Splicing Copper Wire Using Splice Clips

Splice clips are included in the J 38125 Terminal Repair Kit. The Splice Clip is a general purpose wire repair device. It may not be acceptable for applications having special requirements such as moisture sealing.Step One: Open the Harness

If the harness is taped, remove the tape. To avoid wire insulation damage, use a sewing "seam ripper" to cut open the harness (available from sewing supply stores). If the harness has a black plastic conduit, simply pull out the desired wire.

Step Two: Cut the Wire

Begin by cutting as little wire off the harness as possible. You may need the extra length of wire later if you decide to cut more wire off to change the location of a splice. You may have to adjust splice locations to make certain that each splice is at least 40 mm (1-1/2 in) away from other splices, harness branches, or connectors. This will help prevent moisture from bridging adjacent splices and causing damage.

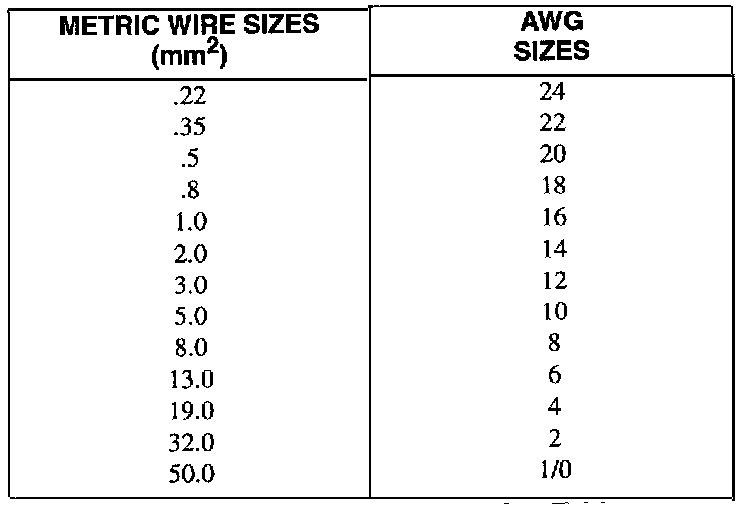

Wire Size Conversion Table:

Step Three: Strip the Insulation

The table shows the commercial (AWG) wire sizes that can be used to replace each of the metric wire sizes. Each AWG size shown is equal to or larger than the equivalent metric wire size.

When replacing wire, use wire of equal or greater size than the original. The wire's insulation must have the same or higher temperature rating.

To find the correct wire size, either find the wire on the schematic page and convert or use an AWG gage.

The type of wire insulation must also be carefully selected. For areas not subject to HI temperatures, such as the passenger compartment, instrument panel or cargo compartment, a general purpose insulation may be used. The most common general purpose insulation is Polyvinyl Chloride (PVC). PVC may be used where temperatures do not exceed 80°C (l76°F).

For applications where higher temperatures are expected, such as the engine compartment, a cross-linked polyethylene insulated wire should be used. Insulex (TM) is one such type; it can withstand temperatures up to 148°C (300°F). Cross-linked polyethylene wire may be used to replace PVC, but not the other way around. Cross-linked polyethylene wire is not resistant to fuel or fuel vapors and should not be used to replace wire on the fuel tank unit or throttle body injector connector, for example. Oxygen sensor leads should not be replaced with cross-linked polyethylene.

Select the correct size opening in the wire stripper or work down from the largest size if you're not sure of wire size. Strip an equal amount of insulation on both pieces of wire. Inspect both pieces for nicks or cut strands; repeat the strip if needed.

Centering The Splice Clip:

Step Four: Crimp the Wires

Select the proper clip to secure the splice. To determine, the proper clip size crimp tool and anvil for the wire being spliced, follow the directions included in the J 38125 Terminal Repair Kit. (On most crimpers, your choice is limited to either a small or large anvil.) Overlap the two stripped wire ends and hold them between your thumb and forefinger as shown in. Then, center the splice clip under the stripped wires and hold it in place.

Crimping The Splice Clip:

^ Open the crimping tool to its full width and rest one handle on a firm flat surface.

^ Center the back of the splice clip on the proper anvil and close the crimping tool to the point where the former touches the wings of the clip.

^ Make sure that the clip and wires are still in the correct position. Then, apply steady pressure until the crimping tool closes.

^ Before crimping the ends of the clip, be sure that:

- The wires extend beyond the clip in each direction.

- No, strands of wire are cut loose.

- No insulation is caught under the clip.

Completing The Crimp:

Crimp the splice again, once on each end. Do not let the crimping tool extend beyond the edge of the clip or you may damage or nick the wires.

Applying The Solder:

Step Five: Solder

Apply 60/40 rosin core solder to the opening in the back of the clip. Follow the manufacturer's instructions for the solder equipment you are using.

Proper First Taping:

Step Six: Tape the Splice

Use splicing tape or duct tape when taping splices. Do not use standard electrical tape. Center and roll the splicing tape. The tape should cover the entire splice. Roll on enough tape to duplicate the thickness of the insulation on the existing wires. Do not flag the tape. Flagged tape may not provide enough insulation, and the flagged ends will tangle with the other wires in the harness.

Proper Second Taping:

If the wire does not belong in a conduit or other harness covering, tape the wire again. Use a winding motion to cover the first piece of tape.