FUEL PUMP UNIT INSPECTION [F2]

id011494801100

Simulation Test

1. Carry out the “Fuel Pump Operation Inspection”, “Fuel Pump Control Inspection”. (See ENGINE CONTROL SYSTEM OPERATION INSPECTION [F2].)

-

• If not as specified, perform the further inspection for the fuel pump unit.

Continuity Inspection

-

Note

-

• Perform the following test only when directed.

1. Complete the “BEFORE REPAIR PROCEDURE”. (See BEFORE REPAIR PROCEDURE [F2].)

2. Disconnect the negative battery cable.

3. Remove the fuel tank. (See FUEL TANK REMOVAL/INSTALLATION [F2].)

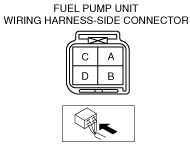

4. Inspect for continuity between fuel pump unit connector terminals B and D.

-

• If there is no continuity, replace the fuel pump . If as specified but the “Simulation Test” is failed, inspect the following:

Open circuit

• GND circuit (fuel pump unit connector terminal D and body ground)

• Power circuit (fuel pump relay connector terminal D and fuel pump unit connector terminal B through common connector)

Short circuit

• Fuel pump relay connector terminal D and fuel pump unit connector terminal B though common connector to ground

5. Repair or replace faulty areas.

6. Install the fuel tank. (See FUEL TANK REMOVAL/INSTALLATION [F2].)

7. Reconnect the negative battery cable.

8. Complete the “AFTER REPAIR PROCEDURE”. (See AFTER REPAIR PROCEDURE [F2].)

Fuel Pump Maximum Pressure Inspection

-

Warning

-

• Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and damage. Always carry out the following procedure with the engine stopped.

-

Note

-

• Perform the following test only when directed.

1. Complete the “BEFORE REPAIR PROCEDURE”. (See BEFORE REPAIR PROCEDURE [F2].)

2. Disconnect the negative battery cable.

3. Connect a fuel pressure gauge to the fuel hose between the pulsation damper and fuel main hose, then plug the opening as shown.

4. Start the fuel pump using the following procedure:

-

Using M-MDS

-

1. Connect the negative battery cable.

2. Connect the M-MDS to the DLC-2.

3. Start the fuel pump using the “FP” simulation function.

-

Caution

-

• Connecting the wrong DLC terminal may possibly cause a malfunction. Carefully connect the specified terminal only.

-

Not using M-MDS

-

1. Short the DLC terminal F/P to body ground using a jumper wire.

2. Connect the negative battery cable.

3. Turn the ignition switch to the ON position, to operate the fuel pump.

5. Measure the fuel pump maximum pressure.

-

• If not as specified, inspect the following:

-

― Fuel pump relay

-

― Fuel filter (low-pressure, high-pressure) for clogging

-

― Fuel line for clogging or leakage

-

Fuel pump maximum pressure

-

500—630 kPa {5.0—6.5 kgf/cm2, 72—92 psi}

6. Stop the fuel pump using the following procedure:

-

Using M-MDS

-

1. Stop the fuel pump using the “FP” simulation function.

-

Not using M-MDS

-

1. Turn the ignition switch to off to stop the fuel pump.

7. Complete the “BEFORE REPAIR PROCEDURE”. (See BEFORE REPAIR PROCEDURE [F2].)

8. Disconnect the negative battery cable.

9. Disconnect the fuel pressure gauge.

10. Connect the negative battery cable.

11. Complete the “AFTER REPAIR PROCEDURE”. (See AFTER REPAIR PROCEDURE [F2].)

Fuel Pump Hold Pressure Inspection

-

Warning

-

• Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and damage. Always carry out the following procedure with the engine stopped.

-

Note

-

• Perform the following test only when directed.

1. Complete the “BEFORE REPAIR PROCEDURE”. (See BEFORE REPAIR PROCEDURE [F2].)

2. Disconnect the negative battery cable.

3. Connect a fuel pressure gauge to the fuel hose between the pulsation damper and fuel main hose, then plug the opening as shown.

4. Start the fuel pump using the following procedure:

-

Using M-MDS

-

1. Connect the negative battery cable.

2. Connect the M-MDS to the DLC-2.

3. Start the fuel pump using the “FP” simulation function.

-

Caution

-

• Connecting the wrong DLC terminal may possibly cause a malfunction. Carefully connect the specified terminal only.

-

Not using M-MDS

-

1. Short the DLC terminal F/P to body ground using a jumper wire.

2. Connect the negative battery cable.

3. Turn the ignition switch to the ON position, to operate the fuel pump.

5. Operate the fuel pump for 10 s.

6. Stop the fuel pump using the following procedure:

-

Using M-MDS

-

1. Stop the fuel pump using the “FP” simulation function.

-

Not using M-MDS

-

1. Turn the ignition switch to off to stop the fuel pump.

7. Measure the fuel pump hold pressure after 5 min.

-

-

Fuel pump hold pressure

-

More than 340 kPa {3.5 kgf/cm2, 50 psi}

8. Complete the “BEFORE REPAIR PROCEDURE”. (See BEFORE REPAIR PROCEDURE [F2].)

9. Disconnect the negative battery cable.

10. Disconnect the fuel pressure gauge.

11. Reconnect the negative battery cable.

12. Complete the “AFTER REPAIR PROCEDURE”. (See AFTER REPAIR PROCEDURE [F2].)