MECHANICAL SYSTEM TEST [LA4AX-EL (CD4E)]

id0517a5802100

Mechanical System Test Preparation

1. Engage the parking brake and use wheel chocks at the front and rear of the wheels.

2. Inspect the engine coolant level. (See COOLING SYSTEM SERVICE WARNINGS.) (See ENGINE COOLANT LEVEL INSPECTION.)

3. Inspect the engine oil level. (See ENGINE OIL LEVEL INSPECTION.)

4. Inspect the ATF level. (See Automatic Transaxle Fluid (ATF) Level Inspection.)

5. Inspect the ignition timing. (See IGNITION TIMING INSPECTION.)

6. Inspect the idle speed. (See IDLE SPEED INSPECTION.)

Line Pressure Test

-

Warning

-

• Removing the square head plug when the ATF is hot is dangerous. Hot ATF can discharge from the opening and cause severe burns. Before removing the square head plug, allow the ATX and ATF to cool.

-

Caution

-

• Perform the line pressure test before performing the stall test. If the line pressure is low at stall speed, do not perform the stall test or further transaxle damage will occur.

-

• Do not maintain WOT in any gear position for more than 5 s.

-

• The transmission tester must be removed from the transaxle and connected to the vehicle wiring harness verify these pressures.

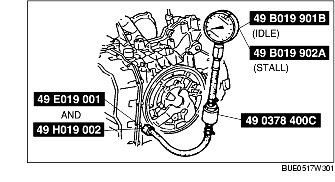

1. Remove the line pressure square head plug and connect the SST (49 0378 400C).

-

• When measuring while idling, replace the SST (49 B019 901B) with the SST gauge (49 0378 400C).

-

• When measuring at stall, replace the SST (49 B019 902A) with the SST gauge (49 0378 400C).

2. Start the engine and inspect the line pressures.

-

• If the line pressure is not within the specification, inspect according to "ON-BOAD DIAGNOSIS" and "SYMPTOM TROUBLESHOOTING".

Line pressure

|

Position/range

|

Line pressure (kPa {kgf/cm2, psi})

|

|

Idle

|

Stall

|

|

P/N

|

441-524 {4.5-5.3, 64-75}

|

-

|

|

R

|

441-524 {4.5-5.3, 64-75}

|

1,786-2,027 {18.3-20.6, 259-293}

|

|

D

|

324-372 {3.3-3.7, 47-53}

|

1,158-1,269 {11.8-12.9, 168-184}

|

|

2

|

324-372 {3.3-3.7, 47-53}

|

1,158-1,269 {11.8-12.9, 168-184}

|

|

1

|

324-372 {3.3-3.7, 47-53}

|

1,158-1,269 {11.8-12.9, 168-184}

|

-

Warning

-

• Removing the SSTs when the ATF is hot is dangerous. Hot ATF can discharge from the opening and cause severe burns. Before removing the SSTs, allow the ATF to cool.

3. Stop the engine and remove the SSTs.

-

Note

-

• The square head plug cannot be reused because it has coating on it.

4. Install a new square head plug.

Line Pressure Diagnosis

1. If the line pressure is low at idle in each shift position inspect the following:

-

• Low ATF level

-

• Restricted inlet filter

-

• Loose main body

-

• Solenoid body or accumulator body to case bolts

-

• Excessive leakage in pump

-

• Case

-

• Control body

-

• Stuck main regulator valve or damaged inlet tube seal on inlet filter

-

• Damaged gasket or separator plate

2. If the line pressure is high at idle in each shift position inspect the following:

-

• Main regulator valve

-

• Solenoid body and wiring harness

Stall Speed Test

-

Warning

-

• Apply the parking brake firmly while performing each stall test. Failure to set brakes can result in death or severe injury.

-

Caution

-

• Perform the line pressure test before performing the stall test. If the line pressure is low at stall speed, do not perform the stall test or further transaxle damage will occur.

-

• The stall test should only be performed with the engine and transaxle at normal operating temperature.

-

Note

-

• The stall speed test inspects the operation of the following:

-

- Torque converter one-way clutch

-

- Forward clutch

-

- Low/reverse one-way clutch

-

- Reverse clutch

-

- Forward one-way clutch

-

- Engine performance

1. Connect a tachometer to the engine.

-

Caution

-

• Do not maintain WOT in any shift position for more than 5 s.

-

• If the engine rpm recorded by the tachometer exceeds the maximum specified rpm, release the accelerator pedal immediately. Otherwise, clutch or band slippage could occur.

2. Depress the accelerator pedal to floor (WOT) in each shift position. Record rpm reached in each shift position.

Engine stall speed

|

Engine type

|

rpm

|

|

AJ (3.0L Duratec)

|

2,586-2,963

|

3. After testing the D range and R position, shift the selector lever to the N position and run the engine for 15 s to allow the torque converter to cool before testing the next gear position.

4. If the stall speed is too high, refer to the stall speed diagnosis chart.

Stall speed diagnosis chart

|

Position/range

|

Possible cause

|

|

D, 2, 1

|

• Forward clutch

• Forward one-way clutch

• Low one-way clutch

|

|

R

|

• Reverse clutch

• Low/Reverse clutch

|

5. If the stall speed is too low, inspect the idle speed.

-

• If the idle speed is normal, remove the torque converter and inspect the torque converter one-way clutch for slippage.