Removal

Engine Compartment Components:

Alternator, Ignition System, And Exhaust Manifold:

Intake, EGR, Injectors:

Valve Cover, Camshafts, And Cylinder Head:

REMOVAL

1. DRAIN ENGINE COOLANT

2. REMOVE AIR CLEANER CAP

3. REMOVE GENERATOR

4. REMOVE EXHAUST MANIFOLD

a. Remove the 3 nuts holding the front exhaust pipe to the exhaust manifold.

b. Remove the 3 (California) or 5 (Except California) bolts and No.1 exhaust manifold heat insulator.

c. Remove the 2 bolts and No.1 exhaust manifold stay.

d. TMC Made: Remove the 2 nuts and No.2 exhaust manifold stay.

e. TMMK Made: Remove the bolt, nut and No.2 exhaust manifold stay.

f. Remove the wire clamp.

g. California: Disconnect the A/F sensor connector.

h. Except California: Disconnect the oxygen sensor (bank 1 sensor 1) connector.

i. Remove the 6 nuts, the exhaust manifold, No.2 and No.3 exhaust manifold heat insulators assembly.

j. California: Disconnect the A1F sensor connector for the wiring side from the bracket on the LH engine hanger.

k. Except California: Disconnect the heated oxygen sensor (bank 1 sensor 1) connector for the wiring side from the bracket on the LH engine hanger.

5. REMOVE THROTTLE BODY

6. REMOVE IGNITION COILS, NO.2 INTAKE MANIFOLD STAY AND HIGH-TENSION CORDS ASSEMBLY

a. Disconnect the 2 ignition coil connectors.

b. Disconnect the 4 high-tension cords from the 2 clamps on the cylinder head cover.

c. Disconnect the 4 high-tension cords from the spark plugs.

d. Disconnect the wire clamp from the manifold stay.

e. TMC Made: Remove the 2 nuts, 2 bolts, 2 ignition coils, manifold stay and 4 high-tension cords assembly.

f. TMMK Made: Remove the nut, 3 bolts, 2 ignition coils, manifold stay and 4 high-tension cords assembly.

7. DISCONNECT OIL PRESSURE SWITCH CONNECTOR

8. DISCONNECT NOISE FILTER CONNECTOR

9. REMOVE WATER OUTLET

a. Disconnect the ECT sensor connector.

b. Disconnect the ECT sender gauge connector.

c. Disconnect the radiator hose from the water outlet.

d. Disconnect the water bypass pipe hose from the water outlet.

e. Disconnect the heater water hose from the water outlet.

f. Remove the 2 nuts, water outlet and gasket.

10. REMOVE INTAKE MANIFOLD STAY

Remove the bolt, nut and intake manifold stay.

11. REMOVE EGR VALVE AND VACUUM MODULATOR

a. Disconnect the VSV connector for the EGR.

b. Disconnect the hose clamp from the bracket on the intake manifold.

c. Remove the bolt, and disconnect the VSV for EGR from the intake manifold.

d. Loosen the union nut of the EGR pipe, and remove the bolt, 2 nuts, the EGR valve, vacuum modulator, vacuum hoses assembly and gasket.

12. DISCONNECT ENGINE WIRE FROM INTAKE MANIFOLD

a. Disconnect the engine wire clamp from the bracket on the LH side of the intake manifold.

b. Disconnect the 2 engine wire clamps from the 2 brackets on the front side of the intake manifold.

13. DISCONNECT FUEL INLET HOSE FROM DELIVERY PIPE

a. Using Special Service Tool (SST), loosen the fuel pulsation damper.

(SST) 09612-24014 (09617-24011)

b. Remove the fuel pulsation damper and 2 gaskets, and disconnect the fuel inlet hose from the delivery pipe.

14. REMOVE INTAKE MANIFOLD

a. Disconnect the MAP sensor vacuum hose from the gas filter.

b. Disconnect the brake booster vacuum hose from the intake manifold.

c. Disconnect the PCV hose from the intake manifold.

d. Remove the 2 bolts, and disconnect the 2 ground wires from the intake manifold.

e. Disconnect the knock sensor 1 connector.

f. Remove the 6 bolts, 2 nuts, intake manifold and gasket.

15. REMOVE DELIVERY PIPE AND INJECTORS

a. Disconnect the 4 injector connectors.

b. Remove the 2 bolts and delivery pipe together with the 4 injectors.

NOTICE: Be careful not to drop the injectors when removing the delivery pipe.

c. Remove the 4 insulators (except California) and 2 spacers from the cylinder head.

d. Pull out the 4 injectors from the delivery pipe.

e. California: Remove the 2 O-rings, insulator and grommet from each injector.

f. Except California: Remove the O-ring and grommet from each injector.

16. DISCONNECT TIMING BELT FROM CAMSHAFT TIMING PULLEY

17. REMOVE CAMSHAFT TIMING PULLEY

18. REMOVE NO.1 IDLER PULLEY AND TENSION SPRING

Remove the bolt, pulley and tension spring.

19. REMOVE NO.3 TIMING BELT COVER

Remove the 3 bolts and timing and cover.

NOTICE:

- Support the timing belt, so the meshing of the crankshaft timing pulley and timing belt does not shift.

- Be careful not to drop anything inside the timing belt cover.

- Do not allow the belt to come into contact with oil, water or dust.

20. REMOVE ENGINE HANGERS AND GENERATOR BRACKET

a. Remove the 3 bolts, the generator bracket and RH engine hanger assembly.

b. Remove the bolt and LH engine hanger.

21. REMOVE OIL PRESSURE SWITCH

22. REMOVE CYLINDER HEAD COVER

Remove the 4 nuts, grommets, head cover and gasket.

HINT: Arrange the grommets in the correct order, so that they can be reinstalled into their original positions. This minimizes any possibility of oil leakage due to reuse of the grommets in different positions.

23. REMOVE CAMSHAFTS

NOTICE: Since the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being removed. If the camshaft is not kept level, the portion of the cylinder head receiving the shaft thrust may crack or be damaged, causing the camshaft to seize or break. To avoid this, the following steps should be carried out.

a. Remove the exhaust camshaft.

1) Set the knock pin of the intake camshaft at 10 - 45° BTDC of camshaft angle.

HINT: The above angle allows No.2 and No.4 cylinder cam lobes of the exhaust camshaft to push their valve lifters evenly.

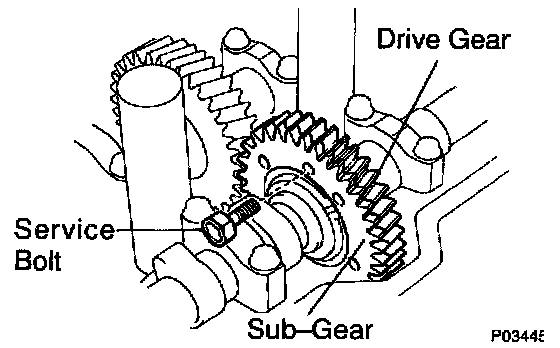

2) Secure the exhaust camshaft sub-gear to drive gear with a service bolt.

Recommended service bolt:

Thread diameter 6 mm

Thread pitch 1.0 mm

Bolt length 16 - 20 mm (0.63 - 0.79 inch)

HINT: When removing the camshaft, make sure that the torsional spring force of the sub-gear has been eliminated by the above operation.

3) Remove the 2 bolts and rear bearing cap.

4) Uniformly loosen and remove the 6 bolts on the No.1, No.2 and No.4 bearing caps in several passes, in the sequence shown.

NOTICE: Do not remove the No.3 bearing cap bolts at this stage.

5) Remove the No.1, No.2 and No.4 bearing caps.

6) Alternately loosen and remove the 2 bolts on the No.3 bearing cap.

HINT:

- As the 2 No.3 bearing cap bolts are loosened, make sure that the camshaft is lifted out straight and level.

- If the camshaft is not being lifted out straight and level, retighten the 2 No.3 bearing cap bolts. Then reverse the order of above steps from 6. to 1. and reset the knock pin of the intake camshaft at 10 - 45° BTDC, and repeat steps from 2. to 6. once again.

NOTICE: Do not pry on or attempt to force the camshaft with a tool or other object.

7) Remove the No.3 bearing cap and exhaust camshaft.

b. Remove the intake camshaft.

1) Set the knock pin of the intake camshaft at 80 - 115° BTDC of camshaft angle.

HINT: The above angle allows the No.1 and No.3 cylinder cam lobes of intake camshaft to push their valve lifters evenly.

2) Remove the 2 bolts, front bearing cap and oil seal.

3) Uniformly loosen and remove the 6 bolts on the No.1, No.3 and No.4 bearing caps in several passes, in the sequence shown.

NOTICE: Do not remove the No.2 bearing cap bolts at this stage.

4) Remove the No.1, No.3 and No.4 bearing caps.

5) Alternately loosen and remove the 2 bolts on the No.2 bearing cap.

HINT:

- As the 2 No.2 bearing cap bolts are loosened, make sure that the camshaft is lifted out straight and level, after breaking adhesion on the front bearing cap.

- If the camshaft is not being lifted out straight and level, retighten the 2 No.2 bearing cap bolts. Reverse the order of above steps from 5. to 1. and reset the knock pin of the intake camshaft at 80 - 115° BTDC, and repeat steps from 2. to 5. once again.

NOTICE: Do not pry on or attempt to force the camshaft with a tool or other object.

6) Remove the No.2 bearing cap and camshaft.

24. DISASSEMBLE EXHAUST CAMSHAFT

a. Mount the camshaft in a vise.

NOTICE: Be careful not to damage the camshaft.

b. Using SST, turn the sub-gear clockwise, and remove the service bolt.

SST 09960-10010 (09962-01000, 09963-00500)

c. Using snap ring pliers, remove the snap ring.

d. Remove the wave washer, camshaft sub-gear and gear spring.

25. REMOVE CYLINDER HEAD

a. Disconnect the camshaft position sensor connector.

b. Remove the 2 bolts holding the water bypass pipe to the cylinder head.

Cylinder Head Removal:

c. Uniformly loosen and remove the 10 cylinder head bolts in several passes, in the sequence shown.

NOTICE: Cylinder head warpage or cracking could result from removing bolts in incorrect order.

d. Lift the cylinder head from the dowels on the cylinder block, and place the cylinder head on wooden blocks on a bench.

HINT: If the cylinder head is off, pry between the cylinder head and cylinder block with a screwdriver.

NOTICE: Be careful not to damage the contact surfaces of the cylinder head and cylinder block.