sensor, verify that the voltage at PCM terminal 1AC (WDS PID: MAF) varies.

-

• If it cannot be verified even though the related harnesses have no malfunction, replace the MAF/IAT sensor.

Circuit Open/Short Inspection

1. Disconnect the PCM connector. (See PCM REMOVAL/INSTALLATION [LF, L3].)

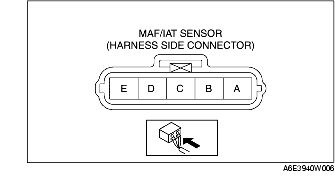

2. Disconnect the MAF sensor connector.

3. Inspect the following wiring harnesses for open or short. (Continuity check)

Open circuit

-

• If there is no continuity, the circuit is open. Repair or replace the harness.

-

- MAF sensor terminal A and main relay terminal E

-

- MAF sensor terminal B and PCM terminal 1BD

-

- MAF sensor terminal C and PCM terminal 1AC

Short circuit

-

• If there is continuity, the circuit is shorted. Repair or replace the harness.

-

- MAF sensor terminal A and body GND

-

- MAF sensor terminal C and power supply

-

- MAF sensor terminal C and body GND

-

- MAF sensor terminal B and power supply