Oil Pump

OIL PUMP

Components

Oil Pump Disassembly

1. REMOVE OIL SEAL RINGS

Remove the 2 oil seal rings from the stator shaft back side.

2. REMOVE THRUST WASHER FROM STATOR SHAFT BACK SIDE

3. REMOVE STATOR SHAFT

Remove the 11 bolts and stator shaft. Keep the gears in assembly order.

4. REMOVE FRONT OIL SEAL

Pry off the oil seal with a screwdriver.

Oil Pump Bushing Inspection

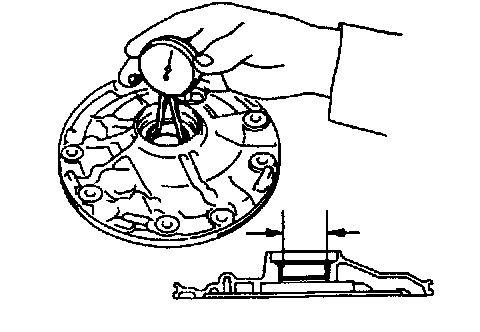

1. CHECK BODY CLEARANCE OF DRIVEN GEAR

Push the driven gear to one side of the body. Using a feeler gauge, measure the clearance.

Standard body clearance: 0.07 - 0.15 mm (0.0028 - 0.0059 inch)

Maximum body clearance: 0.3 mm (0.012 inch)

If the body clearance is greater than the maximum, replace the oil pump body subassembly.

2. CHECK TIP CLEARANCE OF DRIVEN GEAR

Measure between the driven gear teeth and the crescent-shaped part of the pump body.

Standard tip clearance: 0.11 - 0.14 mm (0.0043 - 0.0055 inch)

Maximum tip clearance: 0.3 mm (0.012 inch)

If the tip clearance is greater than the maximum, replace the oil pump body subassembly.

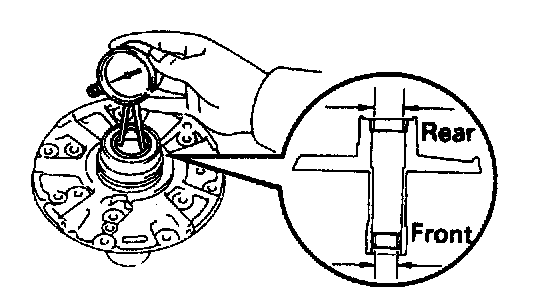

3. CHECK SIDE CLEARANCE OF BOTH GEARS

Using a steel straightedge and a feeler gauge, measure the side clearance of both gears.

Standard side clearance: 0.02 - 0.05 mm (0.0008 - 0.0020 inch)

Maximum side clearance: 0.1 mm (0.004 inch)

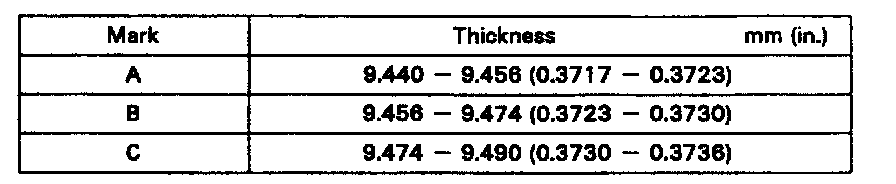

There are 3 different thicknesses for drive and driven gears.

Drive And Driven Gear Thickness

If the thickest gear cannot make the side clearance within standard specification, replace the oil pump body subassembly.

4. CHECK OIL PUMP BODY BUSHING

Using a dial indicator, measure the inside diameter of the oil pump body bushing.

Maximum Inside diameter: 38.18 mm (1.5031 inch)

If the inside diameter is greater than the maximum, replace the oil pump body subassembly.

5. CHECK STATOR SHAFT BUSHINGS

Using a dial indicator, measure the inside diameter of the stator shaft bushings.

Maximum inside diameter:

Front side: 21.57 mm (0.8492 inch)

Rear side: 27.07 mm (1.0657 inch)

If the inside diameter is greater than the maximum, replace the stator shaft.

Oil Pump Assembly

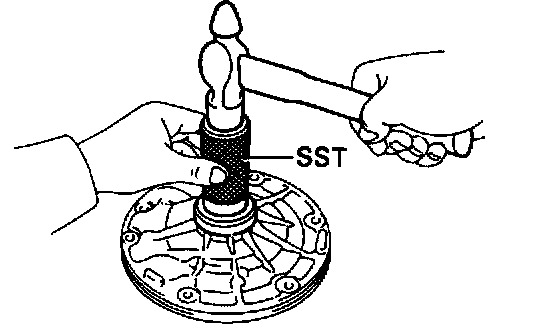

1. INSTALL FRONT OIL SEAL

Using Special Service Tools (SST) and a hammer, install a new oil seal. The seal end should be flush with the outer edge of the pump body.

SST 09350-32014 (09351-32140)

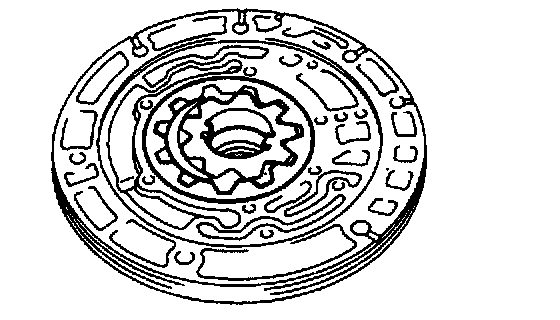

2. INSTALL DRIVEN GEAR AND DRIVE GEAR

Make sure the top of the gears are facing upward.

3. INSTALL STATOR SHAFT ONTO PUMP BODY

Align the stator shaft with each bolt hole.

4. TIGHTEN 11 STATOR SHAFT BOLTS

Torque: 10 Nm (100 kgf.cm, 7 ft. lbs.)

5. INSTALL THRUST WASHER

a. Coat the thrust washer with petroleum jelly.

b. Align the tab of the washer with the hollow of the pump body.

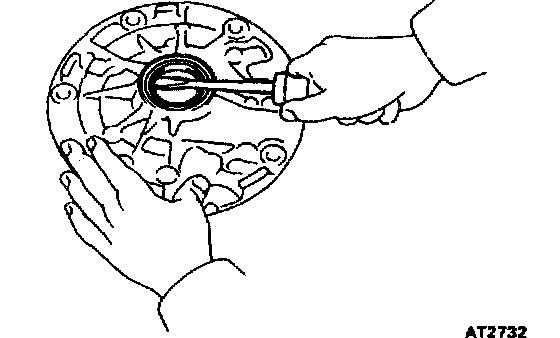

6. INSTALL 2 OIL SEAL RINGS ON OIL PUMP

Install 2 oil seal rings to the stator shaft groove, then snug them down by squeezing their ends together.

NOTICE: Do not spread the ring ends too much.

HINT: After installing the oil seal rings, check that they move smoothly.

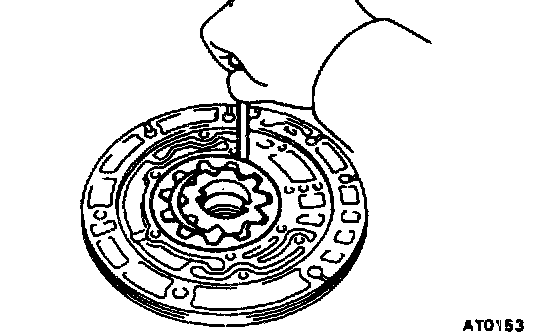

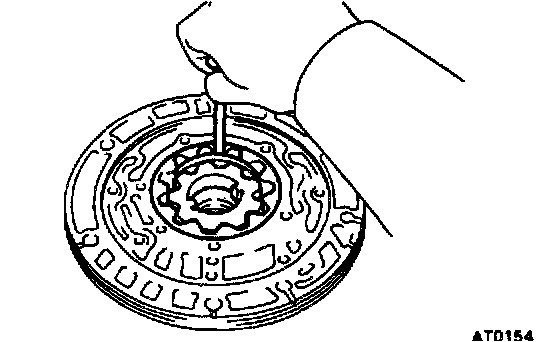

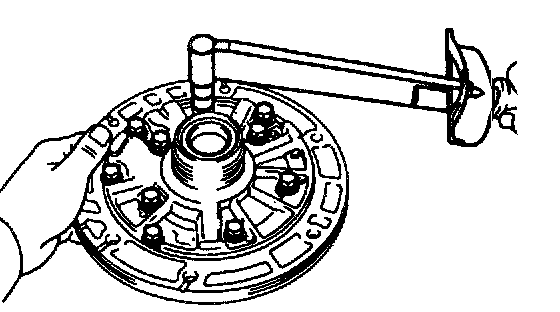

7. CHECK PUMP DRIVE GEAR ROTATION

Turn the drive gear with screwdrivers and make sure that it rotates smoothly.

NOTICE: Be careful not to damage the oil seal lip.