|

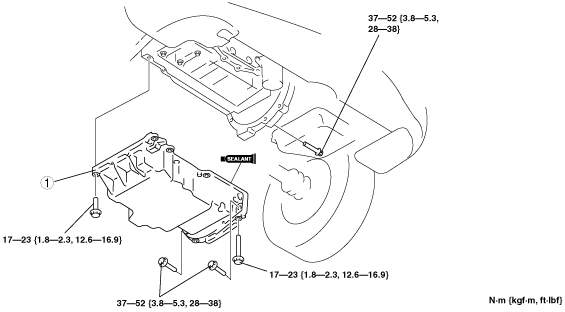

OIL PAN REMOVAL/INSTALLATION[L3]

id0111a1800200

1. Disconnect the negative battery cable.

2. Remove the front tire (RH).

3. Remove the both splash shields.

4. Drain the engine oil. (See ENGINE OIL REPLACEMENT[L3].)

5. Loosen the water pump pulley bolts before removing the drive belt.

6. Remove the drive belt. (See DRIVE BELT REMOVAL/INSTALLATION[L3].)

7. Remove the ignition coils. (See IGNITION COIL REMOVAL/INSTALLATION[L3].)

8. Remove the P/S oil pump with the hose and pipe still connected. Position the P/S oil pump out of the way. (See POWER STEERING OIL PUMP REMOVAL/INSTALLATION[L3].)

9. Remove the crankshaft position (CKP) sensor. (See CRANKSHAFT POSITION (CKP) SENSOR REMOVAL/INSTALLATION[L3].)

10. Remove the engine front cover. (See TIMING CHAIN REMOVAL/INSTALLATION[L3].)

11. Remove in the order indicated in the table.

12. Install in the reverse order of removal.

13. Refill with the specified type and amount of the engine oil. (See ENGINE OIL REPLACEMENT[L3].)

14. Start the engine and confirm that there is no oil leakage.

15. Inspect the oil level. (See ENGINE OIL LEVEL INSPECTION[L3].)

16. Inspect for the ignition timing and idle speed. (See ENGINE TUNE-UP[L3].)

atraaw00000411

|

|

1

|

Oil pan

(See Oil Pan Removal Note.)

(See Oil Pan Installation Note.)

|

Oil Pan Removal Note

1. Remove the oil pan using a separator tool.

atraaw00000412

|

Oil Pan Installation Note

atraaw00000413

|

1. Completely clean and remove any oil, dirt, sealant or other foreign material that may be adhering to the housing and oil pan.

2. When reusing the oil pan installation bolts, clean any old sealant from the bolts.

3. Use a square ruler to align the oil pan and the cylinder block junction side on the engine front cover side.

atraaw00000414

|

4. Apply silicone sealant to the oil pan along the inside of the bolt holes as shown in the figure.

atraaw00000415

|

5. Tighten the bolts in the order shown in the figure.

atraaw00000416

|

6. Tighten the oil pan-transaxle installation bolts.

atraaw00000417

|