DTC P21CE:00

Reductant quality module performance

DETECTION CONDITION

• The PCM detects any of the following for a continuous 5 s.

-

― Urea quality sensor power supply voltage: Less than 4.33 V― Any of the following is detected for 0.5 s or more

-

• Analog/digital conversion processing time: 500 msec or more• Error in analog/digital conversion results

― The following comparison results do not match-

• Check sum data calculated when AdBlue® quality sensor is starting• Check sum data stored in urea quality sensor

― The following comparison results do not match-

• Sensor characteristics calculated when urea quality sensor is starting• Sensor characteristics stored in urea quality sensor

― Heater voltage in urea quality sensor is less than 0.2 V or exceeds 4.8 V when heater is on― Heater voltage in urea quality sensor is less than 0.02 V or exceeds 0.2 V when heater is off― Input current is less than 0.02 A or exceeds 0.1 A when heater in urea quality sensor turns on― Communication error between CPU and digital potentiometer in urea quality sensor -

MONITORING CONDITIONS

• AdBlue® amount in the urea tank: 61—400 mm {2.5—15.7 in}

• Above 9 s have elapsed after the ignition was switched ON

• The following DTCs are not detected

-

― Urea quality sensor: U02A2:00

Diagnostic support note

• This is a continuous monitor (other).

• The check engine light illuminates if the PCM detects the above malfunction condition during the first drive cycle.

• FREEZE FRAME DATA/Snapshot data is available.

• DTC is stored in the PCM memory.

-

Note

-

• When this DTC is detected, inducement DTC P2BAF:00 is also detected

FAIL-SAFE FUNCTION

• The instrument cluster warns the driver with the following functions.

-

― Selective catalytic reduction (SCR) system warning light― Buzzer― Message

-

Note

-

• The remaining distance to empty is a maximum of 700 km {435 mile} until the malfunction targeted by inducement (laws and regulations requirement) is repaired. This distance is displayed in the instrument cluster and counts down until the targeted malfunction is repaired.• Perform the following restrictions while driving the vehicle according to the remaining distance to empty.

-

― 700 to 650 km {435 to 404 miles}: No restriction― 650 to 0 km {404 to 0 miles}: Maximum vehicle speed is restricted from 80 to 50 km/h {50 to 31 mph}― 0 km {0 miles}: Engine speed is fixed at idle speed

-

-

POSSIBLE CAUSE

• Dosing control unit malfunction

• Urea quality sensor connector or terminals malfunction

• Dosing control unit connector or terminals malfunction

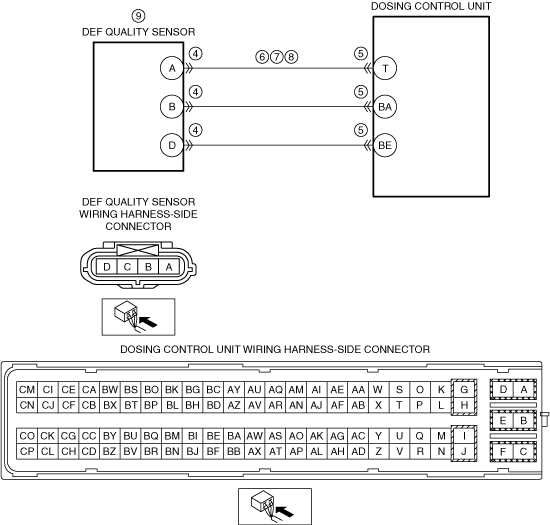

• Open or short circuit in wiring harness between urea quality sensor terminal A and dosing control unit terminal T

• Urea quality sensor malfunction

-

― Power supply circuit in urea quality sensor― CPU in urea quality sensor― Heater in urea quality sensor

• Dosing control unit malfunction

• PCM malfunction