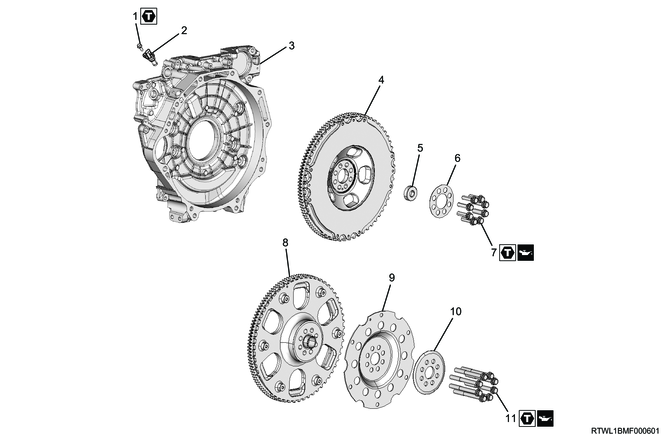

1. Component views

Flywheel

Part name

- Bolt

- CKP sensor

- Flywheel housing

- Flywheel (Manual transmission models)

- Bearing

- Flywheel washer

- Bolt

- Flywheel (Automatic transmission models)

- Flexible plate

- Flexible plate washer

- Bolt

Tightening torque

1: 5.0 N・m { 0.5 kgf・m / 44 lb・in }

7-1: 40 N・m { 4.1 kgf・m / 30 lb・ft }

7-2: 60 to 90 °

11-1: 40 N・m { 4.1 kgf・m / 30 lb・ft }

11-2: 120 °

11-3: 30 to 60 °

2. Flywheel installation

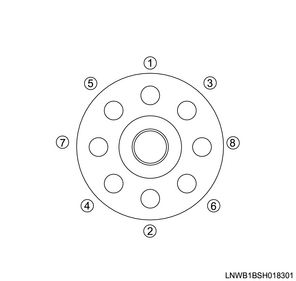

1. Manual transmission models

1) Apply engine oil to the threaded portions and seating surfaces of the bolts.

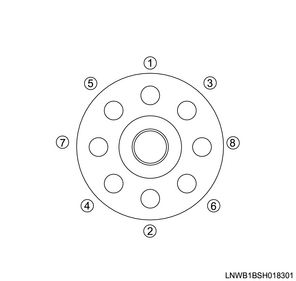

2) Temporarily tighten the washer and flywheel to the crankshaft in the order shown in the diagram.

Note

- Verify that the washer does not rotate on the flywheel.

Legend

- Flywheel

- Washer

- Bolt

Caution

- Do not damage the flywheel sensor rotor section.

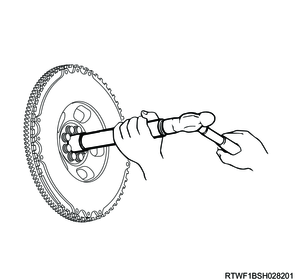

3) Install the special tool to the starter motor installation section of the flywheel housing.

SST: 5-8840-3174-0 - crankshaft stopper

4) Final tighten the flywheel to the crankshaft in the order shown in the diagram.

Tightening torque: 40 N・m { 4.1 kgf・m / 30 lb・ft } 1st time

Tightening Angle : 60 to 90 ° 2nd time

5) Remove the special tool from the starter motor installation section of the flywheel housing.

6) Place the pilot bearing so that it crosses the crankshaft bearing installation hole perpendicularly.

7) Install the pilot bearing to the flywheel using the special tool.

Note

- Drive in the pilot bearing outer race using a hammer.

SST: 5-8522-0024-0 - pilot bearing installer

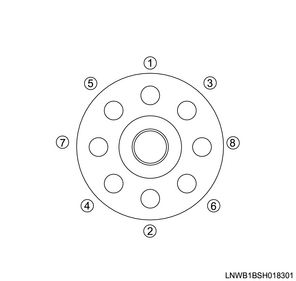

2. Automatic transmission models

1) Apply engine oil to the threaded portions and seating surfaces of the bolts.

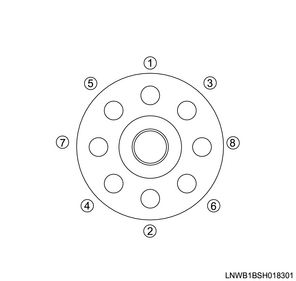

2) Temporarily tighten the following parts to the crankshaft in the order shown in the diagram.

- Washer

- Flexible plate

- Flywheel

Caution

- Do not damage the flywheel sensor rotor section.

3) Install the special tool to the starter motor installation section of the flywheel housing.

SST: 5-8840-3174-0 - crankshaft stopper

4) Final tighten the flywheel to the crankshaft in the order shown in the diagram.

Tightening torque: 40 N・m { 4.1 kgf・m / 30 lb・ft } 1st time

Tightening Angle : 120 ° 2nd time

Tightening Angle : 30 to 60 ° 3rd time

Caution

- The total rotation angle should be 150 to 180°.

5) Remove the special tool from the starter motor installation section of the flywheel housing.

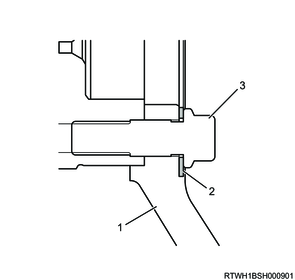

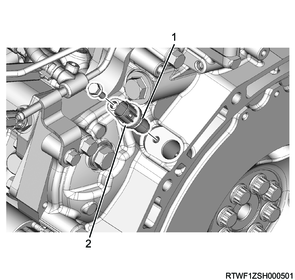

3. CKP sensor installation

1) Apply soapy water to the O-ring.

2) Install the CKP sensor to the flywheel housing.

Tightening torque: 5.0 N・m { 0.51 kgf・m / 44.3 lb・in }

Legend

- O-ring

- CKP sensor

3) Connect the connector to the CKP sensor.