Alignment: Service and Repair

NOTICE: For Zero Point Calibration information, please refer to: TSB T-SB-0020-8 (3/25/08).NOTE:

RZN161L: 4WD Regular Cab, Short Wheelbase with 3RZ-FE engine

RZN171L: 4WD Extra Cab, Extra Long Wheelbase with 3RZ-FE engine

RZN191L: 2WD PreRunner Regular Cab, Short Wheelbase with 3RZ-FE engine

RZN196L: 2WD PreRunner Extra Cab, Extra Long Wheelbase with 3RZ-FE engine

VZN170L: 4WD Extra Cab, Extra Long Wheelbase with 5VZ-FE engine

VZN195L: 2WD PreRunner Extra Cab, Extra Long Wheelbase with 5VZ-FE engine

INSPECTION

HINT: PreRunner is the model described below.

RZN191L-TRPDKAB, RZN196L-CRPDKAB, VZN195L-CRPDKAB

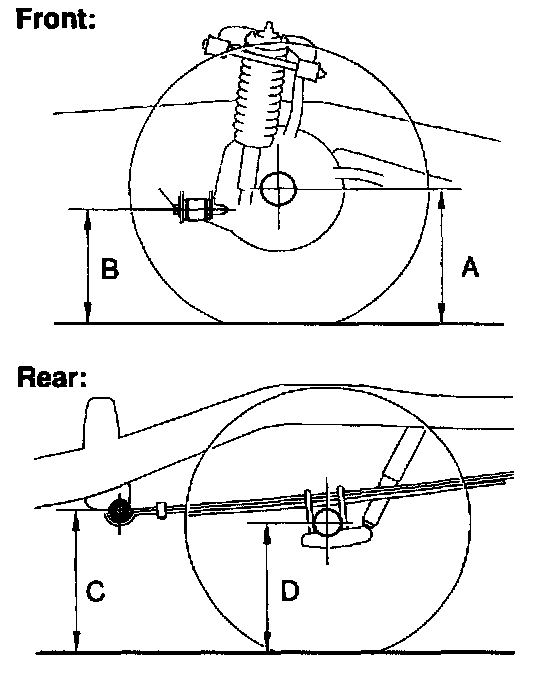

1. MEASURE VEHICLE HEIGHT

Vehicle Height:

Measuring points:

A: Ground clearance of spindle center.

B: Ground clearance of front adjusting cam bolt center.

C: Ground clearance of leaf spring front hanger pin bolt center.

D: Ground clearance of rear axle shaft center.

NOTICE: Before inspecting the wheel alignment, adjust the vehicle height to the specified value. If the vehicle height is not the specified value, try to adjust it by pushing down on or lifting the body.

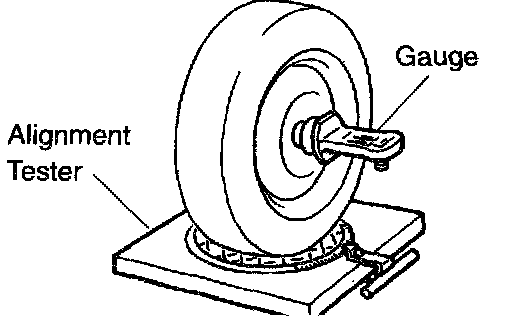

2. INSTALL CAMBER-CASTER-KING PIN GAUGE OR POSITION VEHICLE ON WHEEL ALIGNMENT TESTER

Follow the specific instructions of the equipment manufacturer.

3. INSPECT CAMBER, CASTER AND STEERING AXIS INCLINATION

Camber, caster and steering axis inclination:

RZN161L Model

RZN1171L Model

RZN191L model

RZN196L model

VZN170L model

VZN195L model

If the steering axis inclination is not within the specified value, after the camber and caster have been correctly adjusted, recheck the steering knuckle and front wheel for bearing or looseness.

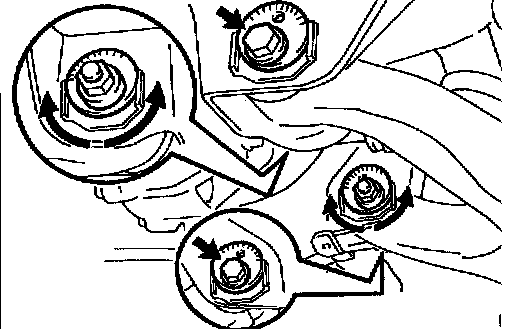

4. ADJUST CAMBER AND CASTER

a. Loosen the front and/or rear adjusting cam nuts.

b. Adjust the camber and caster by front and/or rear adjusting cams (See adjustment chart).

HINT: Try to adjust the camber and caster to the center of the specified values.

c. How to read adjustment chart.

1. Find the wheel alignment standard value applicable for the particular model.

2. Mark the selected standard value on the adjustment chart.

Example:

Camber: 0°10' (0.17°)

Caster: 1°40' (1.67°)

3. Mark the alignment value measured when the vehicle was non-loaded on the adjustment chart.

Example:

Camber: -0°10'(-0.17°)

Caster: 1°40' (1.67°)

4. As shown in the chart, read the distance from the measured value to the standard value, and adjust the front and/or rear adjusting cams accordingly.

Example:

Front cam: -(Shorter) 2.8

Rear cam: -(Shorter) 2.8

d. Torque the front and/or rear adjusting cam nuts.

Torque: 130 Nm (1,325 kgf-cm, 96 ft. lbs.)

Measuring Point Reference:

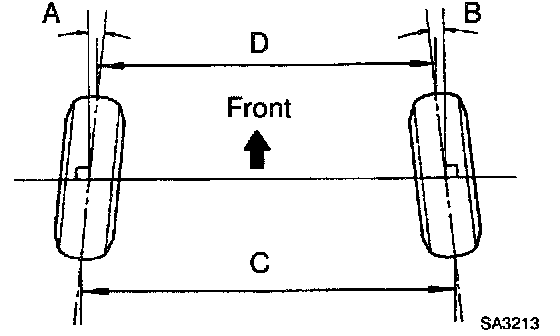

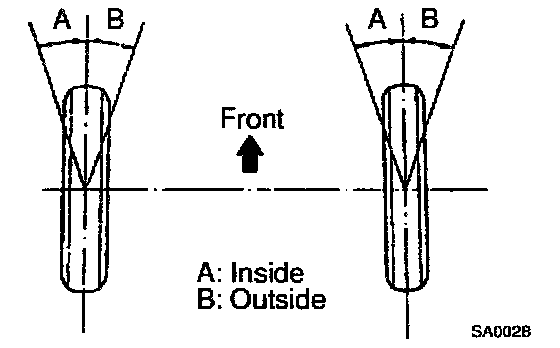

5. INSPECT TOE-IN

Toe-In:

If the toe-in is not within the specified value, adjust the rack ends.

6. ADJUST TOE-IN AND WHEEL ANGLE

HINT: First, check or adjust the lengths of the rack ends, then adjust the toe-in.

Rack end length difference: 1.5 mm (0.059 inch) or less

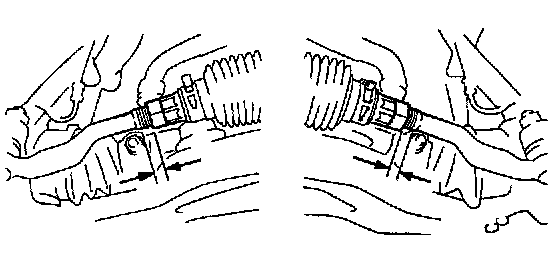

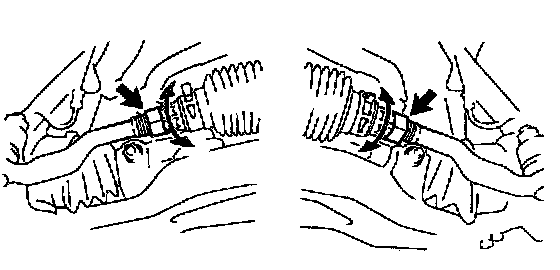

a. Remove the 2 clips.

b. Loosen the tie rod end lock nuts.

c. Turn the right and left rack ends by an equal amount to adjust the toe-in.

HINT: Try to adjust the toe-in to the center of the specified value.

d. Make sure that the lengths of the right and left rack ends are the same.

Rack end length difference: 1.5 mm (0.059 inch) or less

e. Tighten the tie rod end lock nuts.

Torque: 55 Nm (560 kgf-cm, 41 ft. lbs.)

f. Place the boots on the seats and install the clips.

HINT: Make sure that the boots are not twisted.

g. Inspect the wheel angle.

Turn the steering wheel fully and measure the turning angle.

Wheel Turning Angle:

If the right and left wheel turning angles differ from the specified value, readjust the toe-win and wheel angle within the specified value. At this time, the right and left error lengths of the rack end may be less than 1.5 mm (0.059 inch).