|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

• Record the freeze frame data/snap shot data.

|

—

|

Go to the next step.

|

|

2

|

VERIFY OTHER RELATED DTCs

• Switch the ignition OFF, and then switch it ON (engine off).

• Display the DTCs using the M-MDS.

• Has any DTC other than P06DE:00 been stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

3

|

VERIFY THAT THERE IS NO ENGINE OIL LEAKAGE

• Start the engine and verify that there is no engine oil leakage in the hydraulic circuit.

• Is there oil leakage from the oil passage?

|

Yes

|

Repair or replace the malfunctioning location and add genuine engine oil.

Go to Step 14.

|

|

No

|

Go to the next step.

|

|

4

|

INSPECT ENGINE OIL LEVEL

• Inspect the engine oil level.

• Is the engine oil level sufficient?

|

Yes

|

Go to the next step.

|

|

No

|

Add genuine engine oil, then go to the next step.

|

|

5

|

INSPECT ENGINE OIL SOLENOID VALVE CONNECTOR CONDITION

• Switch the ignition OFF.

• Disconnect the engine oil solenoid valve connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 14.

|

|

6

|

INSPECT ENGINE OIL TEMPERATURE/ENGINE OIL PRESSURE SENSOR CONNECTOR CONDITION

• Disconnect the engine oil temperature/engine oil pressure sensor connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 14.

|

|

7

|

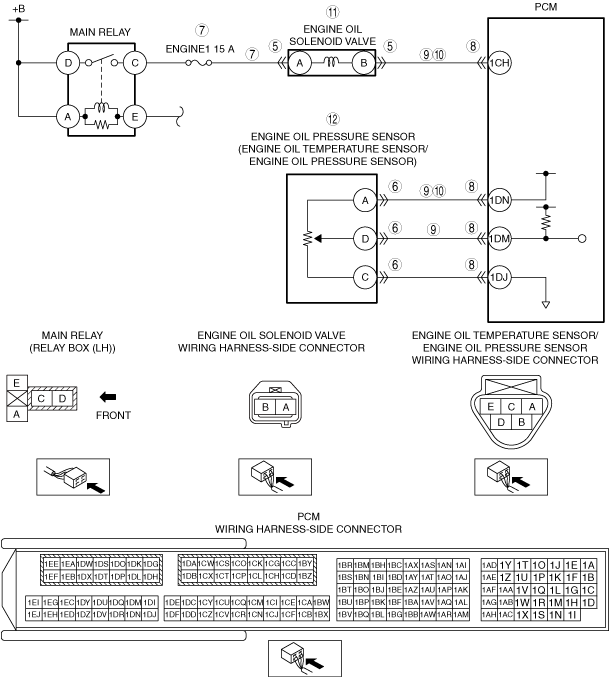

INSPECT ENGINE OIL SOLENOID VALVE POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT OR SHORT TO GROUND

• Verify that the engine oil solenoid valve connector is disconnected.

• Switch the ignition ON (engine off).

-

Note

-

• Another DTC may be stored by the PCM detecting an open circuit.

• Measure the voltage at engine oil solenoid valve terminal A (vehicle wiring harness side).

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the ENGINE1 15 A fuse.

• If the fuse is blown:

-

― Refer to the wiring diagram and verify if there is a common connector between main relay terminal C and engine oil solenoid valve terminal A.

If there is a common connector:

-

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for short to ground to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

-

• Repair or replace the wiring harness which is shorted to ground.

• Replace the fuse.

• If the fuse is damaged:

-

― Replace the fuse.

• If the fuse is normal:

-

― Refer to the wiring diagram and verify if there is a common connector between main relay terminal C and engine oil solenoid valve terminal A.

If there is a common connector:

-

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

-

• Repair or replace the wiring harness which has an open circuit.

Go to Step 14.

|

|

8

|

INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 14.

|

|

9

|

INSPECT ENGINE OIL SOLENOID VALVE CIRCUIT AND ENGINE OIL PRESSURE SENSOR CIRCUIT FOR SHORT TO GROUND

• Verify that the engine oil solenoid valve connector and the engine oil temperature sensor/engine oil pressure sensor connector are disconnected.

• Switch the ignition OFF.

• Inspect for continuity between the following terminals (vehicle wiring harness) and ground.

-

― Engine oil solenoid valve terminal B

― Engine oil temperature sensor/engine oil pressure sensor terminal A

― Engine oil temperature sensor/engine oil pressure sensor terminal D

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Engine oil solenoid valve terminal B and PCM terminal 1CH

• Engine oil temperature/engine oil pressure sensor terminal A and PCM terminal 1DN

• Engine oil temperature/engine oil pressure sensor terminal D and PCM terminal 1DM

If there is a common connector:

-

― Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for short to ground to determine the malfunctioning location.

― Repair or replace the malfunctioning location.

If there is no common connector:

-

― Repair or replace the wiring harness which is shorted to ground.

Go to Step 14.

|

|

No

|

Go to the next step.

|

|

10

|

INSPECT ENGINE OIL SOLENOID VALVE CIRCUIT AND ENGINE OIL PRESSURE SENSOR CIRCUIT FOR OPEN CIRCUIT

• Verify that the engine oil solenoid valve connector, engine oil temperature sensor/engine oil pressure sensor connector, and PCM connector are disconnected.

• Inspect the wiring harness for continuity between the following terminals (vehicle wiring harness side).

-

― Engine oil solenoid valve terminal B and PCM terminal 1CH

― Engine oil temperature/engine oil pressure sensor terminal A and PCM terminal 1DN

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Engine oil solenoid valve terminal B and PCM terminal 1CH

• Engine oil temperature/engine oil pressure sensor terminal A and PCM terminal 1DN

If there is a common connector:

-

― Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

― Repair or replace the malfunctioning location.

If there is no common connector:

-

― Repair or replace the wiring harness which has an open circuit.

Go to Step 14.

|

|

11

|

INSPECT ENGINE OIL SOLENOID VALVE

• Inspect the engine oil solenoid valve.

• Is the engine oil solenoid valve normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the engine oil solenoid valve, then go to Step 14.

|

|

12

|

INSPECT ENGINE OIL PRESSURE SENSOR

• Reconnect all the disconnected connectors.

• Inspect the engine oil pressure sensor.

• Is the engine oil pressure sensor normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the engine oil temperature/engine oil pressure sensor, then go to Step 14.

|

|

13

|

INSPECT OIL STRAINER

• Inspect the oil strainer for clogging.

• Is the oil strainer normal?

|

Yes

|

Replace the oil pump, then go to the next step.

|

|

No

|

Replace the oil strainer, then go to the next step.

|

|

14

|

VERIFY THAT REPAIRS HAVE BEEN COMPLETED

• Reconnect all disconnected connectors and hoses.

• Refer to the [MEMORY CLEARING PROCEDURE] and clear the DTC.

• Start the engine and drive the vehicle under the freeze frame data/snapshot data condition.

-

Warning

-

• To prevent an accident, work with another person when the vehicle is being driven (one person drives vehicle, other person operates M-MDS).

• Observe legal speed limits when driving the vehicle and perform the procedure in a location where safety can be assured.

• Display the DTCs using the M-MDS.

• Has DTC P06DE:00 been recorded?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

|

15

|

VERIFY OTHER DTCs

• Has any other DTC or pending code been stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|