METERING OIL PUMP CONSTRUCTION/OPERATION [13B-MSP]

id0111e4661100

Construction

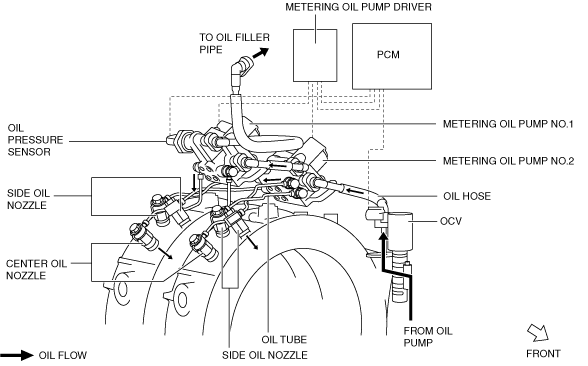

• An electric metering oil pump system has been adopted to optimally control the oil injection amount for effective oil supply and lower oil consumption.

• The electric metering oil pump consists of the metering oil pumps No.1 and No.2, center oil nozzles, side oil nozzles, oil control valve (OCV), oil pressure sensor, metering oil pump driver, PCM, oil hoses, and oil tubes.

Component parts and function

|

Part name

|

Function

|

|

Metering oil pump No.1

|

Supplies oil to the center oil nozzles

|

|

Metering oil pump No.2

|

Supplies oil to the side oil nozzles

|

|

Center oil nozzle

|

Discharges oil to the center area of the rotor housing

|

|

Side oil nozzle

|

Discharges oil to the side surface of the side housing

|

|

OCV

|

Based on the signals from the PCM, adjusts the amount of oil supplied to the metering oil pump so that the oil pressure in the metering oil pump is kept constant.

|

|

Oil pressure sensor

|

Detects oil pressure in the metering oil pump and inputs to the PCM

|

|

Metering oil pump driver

|

Supplies battery voltage to the metering oil pump based on the signals from the PCM

|

|

PCM

|

Controls the metering oil pump driver and OCV to realize the optimum oil discharge amount according to engine operation conditions

|

Metering oil pump

-

• The metering oil pump consists of the main and sub plungers, coil spring, check valve, and orifice.

• The metering oil pump No.1 supplies oil to the center oil nozzles, and the metering oil pump No.2 to the side oil nozzles.

Oil nozzle

-

• A total of three oil nozzles, one center oil nozzle and two side oil nozzles, are equipped per one rotor. The center oil nozzle discharges oil to the center area of the rotor housing, and the side oil nozzles to the side surface of the side housing. As a result, oil can be supplied to the entire rotor, enhancing the engine reliability.

• The oil nozzle consists of a check valve which opens and closes the oil passage inside the nozzle, spring, and built-in filter.

Operation

• The PCM sends drive signals to the metering oil pump driver according to the engine operation conditions. The metering oil pump driver receives the drive signals from the PCM, and switches the inner ground to supply battery voltage to the metering oil pumps No.1 and No.2.

• When the battery voltage is supplied by the metering oil pump driver, the main and sub plungers in the metering oil pump move. The plungers return to the original position by spring force when the battery voltage is not supplied.

• When the battery voltage is not supplied, oil is suctioned to the space which is made by the plunger pulled by spring force. At this point (suction stage), oil is not supplied to the oil nozzle because the check valve is closed. When the battery voltage is supplied, the plunger moves (pops out) and pushes out the suctioned oil to the oil nozzle side. Because the oil is pushed into the oil tube, the oil pressure in the oil tube increases, then the check valve in the oil nozzle is open and the oil is discharged to the housing. (discharge stage)

In this way, the plunger moves within a certain distance and oil is suctioned and discharged repeatedly.