|

am6zzw00001180

DTC C200D:1C/C200D:62

id060200817200

|

DTC

|

C200D:1C/C200D:62

|

Resolver sensor

|

|

|

DETECTION CONDITION

|

• C200D:1C

• C200D:62

|

||

|

POSSIBLE CAUSE

|

• Open or short to ground circuit in wiring harness between the following EPS control module terminals and resolver sensor terminals

• Resolver sensor malfunction

• EPS control module malfunction

• Poor connection at connectors

|

||

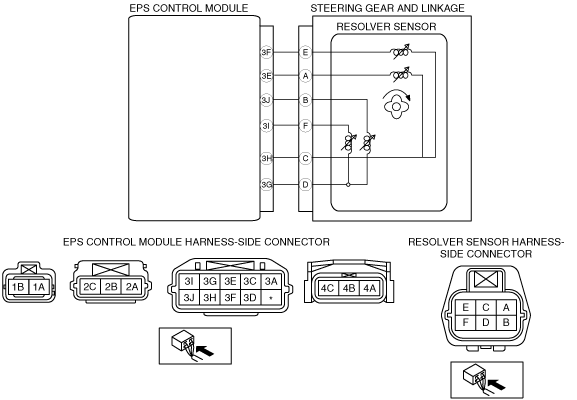

System wiring diagram

am6zzw00001180

|

Diagnostic Procedure

|

Step |

Inspection |

Action |

|

|---|---|---|---|

|

1

|

INSPECT WHETHER MALFUNCTION IS CAUSED BY POOR CONNECTION OF EPS CONTROL MODULE OR PIN DEFORMATION

• Inspect connection of the EPS control module and wiring harness.

• Disconnect the EPS control module connector.

• Inspect whether malfunction is caused by bent or poorly connected EPS control module connector pin.

• Are the connector connection, connector pins, and wiring harness normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the faulty connector wiring harness, then go to Step 5.

|

||

|

2

|

IINSPECT RESOLVER SENSOR CIRCUIT FOR OPEN CIRCUIT

• Inspect for continuity between the EPS control module terminals and resolver sensor terminals.

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness for open circuit between the EPS control module and resolver sensor, then go to Step 5.

|

||

|

3

|

INSPECT RESOLVER SENSOR CIRCUIT FOR SHORT TO POWER

• Measure the voltage between the resolver sensor terminals and ground.

• Is there any B+?

|

Yes

|

Repair or replace the wiring harness for short to power between the EPS control module and resolver sensor, then go to Step 5.

|

|

No

|

Go to the next step.

|

||

|

4

|

INSPECT RESOLVER SENSOR CIRCUIT FOR SHORT TO GROUND

• Inspect for continuity between the torque sensor terminals and ground.

• Is there continuity?

|

Yes

|

Repair or replace the wiring harness for short to ground between the EPS control module and resolver sensor, then go to the next step.

|

|

No

|

Replace the steering gear and linkage (resolver sensor), then go to the next step.

|

||

|

5

|

VERIFY THAT SAME DTC IS NOT PRESENT

• Make sure to reconnect all disconnected connectors.

• Clear the DTC from the memory.

• Is the same DTC present?

|

Yes

|

Repeat the inspection from Step 1.

If the malfunction recurs, replace the EPS control module.

|

|

No

|

Go to the next step.

|

||

|

6

|

VERIFY THAT NO OTHER DTCs ARE PRESENT

• Are any other DTCs output?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|

||