1. Verify the customer's concern by operating the engine to duplicate the condition.

2. Inspect to determine if any of the following mechanical concerns apply:

Visual Inspection Chart

|

Mechanical

|

|---|

|

• Drive belt cracking/chunking/wear

• Drive belt noise or squeal

• Pulley misalignment or excessive pulley runout

|

3. Install a new drive belt if any of the following conditions exist: rib chunk-out, severe glazing, frayed cords or other concerns.

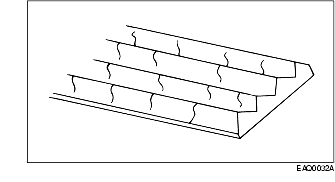

Inspect for drive belt cracking/chunking/wear.

V-ribbed serpentine drive belt with chunks of rib missing

The only mechanical check that needs to be made is a check for tensioner stick, grab or bind.

1. Remove the belt in the area of the tensioner.

2. Rotate the tensioner from its relaxed position through its full stroke and back to the relaxed position to make sure there is no stick, grab or bind and to make sure that there is tension on the belt tensioner spring.

3. If the tensioner meets the above criteria, proceed to test the tensioner dynamically. If the tensioner does not meet the above criteria, install a new tensioner. (See DRIVE BELT REPLACEMENT [YF (2.0L Zetec)].)

The belt tensioner can be checked dynamically as follows:

1. With the engine running, observe the belt tensioner movement. The belt tensioner should move (respond) when the A/C clutch cycles (if equipped), or when the engine is accelerated rapidly. If the belt tensioner movement is constant without A/C clutch cycling or acceleration, a pulley or shaft is probably bent or a pulley is out of round. In rare cases, excessive drive belt rideout (uneven depth of grooves in drive belt) can cause excessive drive belt tensioner movement. This condition can be checked by installing a new drive belt, and repeating the observation.

2. With the engine off, check routing of the drive belt.

3. Inspect the belt tensioner wear indicator to confirm the drive belt is within operating range. Install a new drive belt if necessary. (See DRIVE BELT REPLACEMENT [YF (2.0L Zetec)].)