DUAL-MASS FLYWHEEL INSPECTION [S15M-D, S15MX-D]

id0510008020b3

-

Caution

-

• Do not rework the dual-mass flywheel if it is distorted.

• Do not clean the dual-mass flywheel with any kind of fluid. Clean the dual-mass flywheel with a dry cloth only.

• Do not clean the gap between the primary and secondary mass. Only clean the bolt connection surface and the clutch surface.

1. Remove the manual transmission. (See TRANSMISSION REMOVAL/INSTALLATION [S15M-D].)(See TRANSMISSION AND TRANSFER REMOVAL/INSTALLATION [S15MX-D].)

2. Remove the clutch cover and clutch disc. (See CLUTCH UNIT REMOVAL/INSTALLATION [S15M-D, S15MX-D].)

3. Inspect the rotation of the dual-mass flywheel for play.

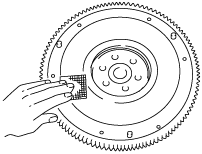

- (1) Lock the dual-mass flywheel using the SST (49 E011 1A0).

-

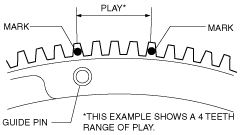

- (2) Rotate the secondary flywheel clockwise by hand until resistance can be felt.

-

- (3) Mark the guide pin position on the ring gear of the flywheel.

-

- (4) Rotate the secondary flywheel counterclockwise by hand until resistance can be felt.

-

- (5) Mark the guide pin position on the ring gear of the primary flywheel again.

-

- (6) Verify that the play is within the range of 4 teeth.

-

-

-

Caution

-

• It may not be possible to rotate the secondary flywheel due to the functionality of the dual-mass flywheel.

In this case, the dual-mass flywheel can be considered normal by reason of the play being within the range of 4 teeth.

4. Remove the dual-mass flywheel.

-

Note

-

• Correct slight scratches and discoloration using sandpaper.

• Inspect the runout of the surface that contacts the clutch disc with the dual-mass flywheel installed to the crankshaft.

5. Inspect the dual-mass flywheel.

-

― Cracks

― Worn ring gear teeth

― Chipped or cracked ring gear teeth

― Surface that contacts the clutch disc for scratches, nicks, and discoloration.

-

• If there is any malfunction, replace the dual-mass flywheel.

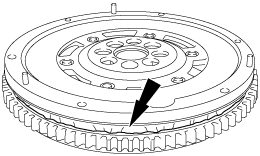

6. Inspect for locating dowels touching the primary mass of the dual-mass flywheel.

-

Caution

-

• Make sure that the three locating dowels are installed.

-

• If the locating dowels are touching the primary mass of the dual-mass flywheel, replace the dual-mass flywheel with a new one.

7. Visually inspect the ring gear on the dual-mass flywheel.

-

• If there is any damage, replace the dual-mass flywheel.

8. Inspect the welded area of the dual-mass flywheel for grease leakage.

-

• If there is grease leakage, replace the dual-mass flywheel.

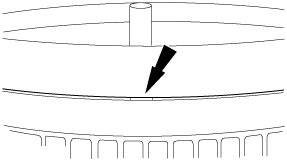

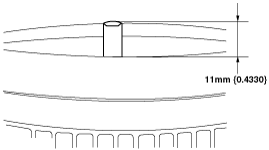

9. Inspect the dual-mass flywheel for the amount of guide pin projection.

-

• If not within the specification, replace the dual-mass flywheel.

10. Inspect the dual-mass flywheel for cracks.

-

• If there are cracks, replace the dual-mass flywheel.