DTC P0841

Oil pressure switch circuit malfunction

DETECTION CONDITION

• When each of DTC P0731, P0732, P0733 and P0734 are not generated and 10 seconds or more passed.

-

― When all conditions below satisfied while driving in 1GR, 2GR or 3GR.

-

• ATF temperature 20 °C {68 °F} or above.• Oil pressure switch OFF• Revolution ratio of forward clutch drum revolution to differential gear case revolution below 0.91 or more than 3.08.• Any of the following not generated: DTC P0500, P0706, P0707, P0708, P0712, P0713, P0715, P0751, P0752, P0753, P0756, P0757, P0758, P0761, P0762, P0763, P0766, P0767, P0768, P0771, P0772, P0773.

-

-

― When all conditions below satisfied with driving in 4GR.

-

• ATF temperature 20 °C {68 °F} or above.• Oil pressure switch ON• Revolution ratio of forward clutch drum revolution to differential gear case revolution below 0.64 or more than 0.82.• Any of the following not generated: DTC P0500, P0706, P0707, P0708, P0712, P0713, P0715, P0751, P0752, P0753, P0756, P0757, P0758, P0761, P0762, P0763, P0766, P0767, P0768, P0771, P0772, P0773.

-

Diagnostic support note:

• This is a continuous monitor (CCM).

• MIL illuminates if PCM detects the above malfunction condition in two consecutive drive cycles or in one drive cycle while the DTC for the same malfunction has been stored in the PCM.

• PENDING CODE is not available.

• FREEZE FRAME DATA is not available.

• HOLD indicator light flashes.

• DTC is stored in the PCM memory.

POSSIBLE CAUSE

• Oil pressure switch malfunction

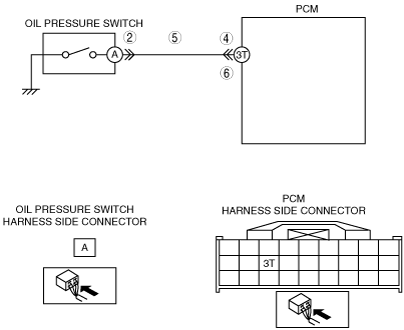

• Open circuit between oil pressure switch terminal A and PCM terminal 3T

• Short to ground between oil pressure switch terminal A and PCM terminal 3T

• Damaged connector between oil pressure switch and PCM

• PCM malfunction