MULTIPLEX COMMUNICATION SYSTEM CONSTRUCTION/OPERATION [L3]

BUE094055430N05

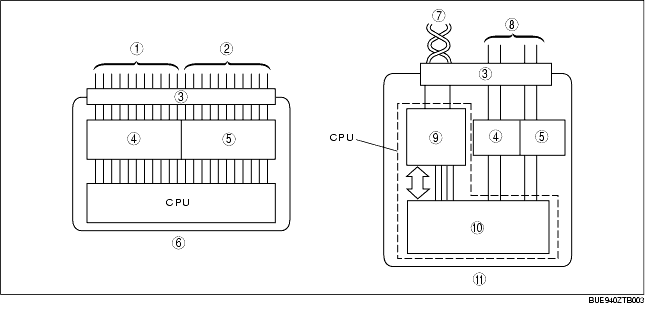

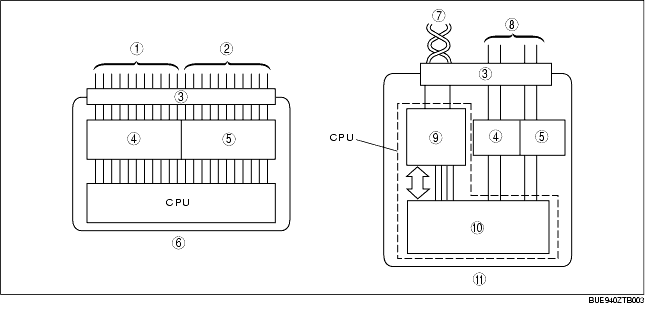

CAN System-Related Module Construction

• A CAN system-related module is composed of a power circuit, CPU, and input/output interface.

• Module size has been reduced due to the elimination of redundant parts of the input/output interface used in conventional types of electronic modules.

• The CPU (multiplex block) controls all signals exchanged via the bus lines (multiplex communication system wiring harnesses).

• Communication with non-multiplex parts is carried out using conventional input/output interface.

• The functions of each component are shown below.

|

Component

|

Function

|

|

Power circuit

|

Supplies power to CPU and vicinity, and to input/output interface.

|

|

CPU

|

Computation processing block

|

In addition to conventional CPU function, when transmission is necessary, transmitted data is stored in a multiplex block.

When the multiplex block receives a request to read stored data, transmitted data is read from the multiplex block.

|

|

Multiplex block

|

Transmits data received from bus lines to computation processing block.

In addition, sends transmitted data stored from computation processing block to bus lines.

|

|

Input interface circuit

|

Converts information signals from switches to electrical signals that can be input to CPU.

|

|

Output interface circuit

|

Converts electrical signals output from CPU for operating motors and other parts.

|

|

1

|

Input signal

|

|

2

|

Output signal

|

|

3

|

Connector

|

|

4

|

Input interface

|

|

5

|

Output interface

|

|

6

|

Conventional module

|

|

7

|

CAN harness (twisted pair)

|

|

8

|

Conventional wiring harness

|

|

9

|

Multiplex block

|

|

10

|

Computation processing block

|

|

11

|

CAN system-related module

|

Twisted Pair Construction

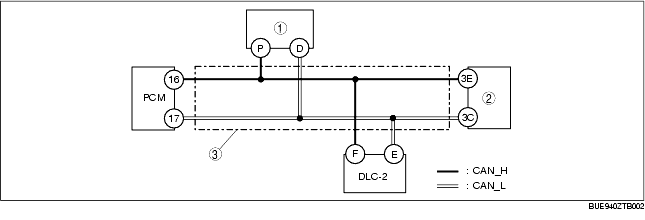

• The CAN system uses two spirally twisted wires called a twisted pair, and each wire, bus line A (CAN_L) and bus line B (CAN_H), has unique characteristics.

• Both bus lines are opposite phase voltage so that emitted noise is lessened and exterior noise interference is not easily received.

CAN System Outline

• For information exchange between electronic modules in a conventional system, separate information signals are required. However, with the CAN system, it is possible to send a large amount of information via a small wiring harness by sending multiple signals at varying times over one channel. This is referred to as time division multiplexing.

CAN System Operation

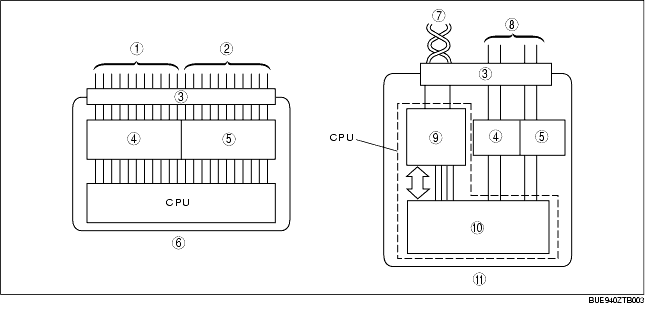

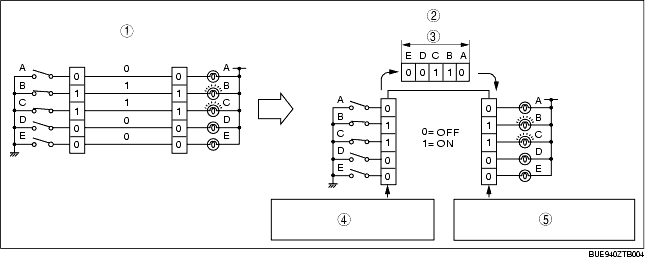

Time Division Multiplex

-

• In the conventional, non-multiplex system, in order to control the illumination of the five bulbs, one switch and one channel was necessary for each bulb. For bulbs B and C to illuminate, switches B and C must be connected and electricity must flow through each transmission channel.

-

• With the time multiplex system, this can be done through a single wire. The channel is comprised of five data signal transmitters which transmit either a "0" or "1" signal to indicate whether a bulb turns ON or OFF. For example, to illuminate bulbs B and C, transmitters B and C transmit a "1" and transmitters A, D, and E transmit a "0". When the receiver receives these signal, bulbs B and C are illuminated.

|

1

|

Non-multiplex system

|

|

2

|

Time division multiplex system

|

|

3

|

Data

|

|

4

|

Each signal is transmitted one by one through the channel as it is received.

|

|

5

|

Each signal is output one by one as it is received from the channel.

|

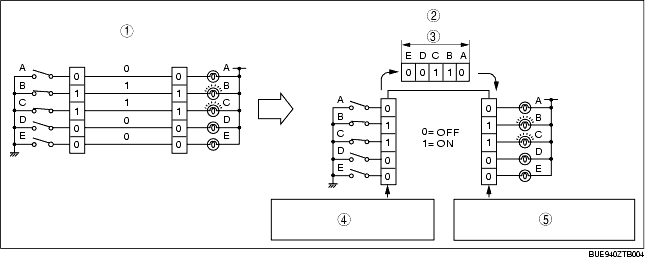

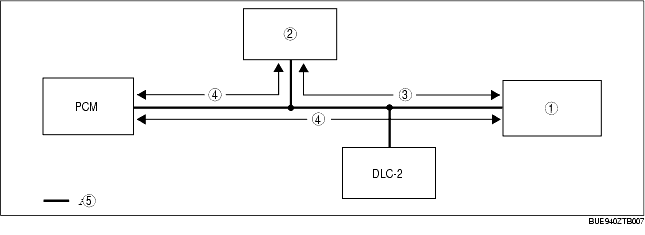

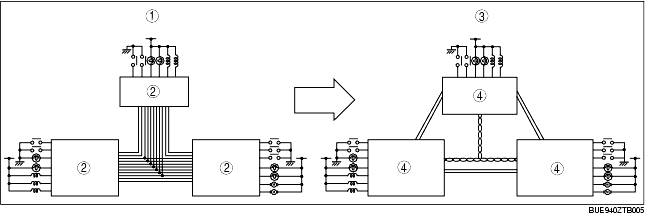

Vehicle CAN System

-

• By rearranging the multiple signal, common information between the electronic modules is transmitted and received via the twisted pairs.

-

• The signal transmitted by one CAN system-related module is sent via twisted pairs to all the CAN system-related modules, but only the corresponding module(s) receives the signal and performs the appropriate operation.

|

1

|

Conventional system

|

|

2

|

Electrical module

|

|

3

|

CAN system

|

|

4

|

CAN system-related module

|

CAN Signal Table

• Sending/receiving of CAN signals is as follows:

OUT: Output (Sends signal)

IN: Input (Receives signal)

|

Signal

|

CAN system-related module

|

|

PCM

|

ABS HU/CM

|

Instrument cluster

|

|

Engine speed

|

OUT

|

-

|

IN

|

|

Vehicle speed

|

OUT

|

-

|

IN

|

|

Brake system warning light illumination request

|

-

|

OUT

|

IN

|

|

ABS warning light illumination request

|

-

|

OUT

|

IN

|

|

ECT

|

OUT

|

-

|

IN

|

|

Distance travelled

|

OUT

|

-

|

IN

|

|

Engine warning light illumination request

|

OUT

|

-

|

IN

|

|

O/D OFF indicator light illumination request

|

OUT

|

-

|

IN

|

|

Generator warning light illumination request

|

OUT

|

-

|

IN

|

|

Wheel speed (LF, RF, LR, RR)

|

IN

|

OUT

|

-

|

|

Engine specification

|

OUT

|

IN

|

-

|

ON-BOARD DIAGNOSTIC SYSTEM OUTLINE

• CAN system-related modules have an on-board diagnostic function that is able to determine malfunction locations when there is an irregularity in the CAN system.

• The on-board diagnostic function has a malfunction detection function that detects irregularities in CAN system-related parts, a memory function that stores detected malfunctions, and a display function that displays the location and contents of malfunctions via DTC output.

• DTCs can be read out and cleared using the WDS or equivalent.

• The CAN system has a fail-safe function. When a malfunction occurs in the CAN system, the transmission module sends a warning signal, the receiving module illuminates the warning light, and the fail-safe function performs control to safeguard the system.

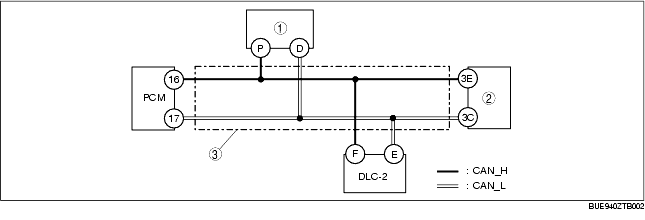

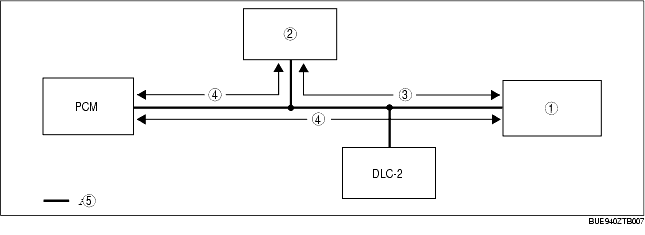

On-Board Diagnostic System Construction/Operation

Block Diagram

|

1

|

ABS HU/CM

|

|

2

|

Instrument cluster

|

|

3

|

Twisted pair

|

Malfunction detection function

-

• Detects irregularities in the input/output signals of CAN system-related modules.

-

• The DTC for the detected malfunction is output to the DLC-2, and the detected result is also sent to the memory, display, and fail-safe functions.

Fail-safe function

-

• When the malfunction detection function determines that there is an irregularity, the fail-safe function illuminates a warning light to advise the driver and controls input and output parts to allow safe driving.

Memory function

-

• Stores DTCs for malfunctions of the input/output signal system, as determined by the malfunction detection function.

Display function

-

• Outputs the signal for a malfunction determined by the malfunction detection function as a DTC to the DLC-2.

-

• DTCs can be read out using the WDS or equivalent.

DTC table

|

DTC

|

Malfunction location

|

DTC Output Unit

|

|

U0073

|

Module communication error

|

• PCM

• Instrument cluster

|

|

U0121

|

Communication error

|

PCM

|

|

U1900

|

Communication error

|

• ABS HU/CM

• Instrument cluster

|

|

U2023

|

Abnormal data

|

ABS HU/CM

|

PID/data monitor function

-

• The PID/data monitor function is used for optionally selecting input/output signal monitor items preset in the instrument cluster and reading them out in real-time.

-

• PIDs can be read out using the WDS or equivalent.

|

WDS or equivalent display

|

Status

|

Description

|

Monitor module

|

Terminal

|

|

ABS_MSG

|

Present

|

Communication circuit between ABS HU/CM and monitor module is normal

|

Instrument cluster

|

3E, 3C

|

|

Not Present

|

Communication circuit between ABS HU/CM and monitor module is not normal

|

|

PCM_MSG

|

Present

|

Communication circuit between PCM and monitor module is normal

|

|

Not Present

|

Communication circuit between PCM and monitor module is not normal

|

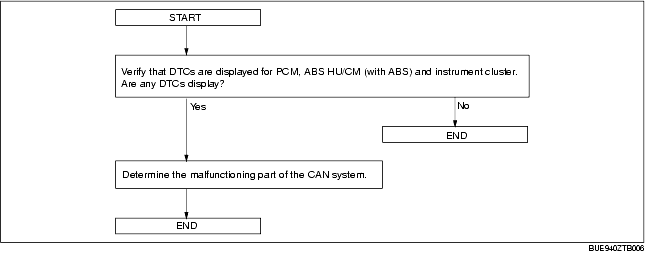

Malfunction Location Determination

-

• The on-board diagnostic function can determine CAN system malfunction locations by verifying the detected DTC information from each module.

-

• Refer to the display function for a detailed explanation of DTCs. (See Display function.)

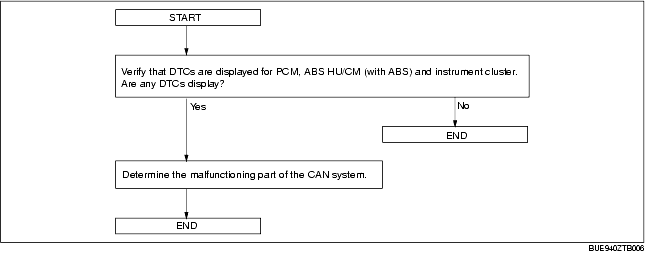

Flowchart

Example (PCM-related wiring harness open circuit)

-

Note

-

• This example applies to the PCM, ABS HU/CM, and instrument cluster.

1. DTCs for CAN system-related modules are verified using the WDS or equivalent.

|

Module

|

DTC

|

Probable malfunction location

|

|

PCM

|

U0073

|

PCM-related CAN system malfunction

|

|

U0121

|

Communication error

|

|

ABS HU/CM

|

U2523

|

Communication error

|

|

Instrument cluster

|

U1900

|

Communication error

|

2. Instrument cluster PIDs are verified using the WDS or equivalent.

|

PID

|

DTC

|

Probable malfunction location

|

|

PCM_MSG

|

Not Present

|

Communication error between the instrument cluster and the PCM

|

|

ABS_MSG

|

Present

|

Normal communication between instrument cluster and ABS HU/CM

|

|

1

|

Instrument cluster

|

|

2

|

ABS HU/CM

|

|

3

|

Communication normal

|

|

4

|

Communication error

|

|

5

|

Twisted pair

|

3. If there is a communication error between the instrument cluster and PCM, even if the communication between the DSC HU/CM and the instrument cluster is normal, it is probable that there is a malfunction in the PCM or PCM-related wiring harnesses.