|

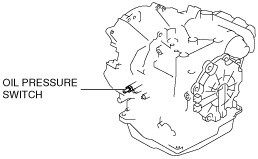

OIL PRESSURE SWITCH INSPECTION [FS5A-EL]

id051721805900

On-vehicle Inspection

1. Remove the aerodynamic under cover NO.2. (See AERODYNAMIC UNDER COVER NO.2 REMOVAL/INSTALLATION.)

2. Disconnect the oil pressure switch connector.

am8rrw00002344

|

3. Start the engine.

4. Inspect that there is no continuity between oil pressure switch terminal A and body GND.

5. Firmly depress the brake pedal with the left foot.

6. Select the selector lever to D range.

7. Verify that there is continuity between oil pressure switch terminal A and body GND.

am6zzw00004877

|

Off-vehicle inspection

1. Apply air pressure at 400—440 kPa {4.08—4.48 kgf/cm2, 58.1—63.8 psi} shown in the figure.

am6zzw00005449

|

2. Inspect continuity between the oil pressure switch terminal A and screw part.

am6zzw00004877

|

Oil pressure switch specification

|

Test condition |

Continuity |

|---|---|

|

Applying air pressure

|

Continuity

|

|

Applying no air pressure

|

No continuity

|