Oil Pump Replace

REMOVAL

HINT: When repairing the oil pump, the oil pan and strainer should be removed and cleaned.

1. DRAIN ENGINE OIL

2. REMOVE ENGINE UNDER COVERS

3. REMOVE FRONT EXHAUST PIPE

4. REMOVE ENGINE MOUNTING CENTER MEMBER

5. REMOVE TWC (FRONT)

a. Disconnect the oxygen sensor (bank 1 sensor 2) connector.

b. Remove the 2 bolts, 2 nuts and RH exhaust manifold stay.

c. Remove the 3 bolts, 2 nuts, TWC, gasket, retainer and cushion.

6. REMOVE REAR END PLATE STIFFENER

a. Remove the bolt, nut and intake manifold stay.

b. Remove the 6 bolts and plate stiffener.

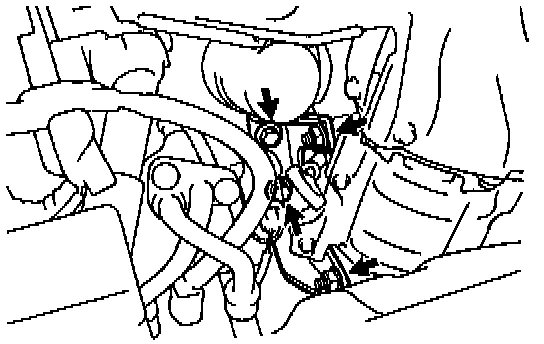

7. REMOVE OIL PAN

a. Remove the oil dipstick.

b. Remove the 17 bolts and 2 nuts

c. Insert the blade of Special Service Tool (SST) between the cylinder block and oil pan, and cut off applied sealer and remove the oil pan.

SST 09032-00100

NOTICE:

^ Do not use SST for the oil pump body side and rear oil seal retainer.

^ Be careful not to damage the oil pan flange.

8. REMOVE OIL STRAINER AND OIL PAN BAFFLE PLATE

Remove the 2 bolts, 2 nuts, oil strainer, baffle plate and gasket.

9. SUSPEND ENGINE WITH ENGINE SLING DEVICE

10. REMOVE TIMING BELT

11. REMOVE NO.2 IDLER PULLEY

Remove the bolt and idler pulley

12. REMOVE CRANKSHAFT TIMING PULLEY

13. REMOVE OIL PUMP PULLEY

14. REMOVE OIL PUMP

Remove the 12 bolts, oil pump and gasket.

INSTALLATION

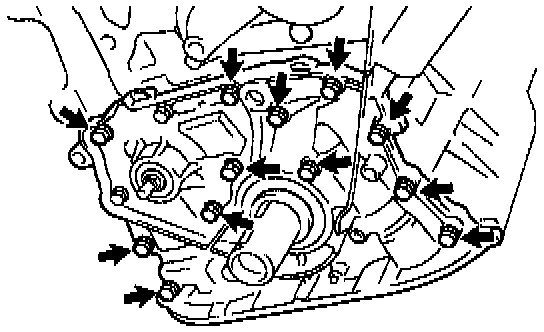

1. INSTALL OIL PUMP

Install a new gasket and the oil pump with the 12 bolts. Uniformly tighten the bolts in several passes.

Torque: 8.8 Nm (90 kgf-cm, 78 inch lbs.)

HINT: Each bolt length is indicated in the illustration.

Bolt length:

25 mm (0.98 inch) for A

35 mm (1.38 inch) for B

2. INSTALL OIL PUMP PULLEY

3. INSTALL CRANKSHAFT TIMING PULLEY

4. INSTALL NO.2 IDLER PULLEY

5. INSTALL TIMING BELT

6. REMOVE ENGINE SLING DEVICE

7. INSTALL OIL PAN BAFFLE PLATE AND OIL STRAINER

Install a new gasket, the oil strainer and baffle plate with the 2 bolts and 2 nuts.

Torque: 5.4 Nm (55 kgf-cm, 48 inch lbs.)

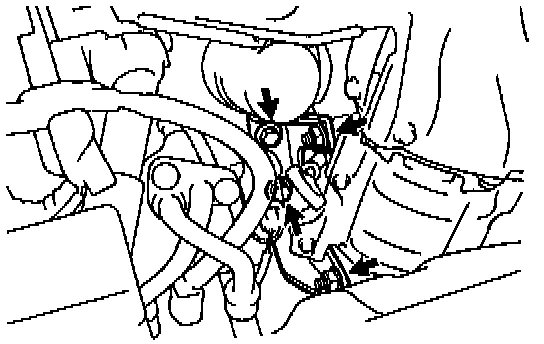

8. INSTALL OIL PAN

a. Remove any old packing Formed In Place Gasket (FIPG) material and be careful not to drop any oil on the contact surfaces of the oil pan and cylinder block.

^ Using a razor blade and gasket scraper, remove all the old packing (FIPG) material from the gasket surfaces and sealing groove.

^ Thoroughly clean all components to remove all the loose material.

^ Using a non-residue solvent, clean both sealing surfaces.

NOTICE: Do not use a solvent which will affect the painted surfaces.

b. Apply seal packing to the oil pan as shown in the illustration.

Seal packing:

Part No. 08826-00080 or equivalent

^ Install a nozzle that has been cut to a 3 - 5 mm (0.12 - 0.20 inch) opening.

^ Parts must be assembled within 5 minutes of application. Otherwise the material must be removed and reapplied.

^ Immediately remove nozzle from the tube and reinstall cap.

c. Install the oil pan with the 17 bolts and 2 nuts. Uniformly tighten the bolts and nuts in several passes.

Torque: 5.4 Nm (55 kgf-cm, 48 inch lbs.)

d. Install the dipstick.

9. INSTALL REAR END PLATE STIFFENER

a. Install the plate stiffener with the 6 bolts. Alternately tighten the bolts in several passes.

Torque:

12 mm head 21 Nm (210 kgf-cm, 15 ft. lbs.)

14 mm head 44 Nm (440 kgf-cm, 32 ft. lbs.)

b. Install the intake manifold stay with the bolt and nut.

Torque:

Bolt 21 Nm (210 kgf-cm, 15 ft. lbs.)

Nut 44 Nm (440 kgf-cm, 32 ft. lbs.)

10. INSTALL FRONT TWC

a. Place the cushion, retainer and a new gasket on the TWC.

b. Install the Three-Way Catalytic Converter (TWC) with the 3 bolts and 2 nuts.

Torque: 29 Nm (300 kgf-cm, 21 ft. lbs.)

c. Install the RH exhaust manifold stay with the 2 bolts and 2 new nuts.

Torque: 42 Nm (425 kgf-cm, 31 ft. lbs.)

d. Connect the oxygen sensor (bank 1 sensor 2) connector.

11. INSTALL ENGINE MOUNTING CENTER MEMBER

12. INSTALL FRONT EXHAUST PIPE

13. FILL WITH ENGINE OIL

14. START ENGINE AND CHECK FOR OIL LEAKS

15. RECHECK ENGINE OIL LEVEL

16. INSTALL ENGINE UNDER COVERS