|

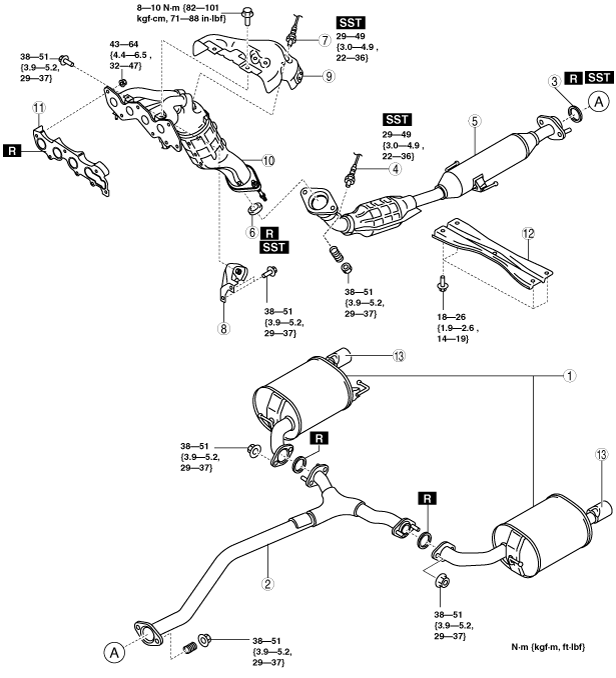

EXHAUST SYSTEM REMOVAL/INSTALLATION [MZR 2.0 DISI]

id0115c8800200

1. Disconnect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION [MZR 2.0 DISI].)

2. Remove the plug hole plate. (See PLUG HOLE PLATE REMOVAL/INSTALLATION [MZR 2.0 DISI].)

3. Remove in the order indicated in the table.

4. Remove the exhaust system insulator. (See Exhaust System Insulator Removal/installation Note.)

5. Install in the reverse order of removal.

am6zzw00005767

|

|

1

|

Main silencer

|

|

2

|

Middle pipe

|

|

3

|

Seal ring (rear side)

(See Seal Ring Removal Note.)

|

|

4

|

HO2S

|

|

5

|

TWC

|

|

6

|

Seal ring (front side)

(See Seal Ring Removal Note.)

|

|

7

|

A/F sensor

|

|

8

|

Exhaust manifold bracket

|

|

9

|

Exhaust manifold upper insulator

|

|

10

|

Exhaust manifold

|

|

11

|

Exhaust manifold gasket

|

|

12

|

Tunnel member

|

|

13

|

Tailpipe garnish

|

Exhaust System Insulator Removal/installation Note

1. Remove the exhaust system insulator in the order shown in the figure.

2. Install in the reverse order of removal.

am6zzw00005768

|

|

1

|

Insulator (front)

|

|

2

|

Insulator (middle)

|

|

3

|

Insulator (rear)

|

Insulator (rear) Removal Note

1. Push out the mandrel using a hammer and punch (2—2.8 mm {0.08—0.11 in} diameter).

am6zzw00005769

|

2. Remove the flange using a drill (5 mm {0.20 in} drill bit).

am6zzw00005770

|

Seal Ring Removal Note

1. Remove the seal ring using a flathead screwdriver being careful not to damage the pipe.

am6zzw00005771

|

Exhaust Manifold Bracket Removal Note

1. Remove the aerodynamic under cover No.2. (See AERODYNAMIC UNDER COVER NO.2 REMOVAL/INSTALLATION.)

2. Remove the exhaust manifold bracket.

Tailpipe Garnish Replacement Note

1. Remove the spot welding on the damaged tailpipe garnish.

2. Install a new tailpipe garnish as shown in the figure.

am6zzw00005781

|

Flange Surface Installation Note

1. Sand the surface shown in the figure using sandpaper and remove sanding residue, accumulated matter, and friction marks.

2. Degrease the sanded surface.

am6zzw00011898

|

Exhaust Manifold Installation Note

1. Temporarily tighten the exhaust manifold installation nuts.

2. Tighten the exhaust manifold installation nuts in the order shown in the figure.

am6zzw00005772

|

Exhaust Manifold Upper Insulator Installation Note

1. Temporarily tighten the exhaust manifold insulator.

2. Tighten the exhaust manifold insulator in the order shown in the figure.

am6zzw00005773

|

Seal Ring (Front Side) Installation Note

1. Temporarily install the seal ring to the pipe so that the seal ring is even with the flange.

am6zzw00005778

|

2. Install the SST to the seal ring so that the SST is even with the flange.

am6zzw00005779

|

3. Press in the seal ring by tapping the SST using a plastic hammer until the seal ring contacts the flange.

am6zzw00005780

|

Seal Ring (Rear Side) Installation Note

1. Temporarily install the seal ring to the pipe so that the seal ring is even with the flange.

am6zzw00005774

|

2. Install the SST to the seal ring so that the SST is even with the flange.

am6zzw00005775

|

3. Press in the seal ring by tapping the SST using a plastic hammer until the seal ring contacts the flange.

am6zzw00005776

|