1. Assemble in the order indicated in the table.

.

|

1

|

Upper cylinder block

|

|

2

|

Upper main bearing, thrust bearing

|

|

3

|

Crankshaft

|

|

4

|

Lower main bearing, thrust bearing

|

|

5

|

Lower cylinder block

|

|

6

|

Piston

|

|

7

|

Connecting rod

|

|

8

|

Piston pin

(See Piston Pin Assembly Note)

|

|

9

|

Snap ring

|

|

10

|

Piston ring

|

|

11

|

Piston, connecting rod

|

|

12

|

Connecting rod bearing

|

|

13

|

Connecting rod cap

|

1. Apply a continuous bead of silicone sealant to the upper cylinder block as indicated in the figure.

2. Install the lower cylinder block bolts in the order indicated in the figure.

Tightening torque

3. Push crankshaft forward and then rearward to seat the crankshaft thrust washer.

4. Tighten the lower cylinder block bolts in the order indicated in the figure in four steps.

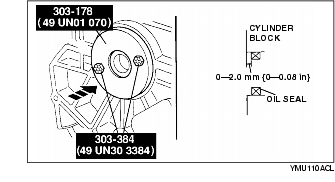

5. Assemble rear oil seal with part A of the SST [303-178 (49 UN01 070)] and the SST [303-384 (49 UN30 3384)].

1. Assemble the piston pin so that connecting rod's projection for discrimination faces opposite side of the arrow mark on the piston (rear side of the engine).

2. Apply clean engine oil to the piston pin.

3. Install the piston pin until the pin contacts the clip.

1. Install the two oil control ring segments and spacer.

2. Verify that the second ring is installed with scraper face side downward.

3. Install the top ring.

1. Position the end gap of each ring as indicated in the figure.

2. Insert the piston and connecting rod into the cylinder with the arrow mark to front of the engine.

1. Install the connecting rod bolts to the connecting rod cap by tapping the bolt with a plastic hammer.

2. Tighten the connecting rod bolts in three steps.