1. Inspect the engine coolant level. (See COOLING SYSTEM SERVICE WARNINGS.) (See ENGINE COOLANT LEVEL INSPECTION.)

2. Inspect the engine oil level. (See ENGINE OIL LEVEL INSPECTION [ZY, Z6].) (See ENGINE OIL LEVEL INSPECTION [LF, L3].)

3. Inspect the ATF level. (See Automatic Transaxle Fluid (ATF) Level Inspection.)

4. Inspect the ignition timing. (See Ignition Timing Inspection.) (See Ignition Timing Inspection.)

5. Inspect the idle speed. (See Idle Speed Inspection.) (See Idle Speed Inspection.)

6. Bring up the engine and transaxle to normal operating temperature.

Z6

LF

L3

1. Perform road test preparation. (See Road Test Preparation.)

2. Shift the selector lever to D range.

3. Accelerate the vehicle at half and wide open.

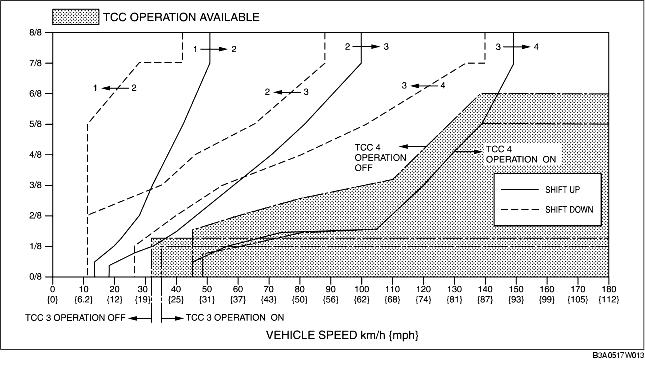

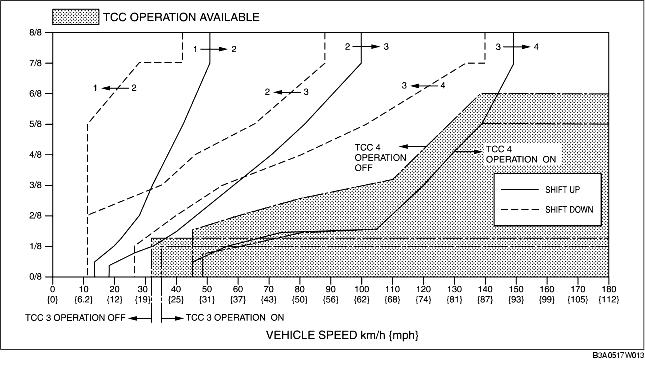

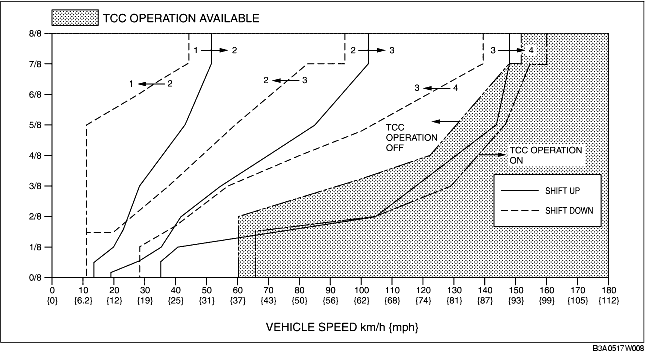

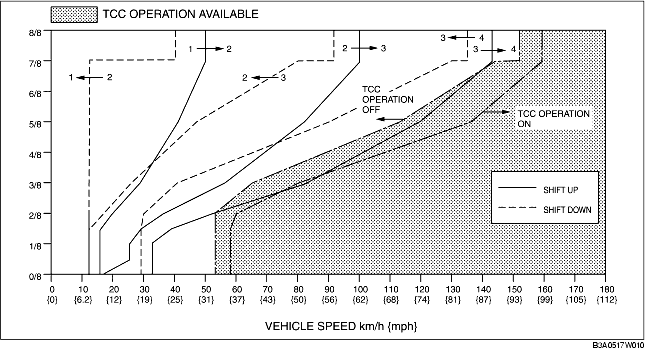

4. Verify that 1→2, 2→3, and 3→4 upshifts and downshifts are obtained. The shift points must be as shown in the table below.

5. Drive the vehicle in 4GR, 3GR, and 2GR and verify that kickdown occurs for 4→3, 3→2, 2→1 downshifts, and that the shift points are as shown in the table below.

6. Decelerate the vehicle and verify that engine braking effect is felt in 2GR, 3GR and 4GR.

7. Drive the vehicle and verify that TCC operation is obtained. The operation points must be as shown in the table below.

Vehicle speed at shift point table (ZY)

Vehicle speed at shift point table (Z6)

Vehicle speed at shift point table (LF)

Vehicle speed at shift point table (L3)

1. Perform road test preparation. (See Road Test Preparation.)

2. Shift the selector lever to M range.

3. Verify that 1→2, 2→3, and 3→4 upshifts and 4→3, 3→2, and 2→1 downshifts are obtained by manual shifting of the selector lever forward and back.

4. Decelerate the vehicle and verify that 4→3, 3→1 downshifts are obtained. The shift points must be as shown in the table below.

5. Decelerate the vehicle and verify that engine braking effect is felt in all gears.

Vehicle speed at shift point table (ZY)

Vehicle speed at shift point table (Z6)

Vehicle speed at shift point table (LF)

Vehicle speed at shift point table (L3)

1. Shift into P position on a gentle slope. Release the brake and verify that the vehicle does not roll.