FICD SOLENOID VALVE INSPECTION [WLT-1, WLT-2]

id011496017000

System Inspection

1. Carry out the “FICD System Inspection”. (See ENGINE CONTROL SYSTEM OPERATION INSPECTION [WLT-1, WLT-2].)

2. If not as specified, perform the further inspection for the FICD solenoid valve No.1, No.2.

Airflow Inspection

-

Note

-

• Perform the following test only when directed.

1. Disconnect the negative battery cable.

2. Remove the FICD solenoid valve No.1, No.2. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [WLT-1, WLT-2].)

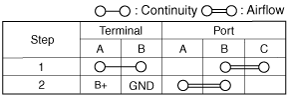

3. Inspect for airflow between ports of the solenoid valve.

4. If not as specified, replace the faulty FICD solenoid valve.

-

• If as specified but “System Inspection” is failed, inspect following:

Vacuum hose improper routing, kinks or leakage.

-

Open circuit

-

• Ground circuit (FICD solenoid valve No.1 connector terminal B and PCM connector terminal C)

• Ground circuit (FICD solenoid valve No.2 connector terminal B and PCM connector terminal P)

• Power circuit (FICD solenoid valve No.1 connector terminal A and engine switch connector terminal IG1)

• Power circuit (FICD solenoid valve No.2 connector terminal A and engine switch connector terminal IG1)

-

Short circuit

-

• Ground circuit (FICD solenoid valve No.1 connector terminal B and PCM connector terminal C)

• Ground circuit (FICD solenoid valve No.2 connector terminal B and PCM connector terminal P)

• Power circuit (FICD solenoid valve No.1 connector terminal A and engine switch connector terminal IG1 to ground)

• Power circuit (FICD solenoid valve No.2 connector terminal A and engine switch connector terminal IG1 to ground)

5. Repair or replace faulty areas.

6. Install the FICD solenoid valve No.1, No.2.

7. Reconnect the negative battery cable.