FLYWHEEL INSPECTION [A26M-R]

id0510m8800100

1. Remove the manual transaxle. (See MANUAL TRANSAXLE REMOVAL/INSTALLATION [A26M-R].)

2. Remove the clutch cover and clutch disc. (See CLUTCH UNIT REMOVAL/INSTALLATION [A26M-R].)

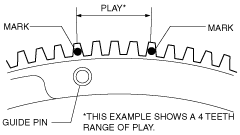

3. Inspect the rotation of the dual-mass flywheel for play.

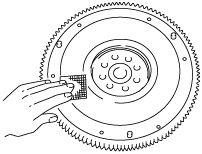

- (1) Lock the dual-mass flywheel using the SST (49 E011 1A0).

-

- (2) Rotate the secondary flywheel clockwise by hand until resistance can be felt.

-

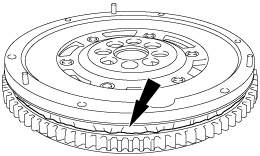

- (3) Mark the guide pin position on the ring gear of the flywheel.

-

- (4) Rotate the secondary flywheel counterclockwise by hand until resistance can be felt.

-

- (5) Mark the guide pin position on the ring gear of the primary flywheel again.

-

- (6) Verify that the play is within the range of 4 teeth.

-

-

-

Caution

-

• It may not be possible to rotate the secondary flywheel due to the functionality of the dual-mass flywheel.

In this case, the dual-mass flywheel can be considered normal by reason of the play being within the range of 4 teeth.

4. Inspect the flywheel for cracks, and the ring gear of the flywheel for damage and tooth wear.

-

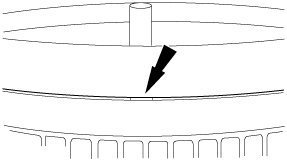

5. Inspect the clutch disc surface of the flywheel for damage, loss, and discoloration.

-

• If there is any malfunction, correct slight scratches and discoloration using sandpaper.

6. Inspect for locating dowels touching the primary mass of the dual-mass flywheel.

-

Caution

-

• Make sure that the three locating dowels are installed.

-

7. Visually inspect the secondary mass.

-

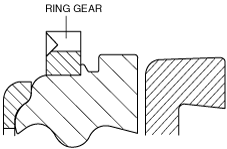

8. Visually inspect the ring gear on the dual-mass flywheel.

-

9. Inspect the welded area of the dual-mass flywheel for grease leakage.

-

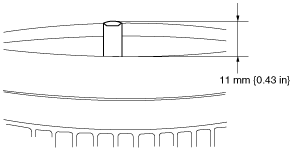

10. Inspect the dual-mass flywheel for the amount of guide pin projection.

-

11. Install in the reverse order of removal.

12. Perform the auto leveling system initialization. (See AUTO LEVELING SYSTEM INITIALIZATION.)

13. Add the specified amount of specified transaxle oil. (See TRANSAXLE OIL REPLACEMENT [A26M-R].)