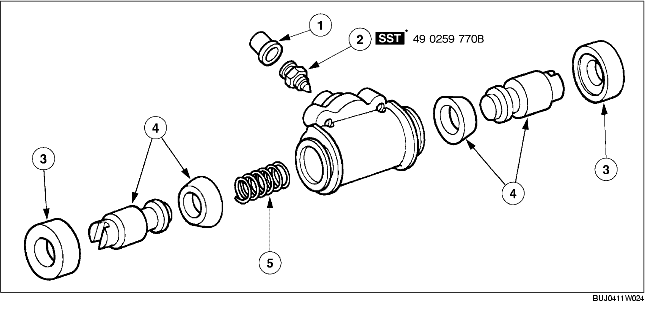

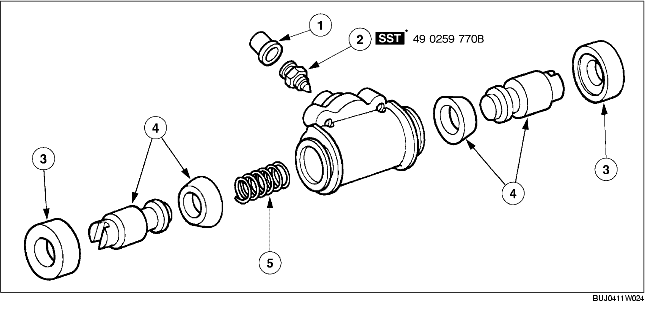

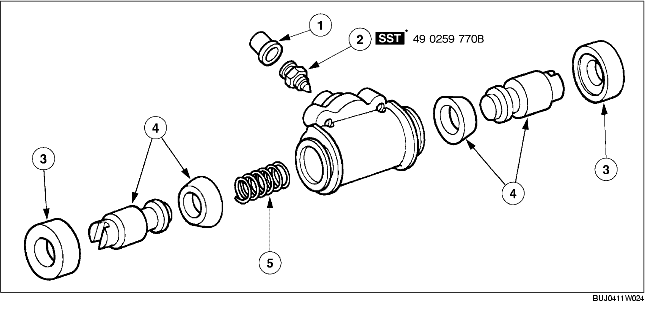

WHEEL CYLINDER DISASSEMBLY/ASSEMBLY

id041100811100

1. Remove the wheel cylinder. (See WHEEL CYLINDER REMOVAL/INSTALLATION.)

2. Disassemble the wheel cylinder.

-

Caution

-

• Do no use denatured alcohol for flushing the brake system or cleaning components where alcohol could be trapped. If denatured alcohol is trapped, it can cause eventual failure of rubber components in the system.

-

• Never allow any petroleum product or mineral oil to contact the inside of a brake system. Mineral oil and petroleum products deteriorate the natural rubber seals used in brake systems. If a brake system becomes contaminated, it must be flushed with clean brake fluid and all rubber seals and hoses replaced. Use specified brake fluid.

-

(1) Remove the bleeder cap.

-

(2) Remove the bleeder screw.

-

(3) Remove the boots.

-

(4) Remove the wheel cylinder pistons and piston cups.

-

(5) Remove the wheel cylinder spring.

3. Inspect the wheel cylinder for wear, rust or pits. If any of these conditions exist, replace the wheel cylinder.

4. Assemble in the reverse order of disassembly.

-

Caution

-

• Always install new piston cups and boots when assembling the wheel cylinder. Lubricate the bore with new brake fluid. Use specified brake fluid.