Rear

WHEEL ALIGNMENT1. Measure vehicle height.

NOTICE: Before inspecting the wheel alignment, adjust the vehicle height to specification.

If the vehicle height is not to the specification, try to adjust it by pushing down on or lifting the body.

2. Install camber-caster-kingpin gauge or onto wheel alignment tester.

Follow the specifications of the equipment manufacturer.

3. Inspect camber.

Camber: -1° 20' ± 45' (-1.33° ± 0.75°)

Left-Right error: 45' (0.75°) or less

If the camber is not within the specification, adjust it by the camber adjust cam.

Measuring Point Reference:

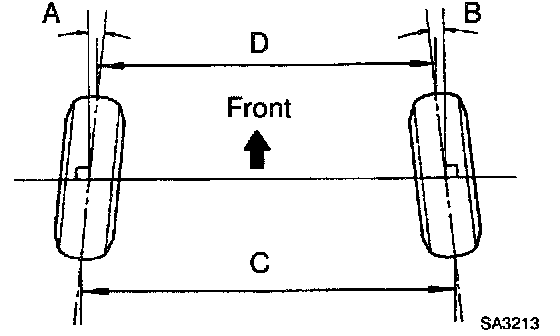

4. Inspect toe-in.

Toe-in (Total):

A + B: 0° 20' ± 0° 10' (0.33° ± 0.17°)

C - D: 4 ± 2 mm (0.16 ± 0.08 inch)

If the toe-in is not within the specification, adjust it by the toe-adjust cam.

5. Adjust camber.

a. Loosen the camber adjust cam lock bolt.

b. Turn the camber adjust cam to adjust camber.

HINT:

^ Try to adjust the camber to the center value.

^ The camber will change about 16' (0.27°) with each graduation of the cam.

c. Torque the lock bolt.

Torque: 113 Nm (83 ft. lbs.)

6. Adjust toe-in.

a. Measure the distance between each wheel disc and corner of the cam bracket, then confirm that both are the same.

No. 2 lower suspension arm length difference: 1 mm (0.04 inch) or less

If the left-right difference is greater than 1 mm (0.04 inch), adjust it by following the procedures below.

b. Loosen the toe-adjust cam lock bolt.

c. Turn the toe-adjust cam an equal amount to adjust toe-in.

HINT:

^ Try to adjust the toe-in to the center value.

^ The toe-in will change about 2.5 mm (0.10 inch) with each graduation of the cam (both side).

d. Torque the lock bolts.

Torque: 132 Nm (97 ft. lbs.)