|

COMPRESSION INSPECTION [MZR-CD 2.2]

id0110f2800300

1. Verify that the battery is fully charged. (See BATTERY INSPECTION [MZR-CD 2.2].)

2. Warm up the engine to the normal operating temperature.

3. Disconnect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION [MZR-CD 2.2].)

4. Remove the engine cover. (See ENGINE COVER REMOVAL/INSTALLATION [MZR-CD 2.2].)

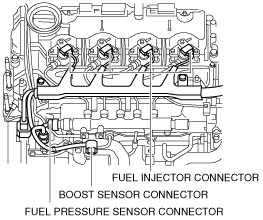

5. Disconnect the following parts.

am6zzw00004444

|

6. Remove the boost sensor and vacuum hose. (See COMMON RAIL REMOVAL/INSTALLATION [MZR-CD 2.2].)

7. Remove the EGR cooler bypass valve control solenoid valve bracket No.1. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [MZR-CD 2.2].)

8. Remove all the glow plugs. (See GLOW PLUG REMOVAL/INSTALLATION [MZR-CD 2.2].)

9. Remove the following parts to secure a sufficient space for installing the SST.

am6zzw00004313

|

10. Install the SST (49 S013 102A) to the glow plug hole securely.

11. Connect the SST (49 S010 1A0A) to SST (49 S013 102A).

am6zzw00004180

|

12. connect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION [MZR-CD 2.2].)

13. Fully depress the accelerator pedal and crank the engine.

14. Inspect each cylinder as above.

15. Disconnect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION [MZR-CD 2.2].)

16. Remove the SSTs.

17. Install in the reverse order of removal.

18. Erase DTC from PCM memory using the M-MDS. (See AFTER REPAIR PROCEDURE [MZR-CD 2.2].)