|

TIMING BELT REMOVAL/INSTALLATION [MZR-CD (RF Turbo)]

id0110f1804000

1. Disconnect the negative battery cable.

2. Remove the front tire (RH).

3. Set the front mudguard (RH) out of the way. (See FRONT MUDGUARD REMOVAL/INSTALLATION.)

4. Remove the aerodynamic under cover No.2. (See AERODYNAMIC UNDER COVER NO.2 REMOVAL/INSTALLATION.)

5. Remove the splash shield (RH).

6. Set the coolant reserve tank out of the way. (See COOLANT RESERVE TANK REMOVAL/INSTALLATION [MZR-CD (RF Turbo)].)

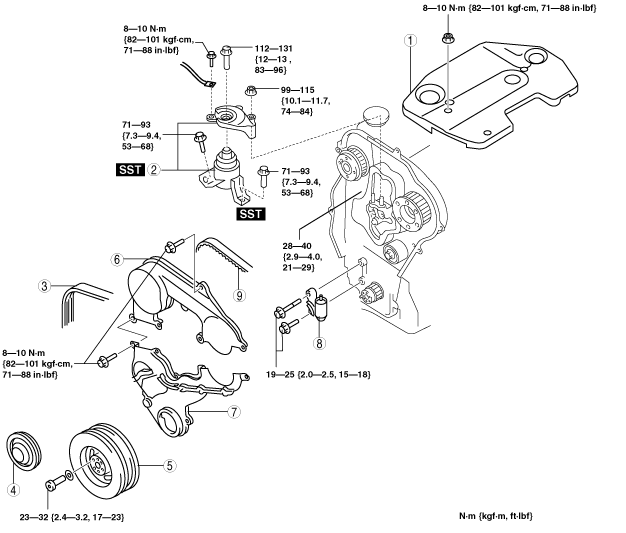

7. Remove in the order shown in the table.

8. Install in the reverse order of removal.

9. Start the engine and inspect the pulleys and the drive belt for runout and contact.

am6zzw00003110

|

|

1

|

Engine cover

|

|

2

|

No.3 engine mount

|

|

3

|

Drive belt

|

|

4

|

Crankshaft pulley cover

|

|

5

|

Crankshaft pulley

|

|

6

|

Upper timing belt cover

|

|

7

|

Lower timing belt cover

|

|

8

|

Timing belt auto tensioner

|

|

9

|

Timing belt

|

No.3 Engine Mount Removal Note

1. Air cleaner assembly. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [MZR-CD (RF Turbo)].)

2. Install the SST using the following procedure.

am6zzw00000924

|

am6zzw00000925

|

am6zzw00000926

|

3. Support the engine using the SST.

am6zzw00000927

|

Timing Belt, Timing Belt Auto Tensioner Removal Note

am6zzw00003618

|

1. Turn the crankshaft clockwise and align the timing marks as shown.

am5ezw00006554

|

2. Remove the timing belt auto tensioner.

Timing Belt, Timing Belt Auto Tensioner Installation Note

1. Measure the tensioned rod projection length.

am3zzw00004166

|

2. Inspect the timing belt auto tensioner for oil leakage.

3. Verify the thrust of the timing belt auto tensioner rod in the following order:

am3zzw00004167

|

4. Verify that all timing marks are correctly aligned.

5. Fix the camshaft pulley to the cylinder head using bolt (M8 x1.25).

am5ezw00006555

|

6. Install the timing belt on the pulleys in the order shown below.

am3zzw00004298

|

7. Remove the camshaft pulley fixing bolt.

8. Hand tighten the timing belt auto tensioner bolts in the order A to B as indicated in the figure.

9. Tighten the timing belt auto tensioner bolts in the order A to B as indicated in the figure.

am3zzw00004168

|

10. Remove the pin from the timing belt auto tensioner to apply tension to the belt.

11. Turn the crankshaft clockwise twice, and align the timing marks.

12. Verify that all timing marks are correctly aligned.

Crankshaft Pulley Installation Note

1. Tighten the bolts in the order shown.

am3zzw00003968

|

No.3 Engine Mount Installation Note

1. Tighten the No.3 engine mount stud bolts.

am6zzw00003689

|

2. Install the No.3 engine mount rubber hand-tighten.

3. Temporarily the No.3 engine mount rubber bolts in the order as shown.

am6zzw00003128

|

4. Tighten the No.3 engine mount rubber bolts.

5. Temporarily the No.3 engine mount bracket nuts in the figure.

am6zzw00003147

|

6. Tighten the No.3 engine mount bracket bolt and nuts in the order as shown.

am6zzw00003139

|