|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

• Record the freeze frame data/snap shot data.

|

—

|

Go to the next step.

|

|

2

|

VERIFY IF MALFUNCTION IS CAUSED BY OVERHEATING

• Verify the vehicle engine condition.

• Is the engine overheating?

|

Yes

|

Perform malfunction diagnosis according to [NO.22 COOLING SYSTEM MALFUNCTION (OVERHEAT)].

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT ECT SENSOR CONNECTOR CONDITION

• Switch the ignition OFF.

• Disconnect the ECT sensor connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 8.

|

|

4

|

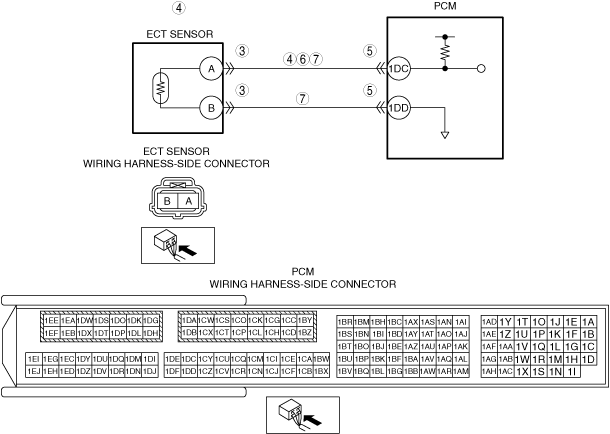

DETERMINE IF MALFUNCTION IS CAUSED BY ECT SENSOR MALFUNCTION OR WIRING HARNESS SIDE MALFUNCTION

• Verify that the ECT sensor connector is disconnected.

• Switch the ignition ON (engine off).

-

Note

-

• Another DTC may be stored by the PCM detecting an open circuit.

• Measure the voltage at ECT sensor terminal A (vehicle wiring harness side).

• Is the voltage approx. 5 V?

|

Yes

|

Replace the ECT sensor, then go to Step 8.

|

|

No

|

Go to the next step.

|

|

5

|

INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 8.

|

|

6

|

INSPECT ECT SENSOR SIGNAL CIRCUIT FOR SHORT TO GROUND

• Verify that the ECT sensor connector and the PCM connector are disconnected.

• Switch the ignition OFF.

• Inspect for continuity between ECT sensor terminal A (vehicle wiring harness side) and body ground.

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between ECT sensor terminal A and PCM terminal 1DC.

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for short to ground to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which is shorted to ground.

Go to Step 8.

|

|

No

|

Go to the next step.

|

|

7

|

INSPECT ECT SENSOR SIGNAL CIRCUIT AND GROUND CIRCUIT FOR SHORT CIRCUIT

• Verify that the ECT sensor connector and the PCM connector are disconnected.

• Inspect for continuity between ECT sensor terminals A and B (vehicle wiring harness side).

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• ECT sensor terminal A and PCM terminal 1DC

• ECT sensor terminal B and PCM terminal 1DD

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for short circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the malfunctioning wiring harness.

Go to the next step.

|

|

No

|

Go to the next step.

|

|

8

|

VERIFY THAT REPAIRS HAVE BEEN COMPLETED

• Reconnect all the disconnected connectors.

• Refer to the [MEMORY CLEARING PROCEDURE] and clear the DTC.

• Perform the KOEO or KOER self-test.

• Has DTC P0117:00 been recorded?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

|

9

|

VERIFY OTHER DTCs

• Has any other DTC or pending code been stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|